Preparation method of TiAl-based alloy with fine fully lamellar microstructure

A technology of base alloy and layer, which is applied in the field of preparation of TiAl base alloy, can solve the problems of unsuitability for industrial production, uneven thermal deformation structure, cracking of sample surface, etc., achieve low production cost, increase room temperature tensile strength, The effect of reducing heat treatment temperature and holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

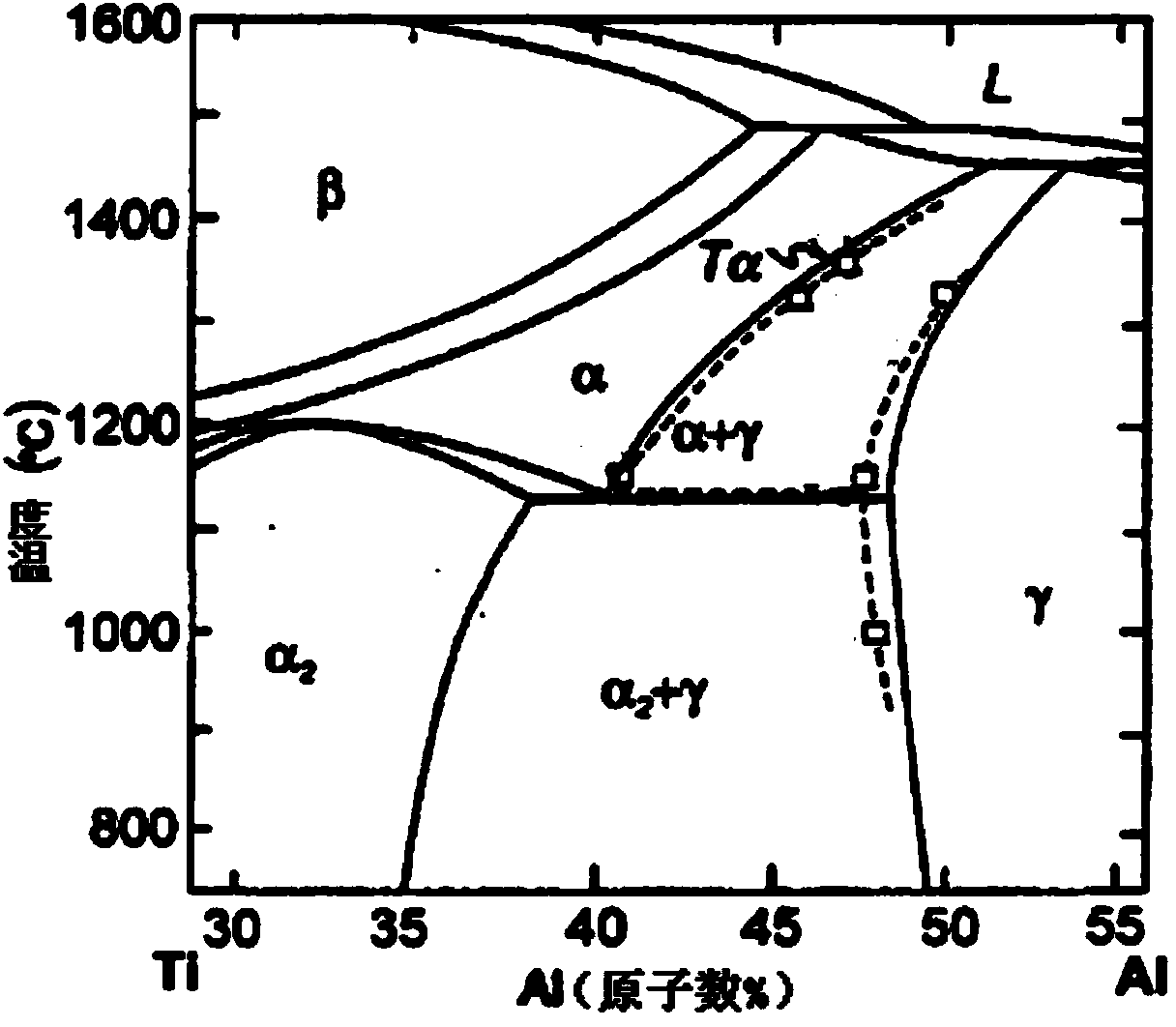

[0055] The α and β phases of powder metallurgy TiAl-based alloys (the composition of which is Ti-47Al-2Cr-2Nb-0.2W in atomic mole percent) with near-γ structure or γ structure to be heat treated are measured by differential thermal analysis (DSC) transition temperature T α is 1330°C;

[0056] The powder metallurgy TiAl-based alloy (its composition is Ti-47Al-2Cr-2Nb-0.2W in atomic mole percentage) prepared by hot isostatic pressing of powder with near γ structure or γ structure is cut into a size of 10× 10×10mm heat treatment sample, after coating a layer of glass powder on the surface of the sample, heat it to 1335 ° C for 15 minutes (take the rapid heating method of setting out at temperature), and then air cool to room temperature. The sample after heat treatment was ground, polished, corroded, and the microstructure of the alloy was observed. image 3 Shown is a relatively uniform, fine full-thickness sheet tissue. The average size of lamellar clusters is about 180 μm, ...

Embodiment 2

[0058] The α and β phases of powder metallurgy TiAl-based alloys (the composition of which is Ti-47Al-2Cr-2Nb-0.2W in atomic mole percent) with near-γ structure or γ structure to be heat treated are measured by differential thermal analysis (DSC) transition temperature T α is 1330°C;

[0059] The powder metallurgy TiAl-based alloy (its composition is Ti-47Al-2Cr-2Nb-0.2W in atomic mole percentage) prepared by hot isostatic pressing of powder with near γ structure or γ structure is cut into a size of 10× 10×10mm heat treatment sample, after coating a layer of glass powder on the surface of the sample, heat it to 1340 ° C for 15 minutes (take the rapid heating method of setting out at temperature), and then air cool the sample to room temperature. The samples after heat treatment were ground, polished and corroded, and the microstructure of the alloy was observed to obtain the following: Figure 5 Shown is a relatively uniform, fine full-thickness sheet tissue. The average si...

Embodiment 3

[0061] The α and β phases of powder metallurgy TiAl-based alloys (the composition of which is Ti-47Al-2Cr-2Nb-0.2W in atomic mole percent) with near-γ structure or γ structure to be heat treated are measured by differential thermal analysis (DSC) transition temperature T α is 1330°C;

[0062] The powder metallurgy TiAl-based alloy (its composition is Ti-47Al-2Cr-2Nb-0.2W in atomic mole percentage) prepared by hot isostatic pressing of powder with near γ structure or γ structure is cut into a size of 10× 10×10mm heat treatment sample, after coating a layer of glass powder on the surface of the sample, heat it to 1340 ° C for 25 minutes (take the rapid heating method of setting out at high temperature), then take the alloy out of the furnace, and air cool it to room temperature. The sample after heat treatment was ground, polished, corroded, and the microstructure of the alloy was observed. Image 6 Full-thickness slice tissue shown. The average size of laminar clusters is ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com