Overrunning clutch device used in vehicle

An overrunning clutch and clutch technology, applied in clutches, one-way clutches, mechanical equipment, etc., can solve the problems of large energy transmission loss, large energy loss, and easy wear and tear of components, and achieve energy saving, simple manufacturing process, and mechanism. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

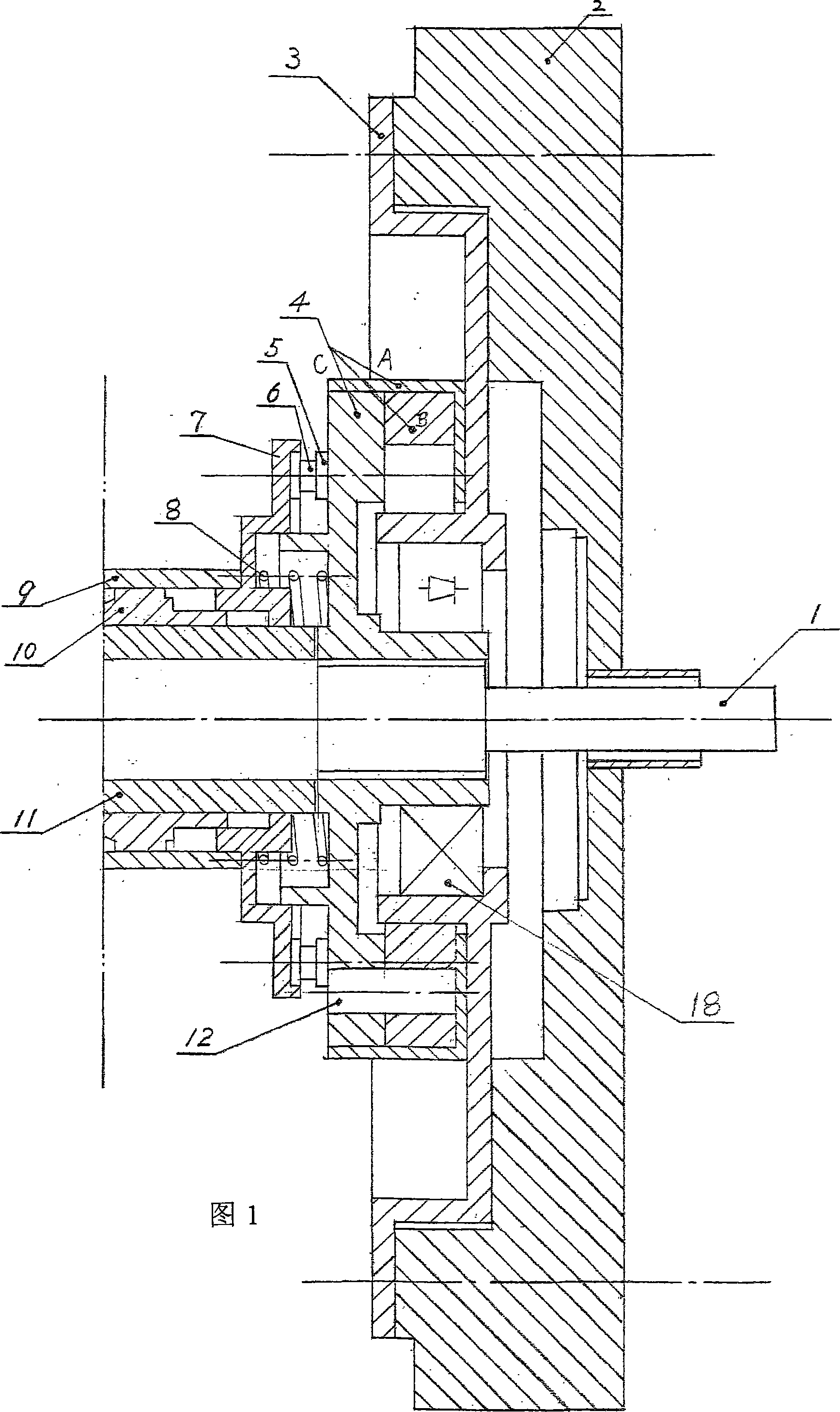

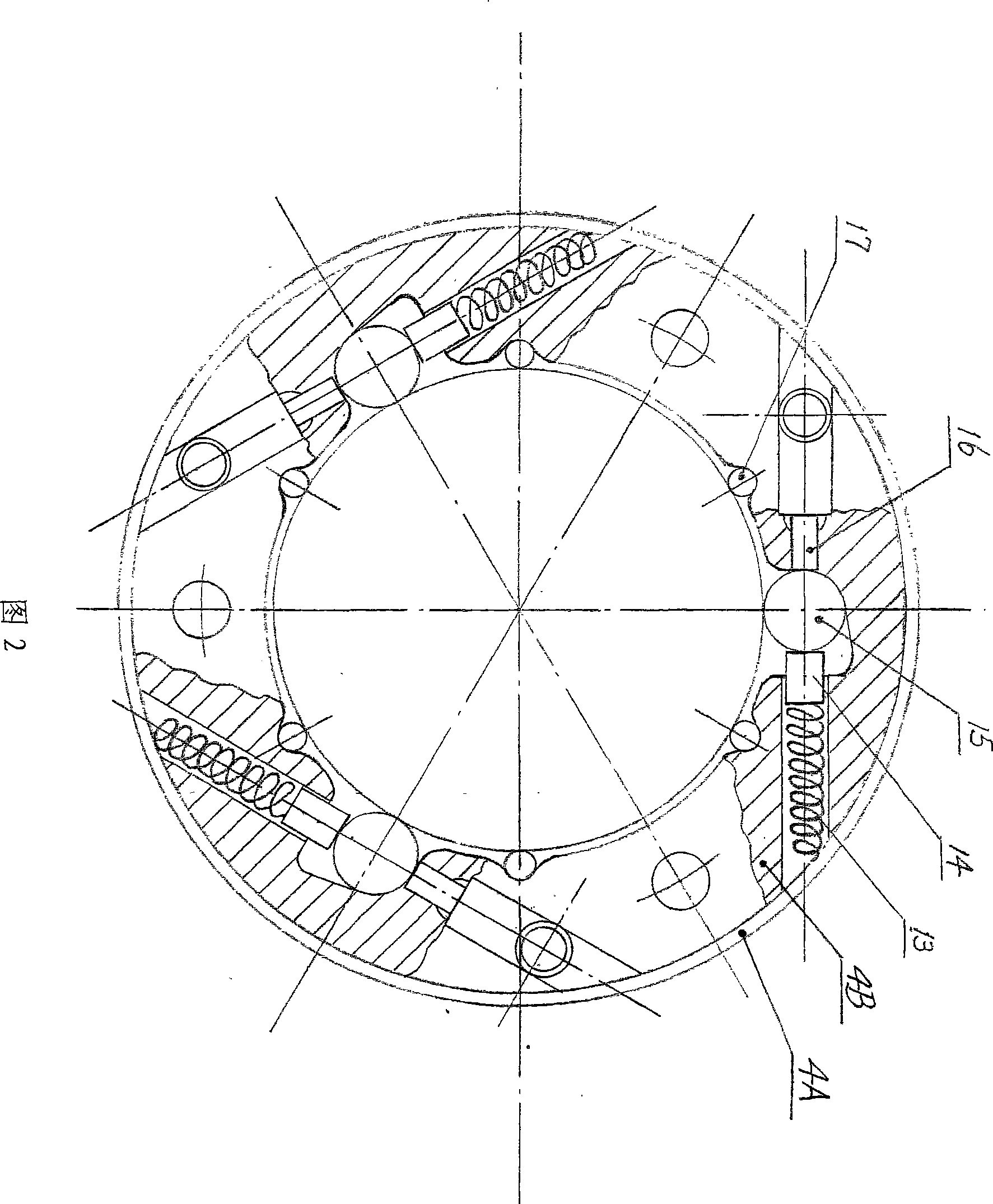

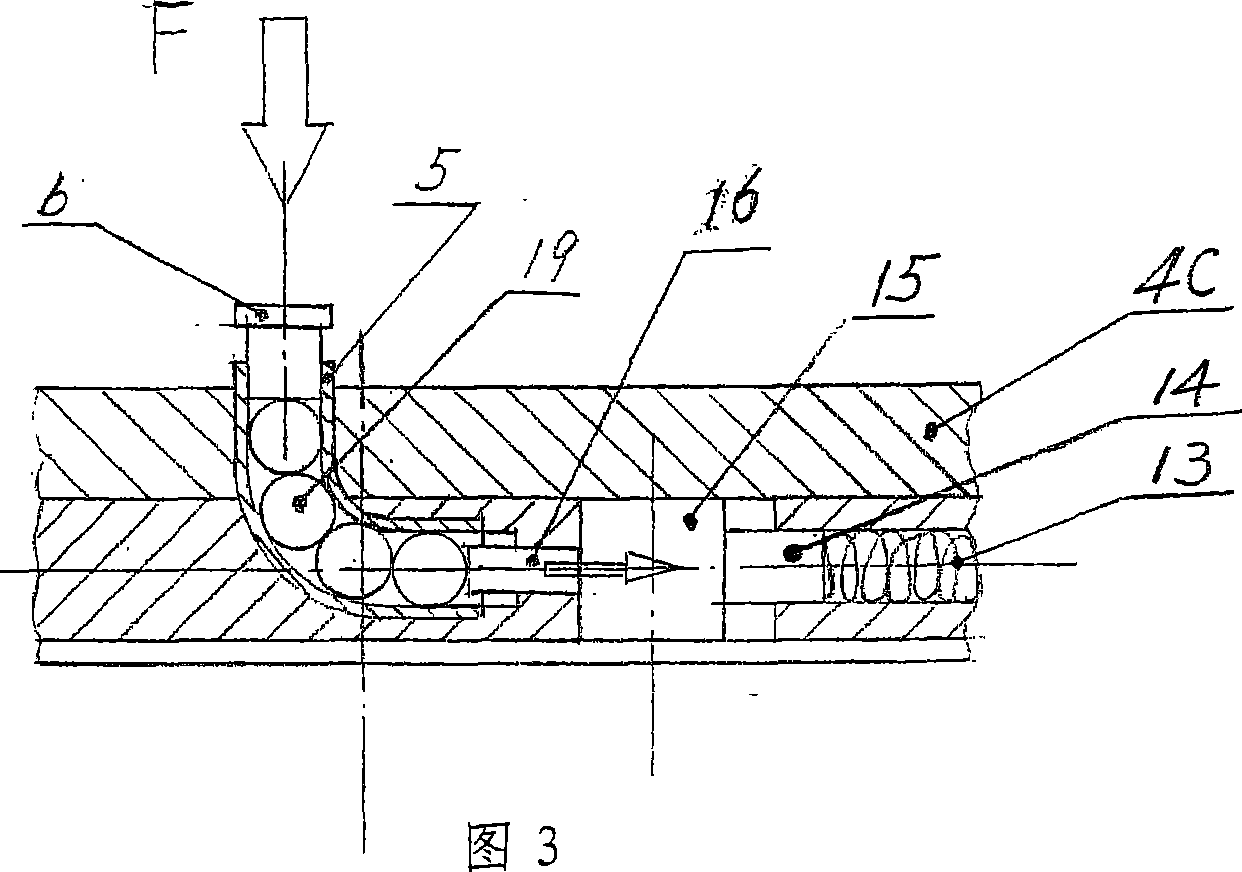

[0009] Accompanying drawing is embodiment of the present invention.

[0010] Below in conjunction with appending the content of the present invention is further described:

[0011] With reference to Fig. 1, Fig. 2, shown in Fig. 3, a kind of overrunning clutch device for automobile, comprises motor for automobile, and motor drives flywheel 2 to rotate, and the rotating disc 3 that is fastened on the flywheel 2 outputs with the same power, and the rotating circle The central shaft sleeve 11 of the disc 3 is set on the outer ring of the bearing 18. The clutch disc 4B in the clutch device is driven by the overrunning roller 15 under the action of the spring components 13 and 14, and the central shaft of the disc 3 drives the clutch disc. At least four small rollers 17 arranged on the inner circumference of 4B rotate accordingly; the toothed keyboard 4C fixed on the inner ring of the bearing 18 is driven by three pins 12 to rotate, and the inner cavity of the guide tube seat 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com