Aqueous polyurethane dispersing liquid as adhesive and paint and its preparation

A technology of water-based polyurethane and dispersion liquid, which is applied in the field of water-based polyurethane dispersion liquid, and can solve the problems of instantaneous bond strength and final bond strength reduction, energy consumption, and low-strength coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

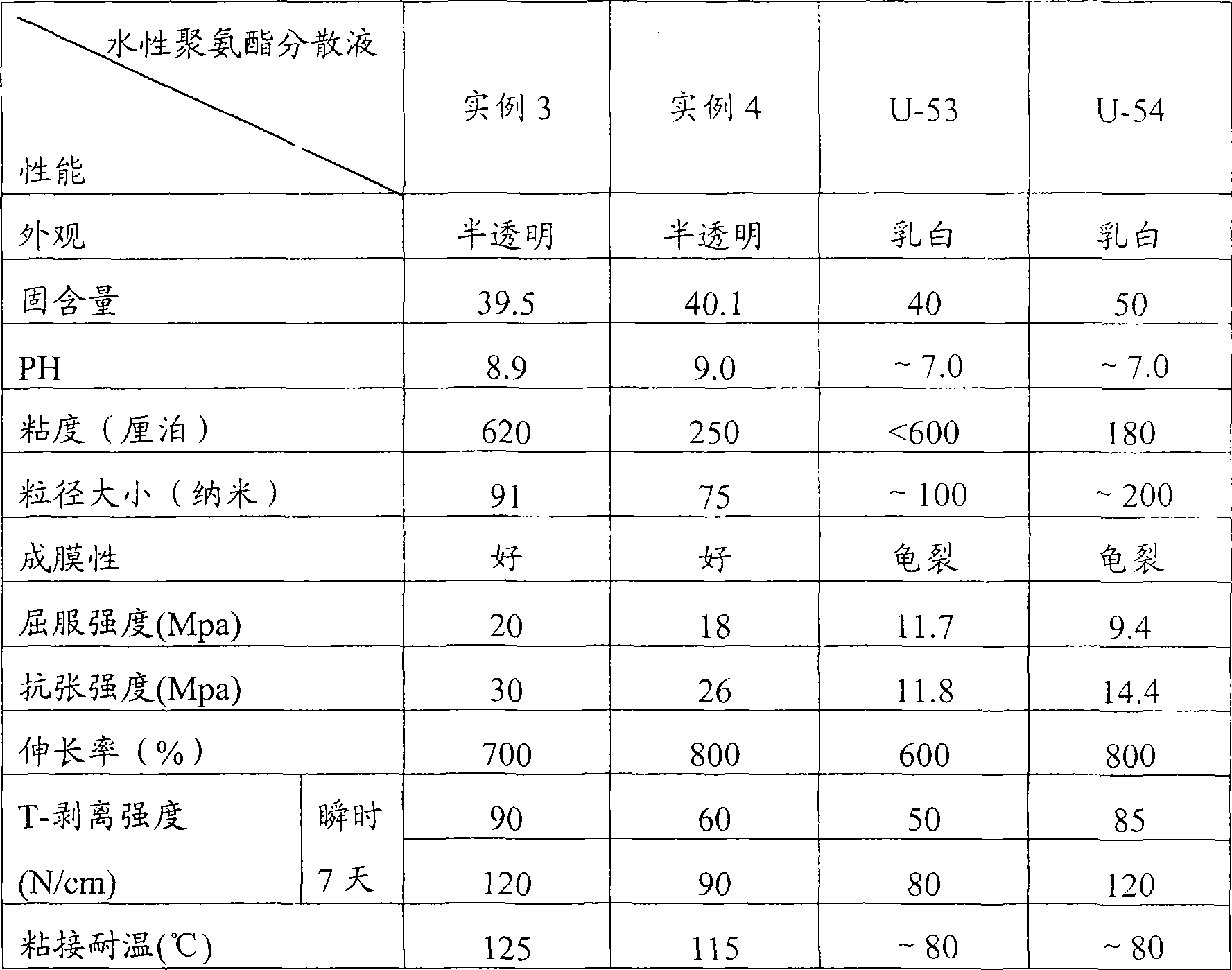

[0099] Examples 1 and 2 illustrate a mixture of three diisocyanates composed of HDI and two ring-bearing diisocyanates (IPDI and TMXDI), in the presence of a small amount of solvent, a prepolymer synthesized by reacting with DMPA and polyester diol in one step , can successfully prepare a stable aqueous polyurethane dispersion. Compared with U.S. Patent 1. USP6147155, this patent description uses the mixture of HDI and ring-banded diisocyanate (such as IPDI), in the presence of a large amount of solvent (such as NMP of more than 20% of the total amount of prepolymer), and DMPA and polyester diisocyanate Prepolymers synthesized in one step by alcohol reaction cannot be successfully prepared into stable aqueous polyurethane dispersions.

Embodiment 1

[0101] 219.2 g of polyester diol (prepared from 1,6-hexanediol, neopentyl glycol and adipic acid, Molecular weight 2000) and 12.1 grams of DMPA with 9.1 grams of triethylamine, 30.42 grams of HDI, 19.98 grams of IPDI and 21.96 grams of TMXDI, in the presence of 16 grams of acetone, reacted at 70 ° C for 3 hours. The resulting neutralized isocyanate-terminated prepolymer was dispersed in 450 grams of water with rapid stirring, followed by the slow addition of a solution of 12.9 grams of EDA in 22 grams of water. The dispersion was continuously stirred at 60-65°C for 2 hours to obtain a stable translucent aqueous polyurethane dispersion with the following properties:

[0102] Solid content (%): 40.1

[0103] pH: 8.9

[0104] Viscosity (centipoise): 540

[0105] Particle size (nm): 89

Embodiment 2

[0107] In the same glass reactor in Example 1, 210 grams of polyester diol (prepared by 1,4-butanediol and adipic acid, molecular weight 2000), 14.1 grams of DMPA and 2.25 grams of 1,4-butanediol, With 42.34 g of HDI, 23.31 g of IPDI and 5.12 g of TMXDI, in the presence of 17.8 g of acetone, react at 70°C for 3 hours, then add 10.1 g of triethylamine for neutralization for 15 minutes. The neutralized isocyanate-terminated prepolymer was dispersed in 529 grams of water with rapid stirring, followed by the slow addition of a solution of 7.6 grams of EDA in 30 grams of water. The dispersion was continuously stirred at 60-65°C for 2 hours to obtain a stable aqueous polyurethane dispersion with the following properties:

[0108] Solid content (%): 35.1

[0109] pH: 9.1

[0110] Viscosity (centipoise): 350

[0111] Particle size (nm): 180

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com