Method of preparing high-strength thin-crystal two-phase steel

A dual-phase steel, fine-grained technology, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

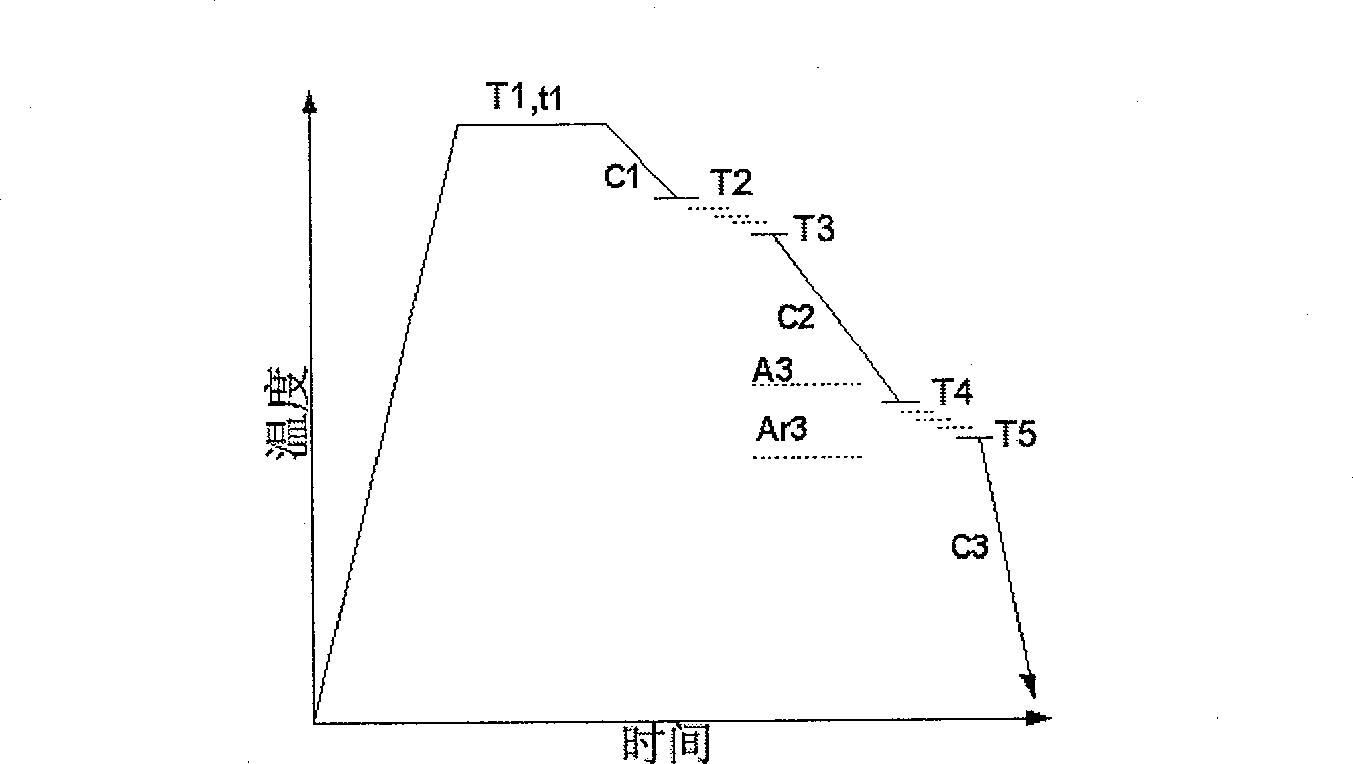

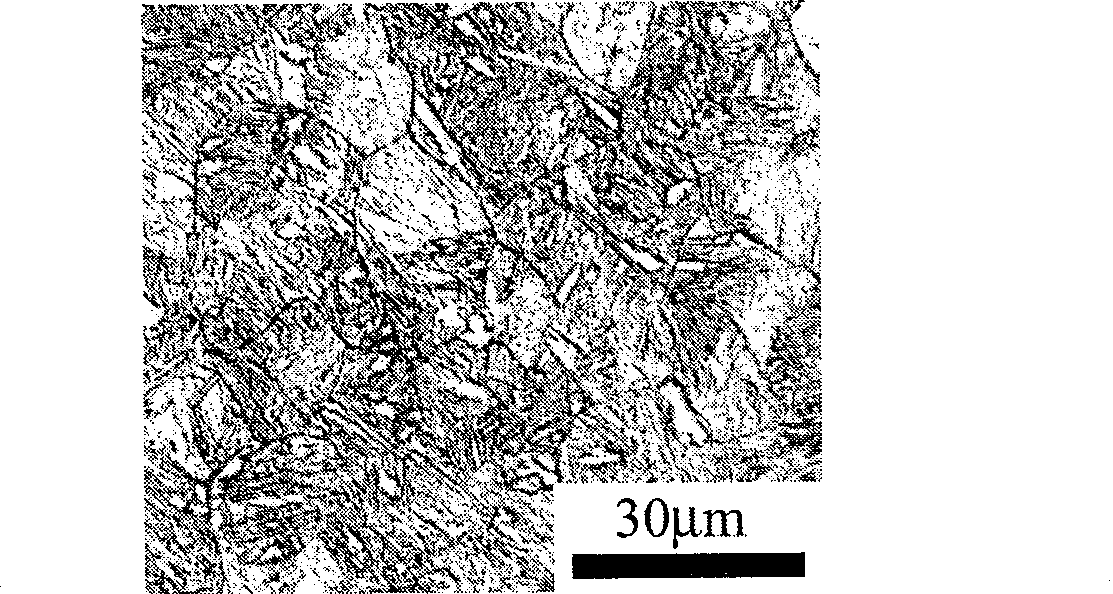

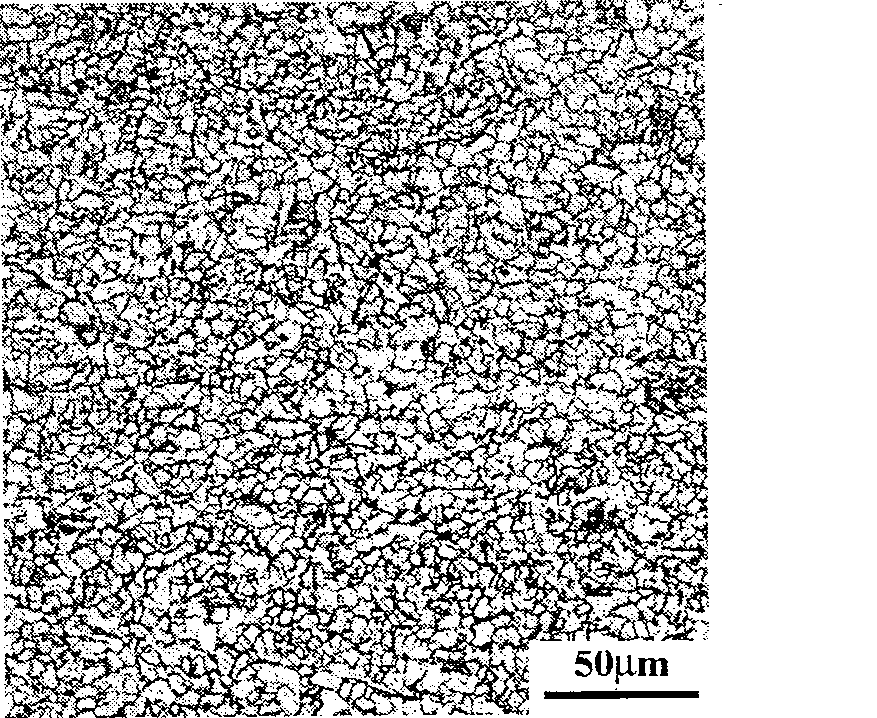

[0013] Select the low-carbon steel whose chemical composition is: 0.087%C, 1.24%Mn, 0.35%Si, and the balance is Fe. Its A was measured by thermal dilatation method 3 is 860°C, cooling rate C2 is 30°C / s, Ar 3 It is 760°C. After heating the low-carbon steel to 1200°C for 5 minutes, at 1100°C and 1000°C in the temperature range of T2~T3 respectively for 1s -1 strain rate deformation, the deformation amount of each pass is 30%, obtained as follows figure 2 The recrystallized austenite structure around 25 microns is shown. Afterwards, cool at a cooling rate of 30°C / s to 820°C in the temperature range of T4~T5, and -1 The deformation rate is 30% in two passes, the interval between the two passes is 1s, and the cooling rate is 60°C / s to room temperature, and the obtained image 3 In the fine-grained dual-phase structure shown, the average grain size of ferrite is about 3.94 microns, the average size of martensitic islands is about 2.56 microns, and the volume fraction is about ...

Embodiment 2

[0015] The chemical composition of the selected steel grade is the same as in Example 1. Heat the low-carbon steel to 1200°C for 5 minutes and then heat it at 1100°C and 1000°C in the temperature range of T2~T3 for 1s -1 strain rate deformation, the deformation amount of each pass is 30%, obtained as follows figure 2 The recrystallized austenite structure around 25 microns is shown. After that, cool down to 800°C at a cooling rate of 15°C / s and take 10s -1 The deformation rate is 30% in two passes, the interval between the two passes is 10s, and the cooling rate is 60°C / s to room temperature, and the obtained Figure 4 In the fine-grained dual-phase structure shown, the average grain size of ferrite is about 4.09 microns, the average size of martensitic islands is about 3.33 microns, and the volume fraction is about 10%.

Embodiment 3

[0017] The hot-rolled slab of ordinary low-carbon manganese steel is used, and its chemical composition is: 0.09%C, 1.4%Mn, 0.35%Si, and the balance is Fe. The original thickness of the blank is 15mm. The multi-pass reversible rolling test was carried out on a 350 four / two-high reversible hot strip experimental rolling mill, and the rolling speed used was 500mm·s -1 . The hot rolling process is: 1200°C for 30 minutes, then air-cooled to 1100°C to start rolling, two passes of rolling with a reduction of 30%, the interval between passes is 5s, and the temperature after the second pass is 1000°C about. After that, air cooling (cooling rate is about 12°C / s) to 840°C for two consecutive rolling passes with a reduction of 30%, the interval between passes is 3s, the final rolling temperature is 790°C, and water cooling after rolling. Figure 5 It is the SEM morphology of the fine-grained dual-phase structure obtained under this process. The average grain size of ferrite is about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com