Micro-heating device used in planar optical waveguide thermo-optic devices and manufacture method therefor

A technology of plane light waves and optical devices, applied in the directions of optical waveguides, optical waveguides, coupling of optical waveguides, instruments, etc., can solve problems such as the limitation of thermo-optic devices, reduce thermal power consumption, simplify the production process, and have a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

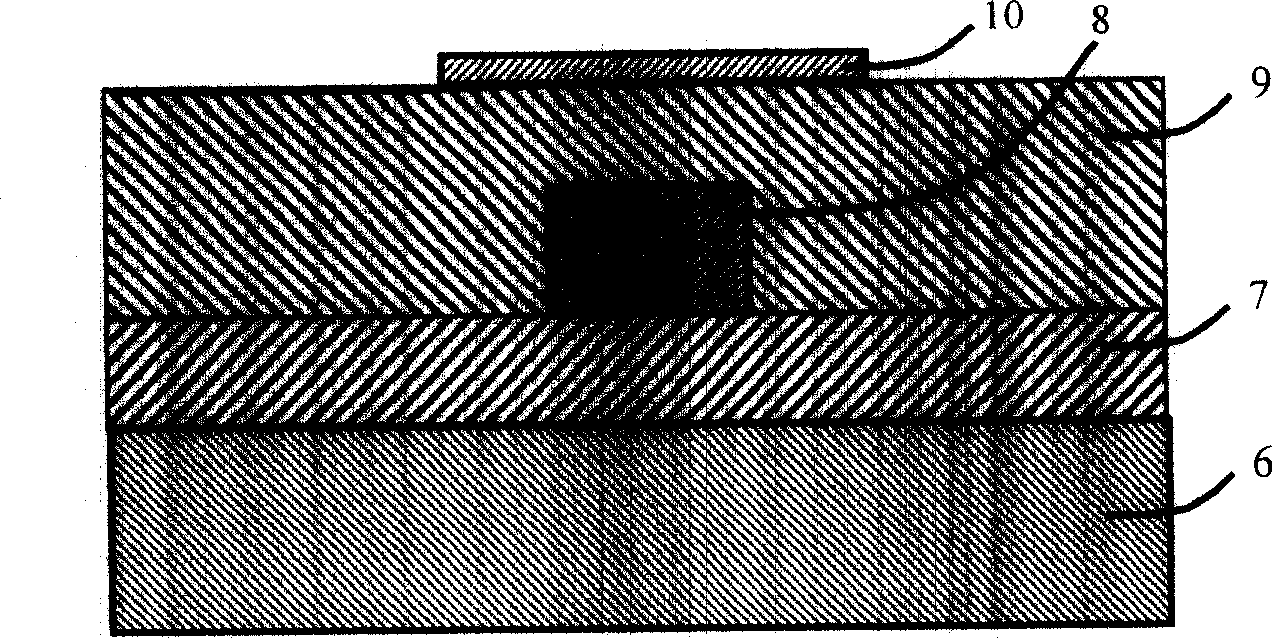

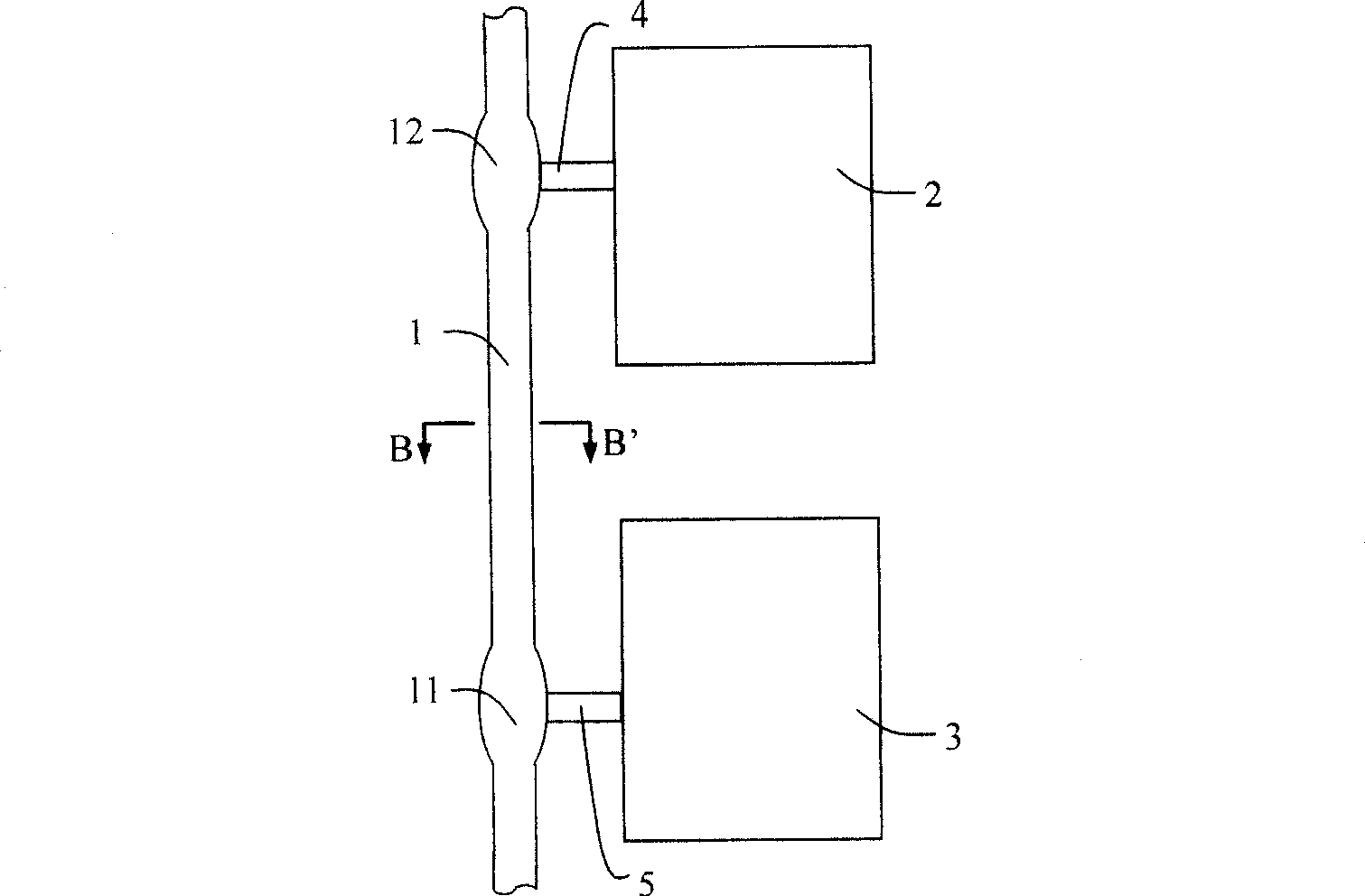

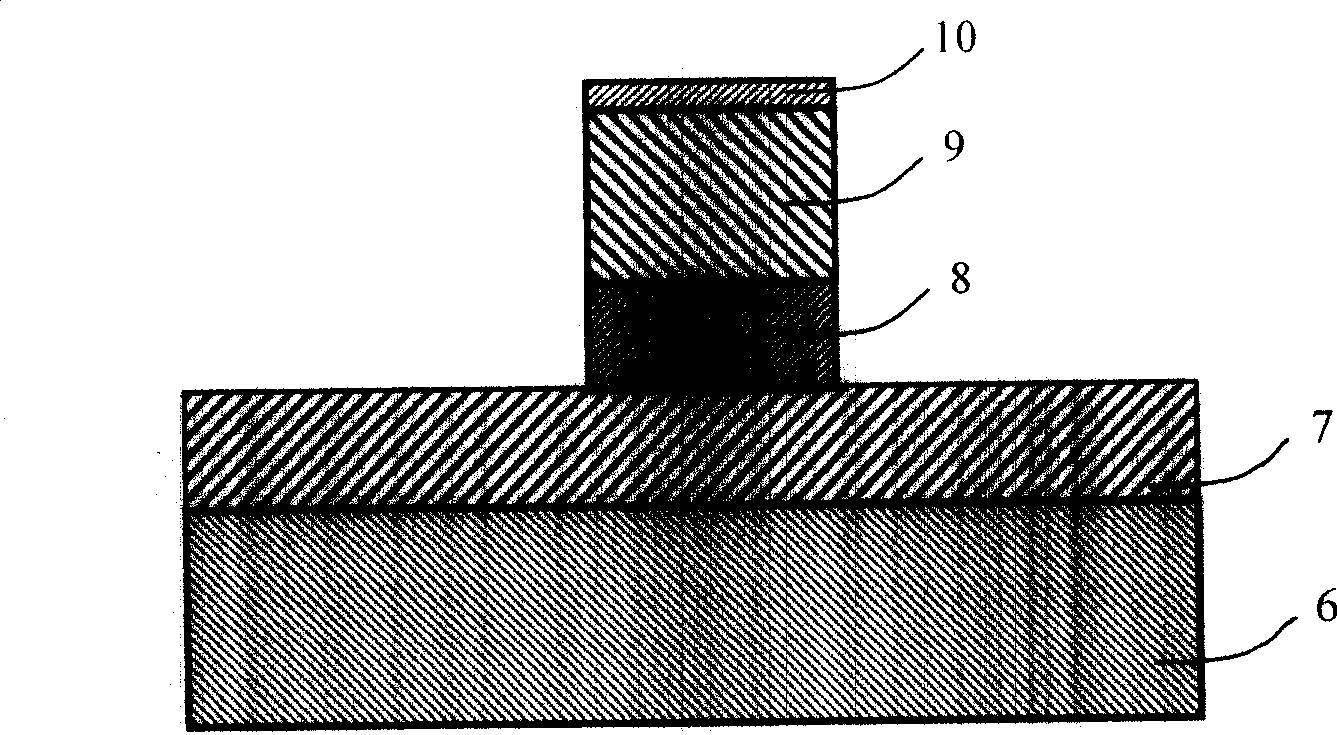

[0021] refer to figure 2 , the micro-heating device for planar optical waveguide thermo-optical devices of the present invention, comprising an optical transmission channel 1, two contact points 2, 3 for connecting to an external power supply, and two connections connecting the optical transmission channel and the two contact points Arm 4, 5. The said optical transmission channel 1 (such as image 3 (shown) consists of a substrate 6 and an isolation layer 7 , a core layer 8 , an upper cladding layer 9 and a thermal electrode thin film 10 deposited on the substrate sequentially from bottom to top. The optical transmission channel 1 is a ridge-type optical waveguide, and the upper cladding layer 9, the hot electrode film 10 and the core layer 8 have the same width. The two contact points 2, 3, the connecting arms 4, 5 and the optical transmission channel 1 have the same layer structure in the height direction (see Figure 4 ).

[0022] In order to reduce the optical power l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com