Power conversion device using matrix converter

A technology of power conversion device and frequency converter, which is applied in the direction of output power conversion device, AC power input conversion to AC power output, conversion equipment that can be converted to DC without intermediate conversion, etc., and can solve the problem of rising wiring inductance, etc. problem, to achieve the effect of suppressing overvoltage, realizing miniaturization, and canceling the snubber circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

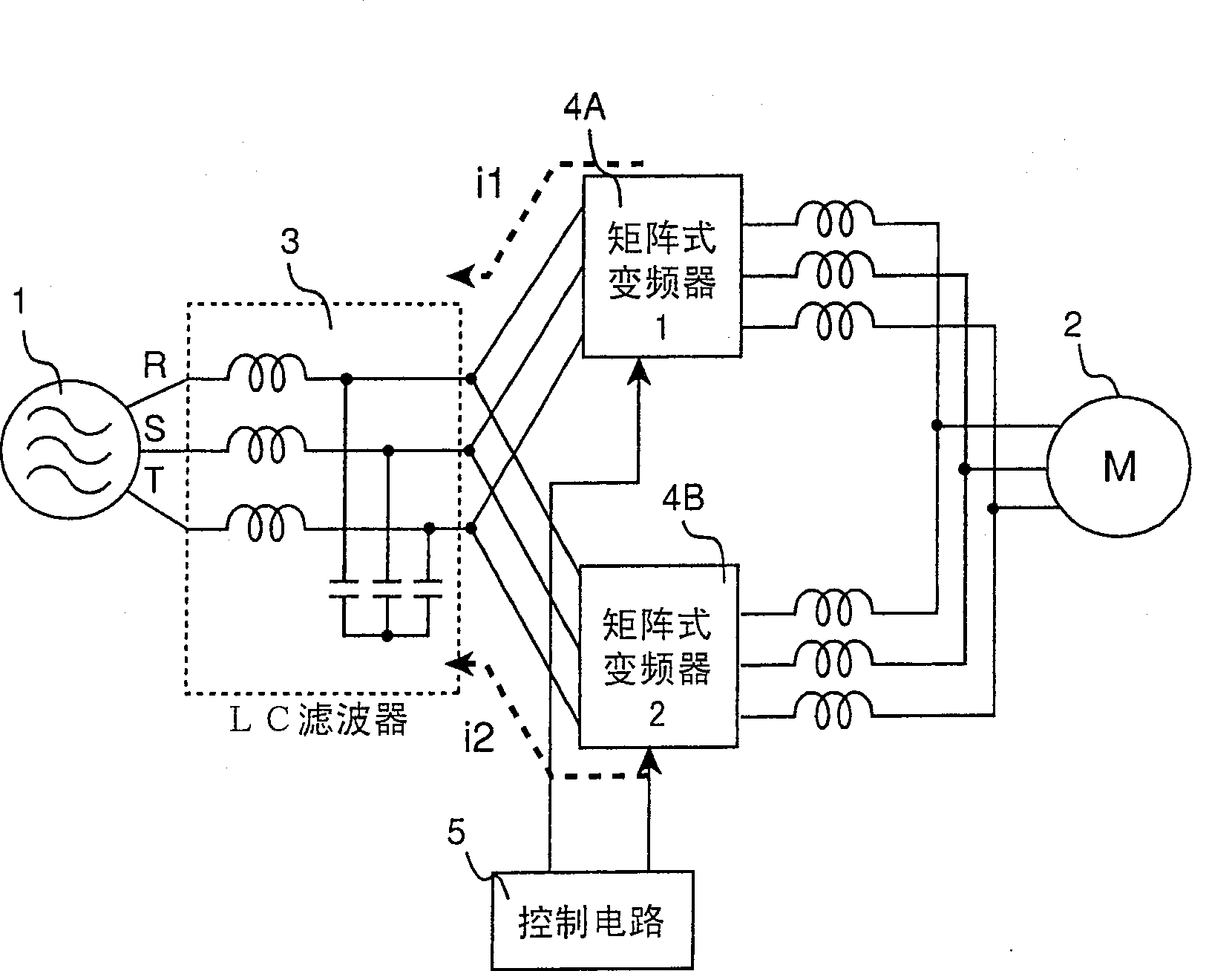

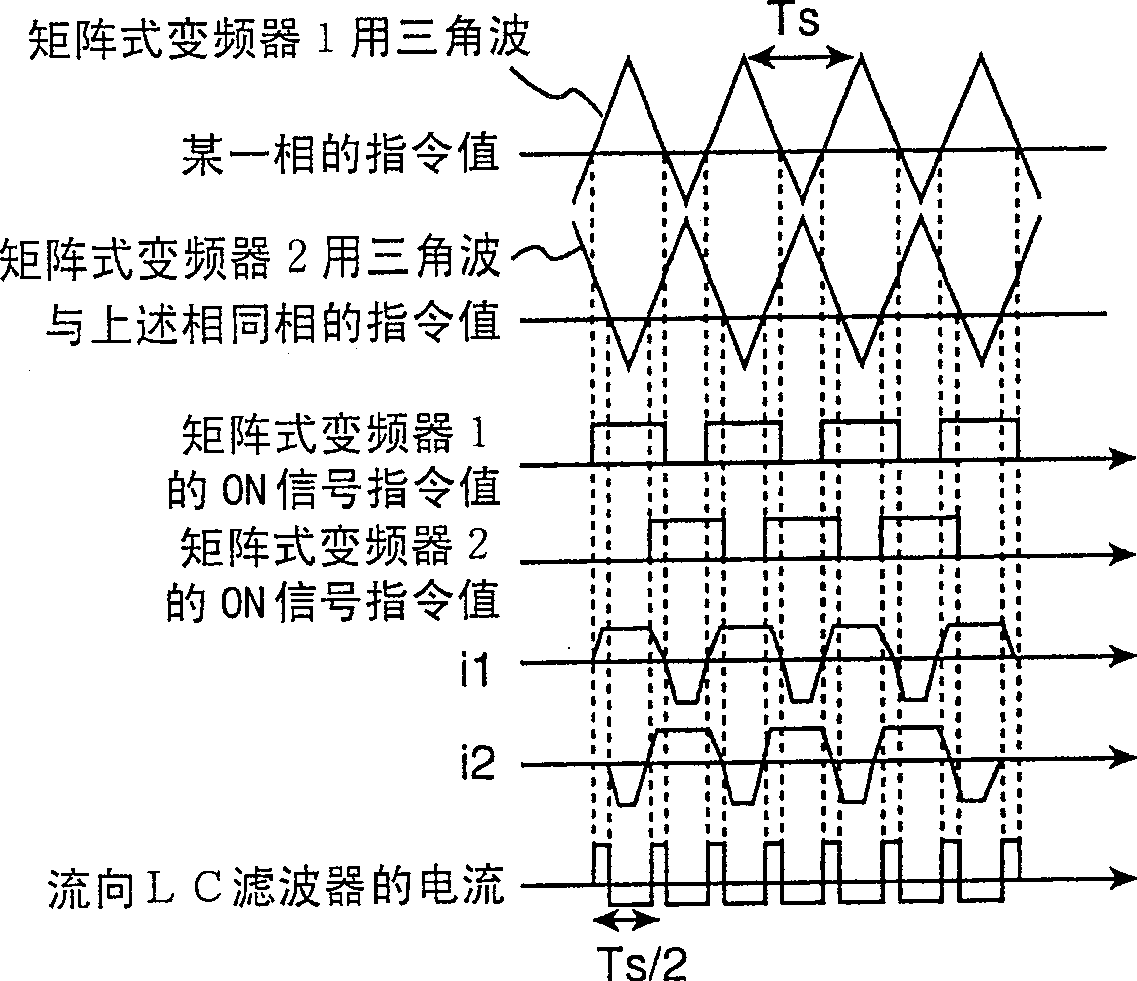

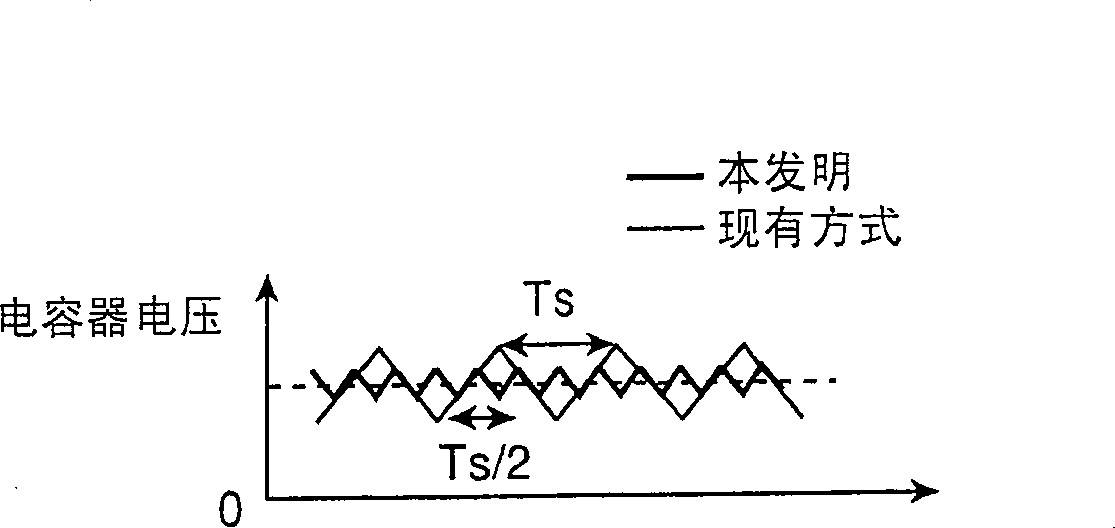

[0034] The following reference Figure 1 to Figure 12 The implementation form of the first invention will be described.

[0035] figure 1 It is a power conversion device using a matrix frequency converter according to the first embodiment of the present invention. The power conversion device consists of a commercial power source 1, a motor as a load 2, an LC filter 3, a matrix frequency converter 1 (4A), and a matrix frequency converter. The inverter 2 (4B) and the control circuit 5 for driving the matrix inverters 4A and 4B are constituted. In addition, i1 represents the current flowing into the LC filter 3 from the matrix inverter 1 (4A), and i2 represents the current flowing into the LC filter 3 from the matrix inverter 2 (4B). In the existing converter system, the commercial power source is first converted into direct current through a rectifier, and then converted into alternating current at any frequency through an inverter. At this time, in order to stabilize the direct c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com