Exhaust hood

A technology of exhaust hood and exhaust pipe, applied in the field of exhaust hood, can solve the problems of incomplete gas discharge, reduced work efficiency, long operation time, etc., and achieve the effect of being beneficial to physical health and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

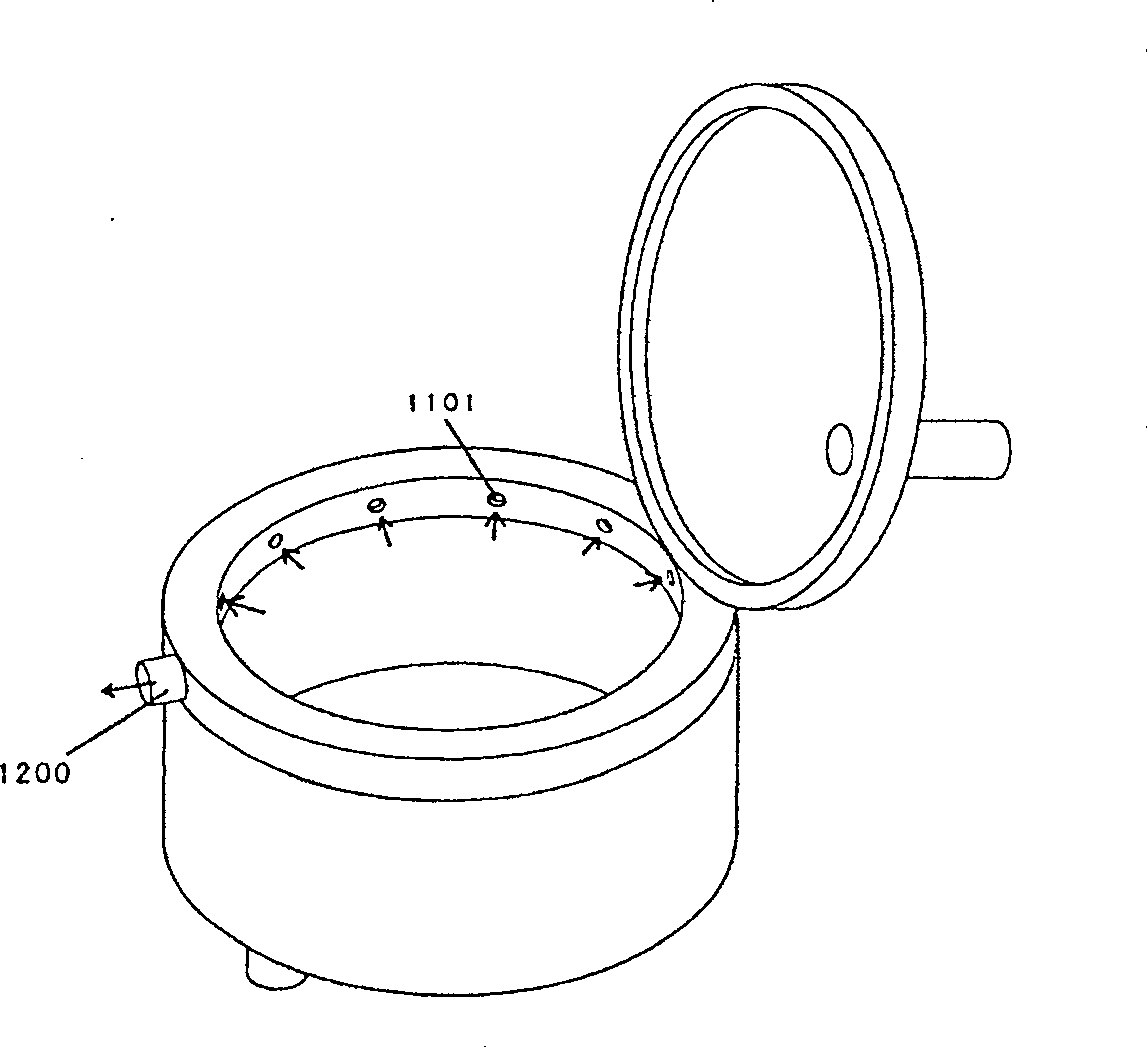

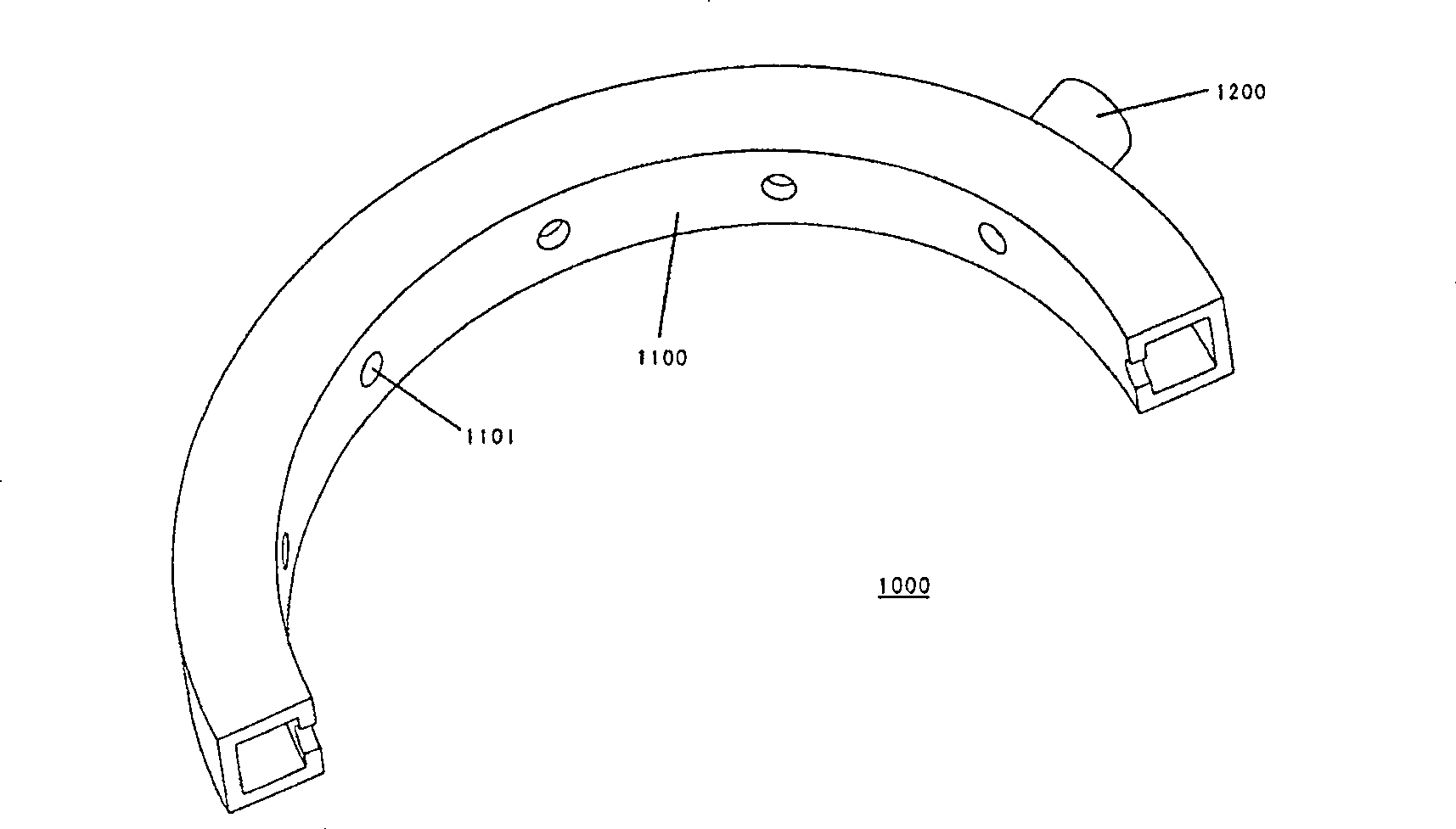

[0019] Embodiment 1: exhaust hood 1000

[0020] image 3 It is one of the embodiments of the present invention: a schematic diagram of an exhaust hood 1000 installed around the opening of the reaction chamber; the exhaust hood 1000 is a surrounding type exhaust hood, Figure 4 It is a structural schematic diagram of the exhaust hood 1000. It should be noted that the opening and closing of the reaction chamber top cover is not affected after the exhaust hood 1000 is installed; Figure 4 As shown, the exhaust hood 1000 installed in the present invention is a circumferential hollow sleeve 1100 and a pipeline 1200 communicated with the circumferential hollow sleeve 1100, and the inner wall of the hollow sleeve 1100 is provided with There are a plurality of exhaust holes 1101, and the pipeline 1200 is connected with a vacuum suction device (not shown in the figure), image 3 The direction indicated by the arrow in the figure is the direction in which the harmful gas is drawn out ...

Embodiment 2

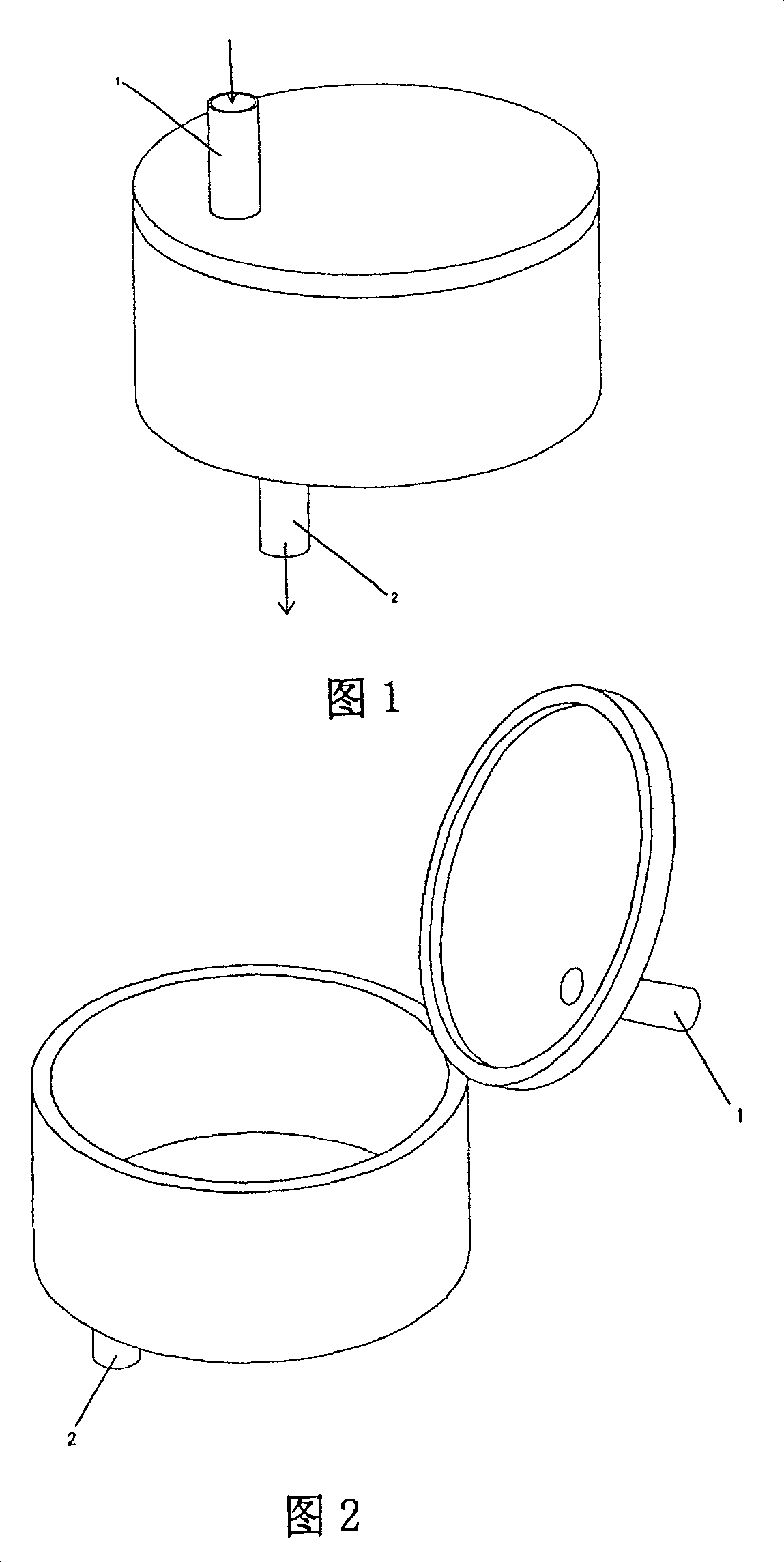

[0023] Embodiment 2: Exhaust device

[0024] In order to strengthen the vacuum suction effect of the exhaust gas in the reaction chamber, the present invention also provides another embodiment: that is, on the basis of the first embodiment above, a vertical exhaust ( EXHAUST) tube 1300, such as Figure 5 Shown is the structural representation of embodiment two, and an exhaust hood 1000 adds an exhaust pipe 1300 to form the structural representation of the exhaust device; The exhaust pipe 1300 is connected with a vacuum suction device (not shown), when the When the exhaust pipe 1300 is started together with the exhaust hood 1000, since the exhaust pipe 1300 can directly discharge the waste gas that rises to the central position above the opening of the closed reaction chamber, the exhaust hood 1000 is mainly responsible for removing the waste gas from the closed reaction chamber. Exhaust air is exhausted around the opening, thus making the exhaust effect more pronounced.

...

Embodiment 3

[0026] Embodiment Three: Exhaust Equipment

[0027] On the basis of the above embodiments, in order to achieve the purpose of reducing equipment costs, another embodiment of the present invention can also be derived, such as Figure 6It is a structural schematic diagram of the third embodiment of the present invention: the exhaust equipment contains a plurality of exhaust devices 2000 as described in the second embodiment, and the exhaust equipment is suitable for work sites with multiple closed reaction chambers, wherein each reaction chamber The hollow casing 1100 of the exhaust hood 1000 of the chamber is placed around the opening of the closed reaction chamber, and each exhaust pipe 1300 is arranged above the opening of the closed reaction chamber; the plurality of exhaust pipes 1300 are collected into a general After the exhaust pipe 3100, the total exhaust pipe 3100 is connected with a vacuum suction device (not shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com