Gravity flow type oil spout mouth detector

A fuel injection nozzle and self-flow technology, which is applied in the field of fuel injection nozzle detectors, can solve the problems of oil blockage, unreachable hydraulic oil, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

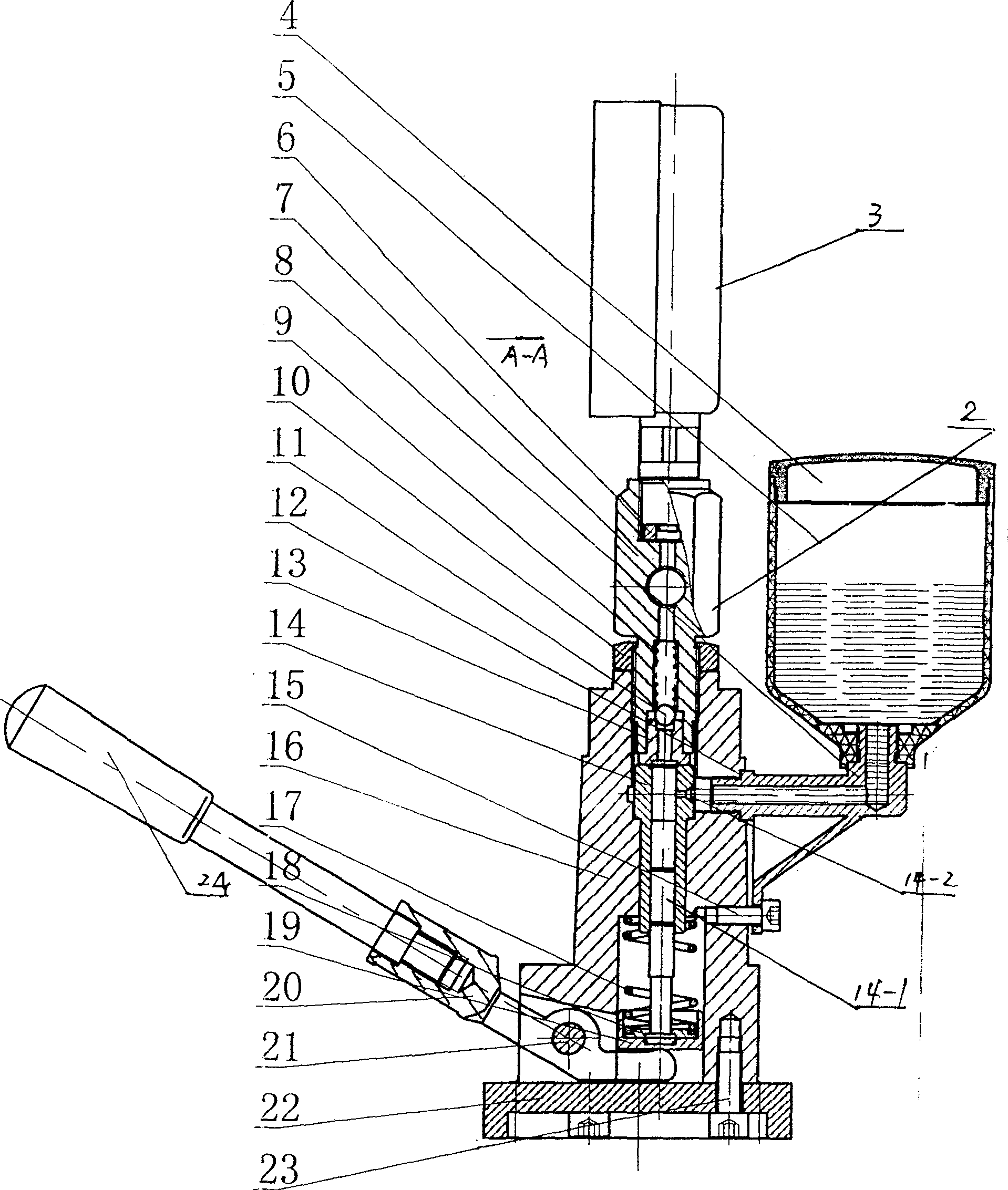

[0007] The present invention will be further described below in conjunction with accompanying drawing:

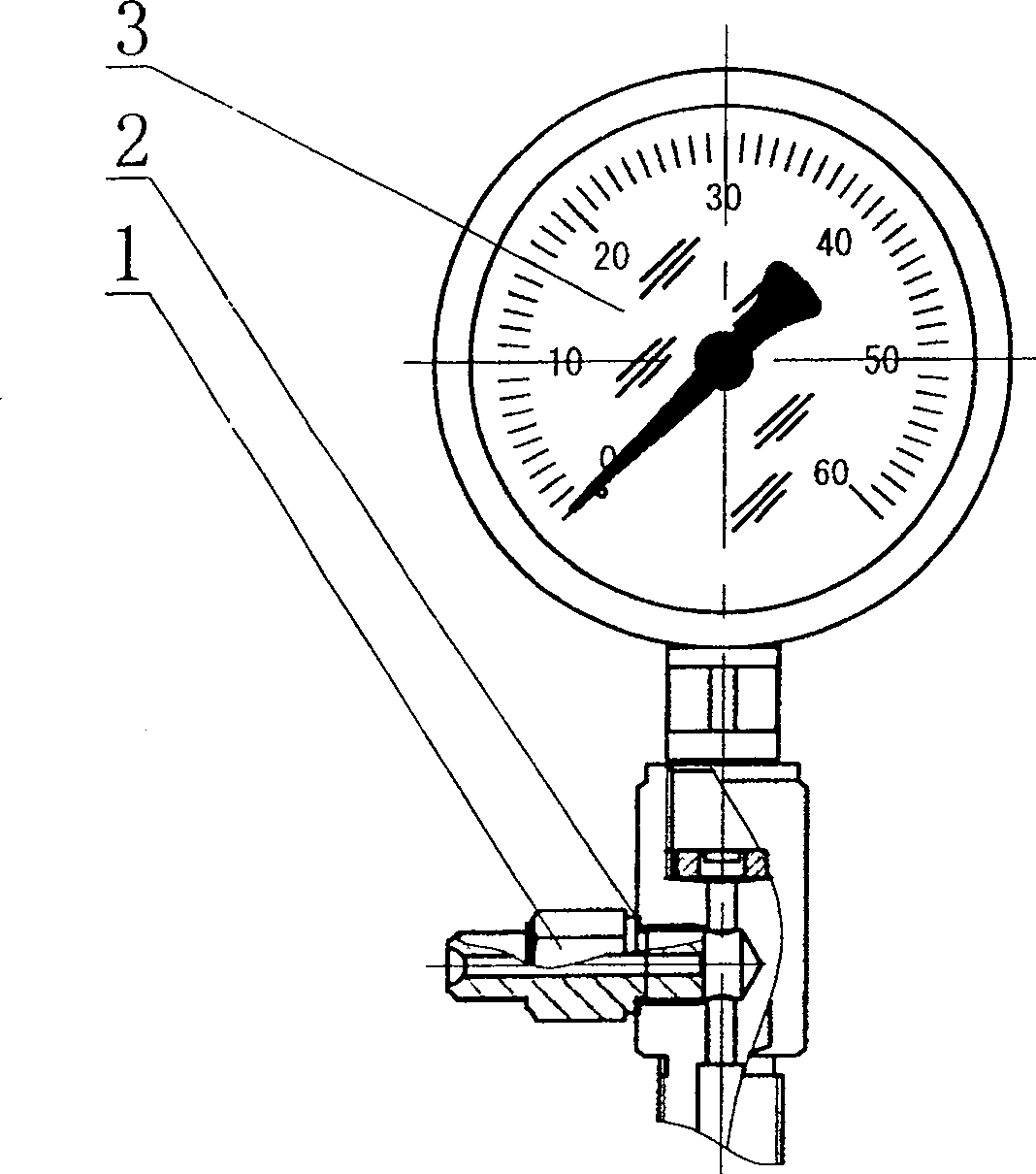

[0008] See attached figure 1 , 2 , the base 22 and the base 16 are fixed together by screws 23, the pin 21 fixed on the base 16 is flexibly connected to the lever 20, one end of the lever 20 is screwed into the handle 24, and the head of the other end is against the piston tray 19, the piston tray 19 Hold up the piston 14-1, the retaining ring 18 passes through the piston 14-1 and puts it in the piston tray 19 to buckle the piston 14-1, the spring 17 is arranged between the base 16 and the retaining ring 18, and the piston 14-1 is inside The plunger sleeve 14 is fixed in the hole of the machine base 16, and its oil inlet hole 14-2 is aligned with the oil cup seat 8, and the valve seat 13 is placed on the upper end of the plunger sleeve 14 and is pressed tightly and sealed by the screwed pressure gauge joint 7, There is a steel ball 11 on the upper opening of the valve sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com