Heat treatment process for large size as-cast high-Nb TiAl-base alloy to obtain complete lamellar structure

A heat treatment method and base alloy technology, applied in the field of intermetallic compounds, can solve the problems of increased segregation severity, unfavorable mechanical properties of alloys, uneven distribution of alloying elements, etc. Small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

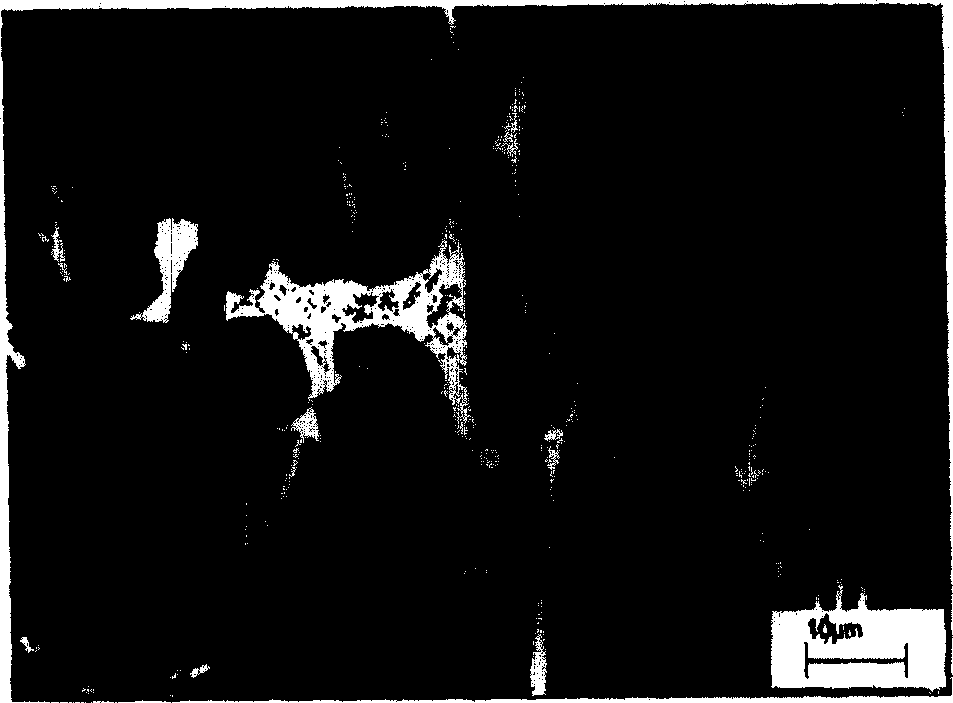

[0016] The chemical composition of the alloy used in the experiment is Al: 45, Nb: 8.5, W: 0.2, B: 0.2, Y: 0.02, the balance is Ti (atomic percentage at.%), and a composite of vacuum consumable + condensed shell Smelted by smelting process. figure 1 with figure 2 The original structure of the alloy sample before heat treatment is shown. From the figure, it can be seen that the large-size as-cast high-niobium TiAl-based alloy is composed of γ / α2 lamellae and a small amount of γ and β distributed between the lamellae. (B2) Near-lamellar structure composed of grains. According to the previous research of this research group, there are three kinds of segregation in the alloy structure, which are defined as: S-segregation ( figure 2 The arrows in have pointed out several areas: black contrast), β-segregation and α-segregation (such as image 3 Shown), their presence greatly reduces the mechanical properties of the alloy.

[0017] Put an alloy sample with a size of 10×10×10 mm in a c...

Embodiment 2

[0020] Put the alloy sample with the same alloy structure and size of 40×40×40 mm in the crucible in the crucible and heat it for 30 hours in the heat treatment furnace at the furnace temperature of 1350℃, then take out the sample and put it into the furnace immediately. Keep the temperature in the heat treatment furnace at 1050°C for 45 minutes, and finally take the sample out and cool it to room temperature in the air. Observe the evolution process of the tissue at different times of heat preservation.

[0021] The experimental results show that the alloy sample can be kept at 1350°C for 30 hours to obtain a uniform full lamella structure, and the average grain size of the lamella cluster is 240 microns.

Embodiment 3

[0023] Put an alloy sample with the same alloy structure and size of 60×60×60 mm as in Example 1 in a crucible and put it in a heat treatment furnace at a furnace temperature of 1370°C for 18 hours, then take out the sample and immediately put it in the furnace temperature Keep the temperature in the heat treatment furnace at 1050°C for 45 minutes, and finally take the sample out and cool it to room temperature in the air. Observe the evolution process of the tissue at different times of heat preservation.

[0024] The experimental results show that the alloy sample can be kept at 1370℃ for 18 hours to obtain a uniform full-lamella structure, and the average grain size of the lamellar cluster is 185 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com