Thermal flow density measuring device under adverse environment experiment

A heat flux density and harsh environment technology, applied in the direction of measuring devices, measuring heat, calorimeters, etc., can solve the problems of unbalanced three-phase voltage and low precision, eliminate noise voltage interference, solve long-term drive and impedance matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

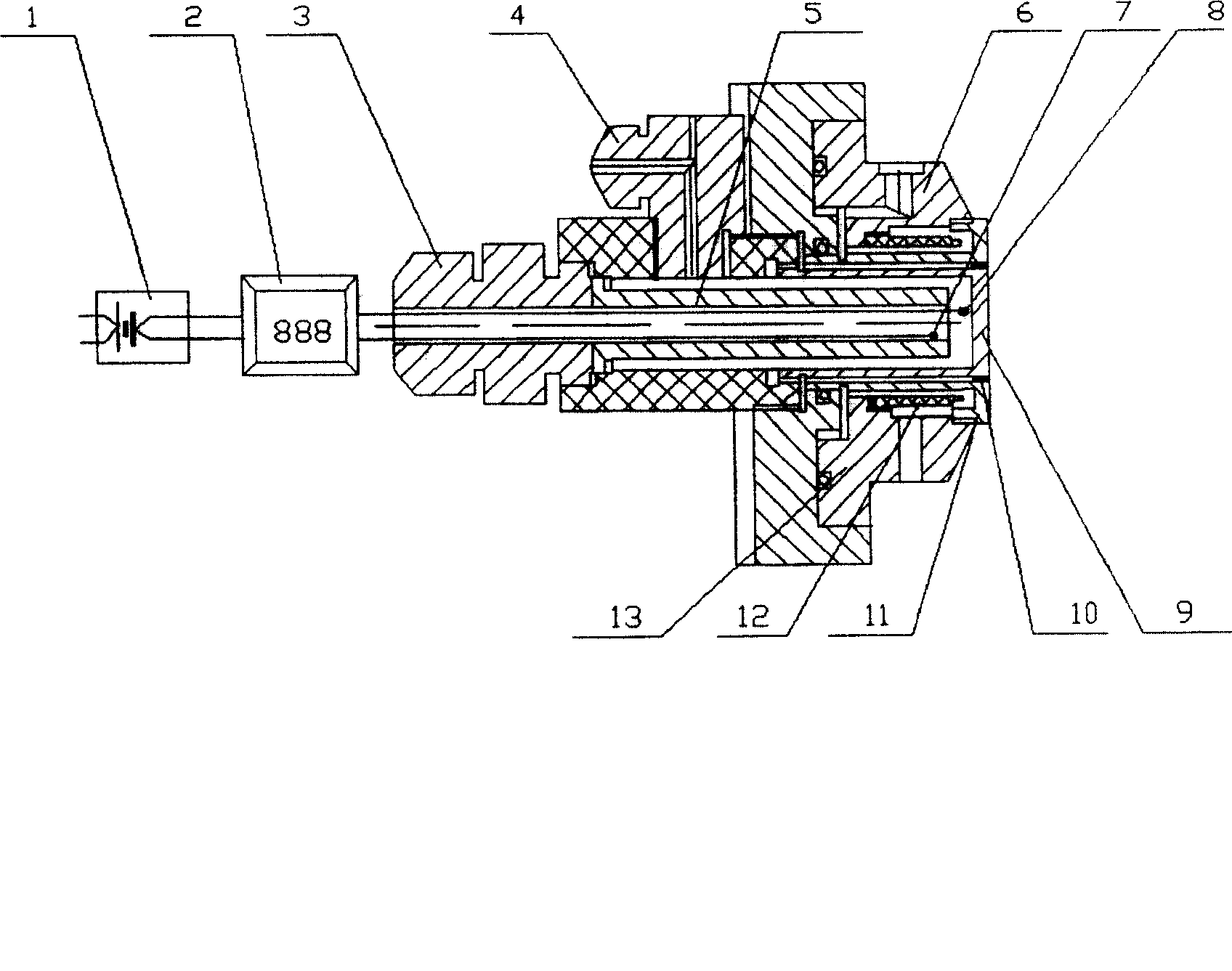

[0020] Below in conjunction with accompanying drawing example the present invention is done in detail:

[0021] The composition of the experimental heat flux density measurement device in harsh environments includes a heating element 11, which is a hollow ring-shaped member, and a probe core 9 is welded in the center of the ring. The probe core is a hollow cylindrical member, and a water pipe 5 is arranged in the cavity. In the cavity formed by the water pipe and the probe core, industrial thermocouples 7 and 8 are respectively arranged on the side close to the incoming flow end of the flow field. 3 and water outlet 4, there is a cooling water channel in the heating part, and there is a water retaining part 12 in the cooling water channel that separates the water channel into two channels inside and outside. The water outlet part 13 of the industrial thermocouple is connected with the thermocouple signal acquisition device 2, and the signal of the thermocouple signal acquisiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com