Efficient synthesizing jet-flow excitor

A technology of synthetic jet and exciter, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of low efficiency and insufficient power of synthetic jet, and achieve the improvement of the speed of the vortex ring, the output vorticity and the translation speed, and the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

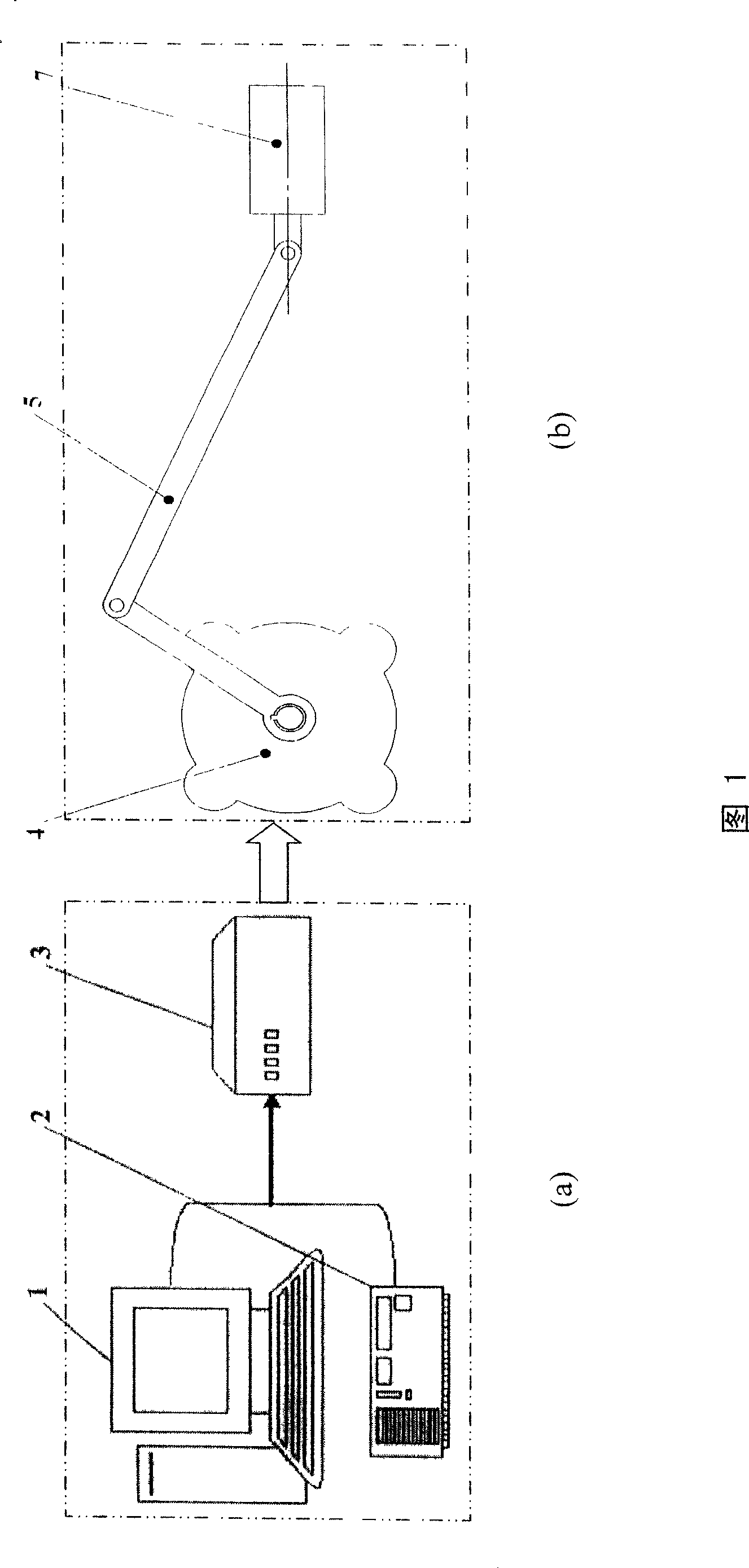

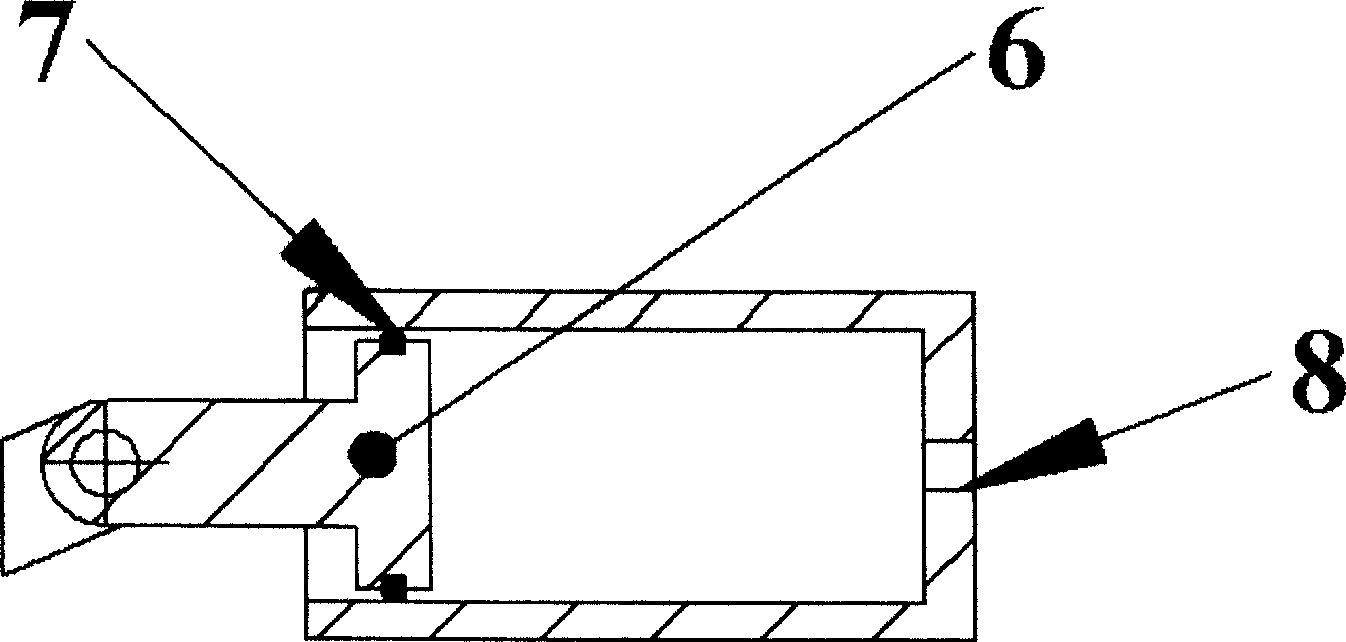

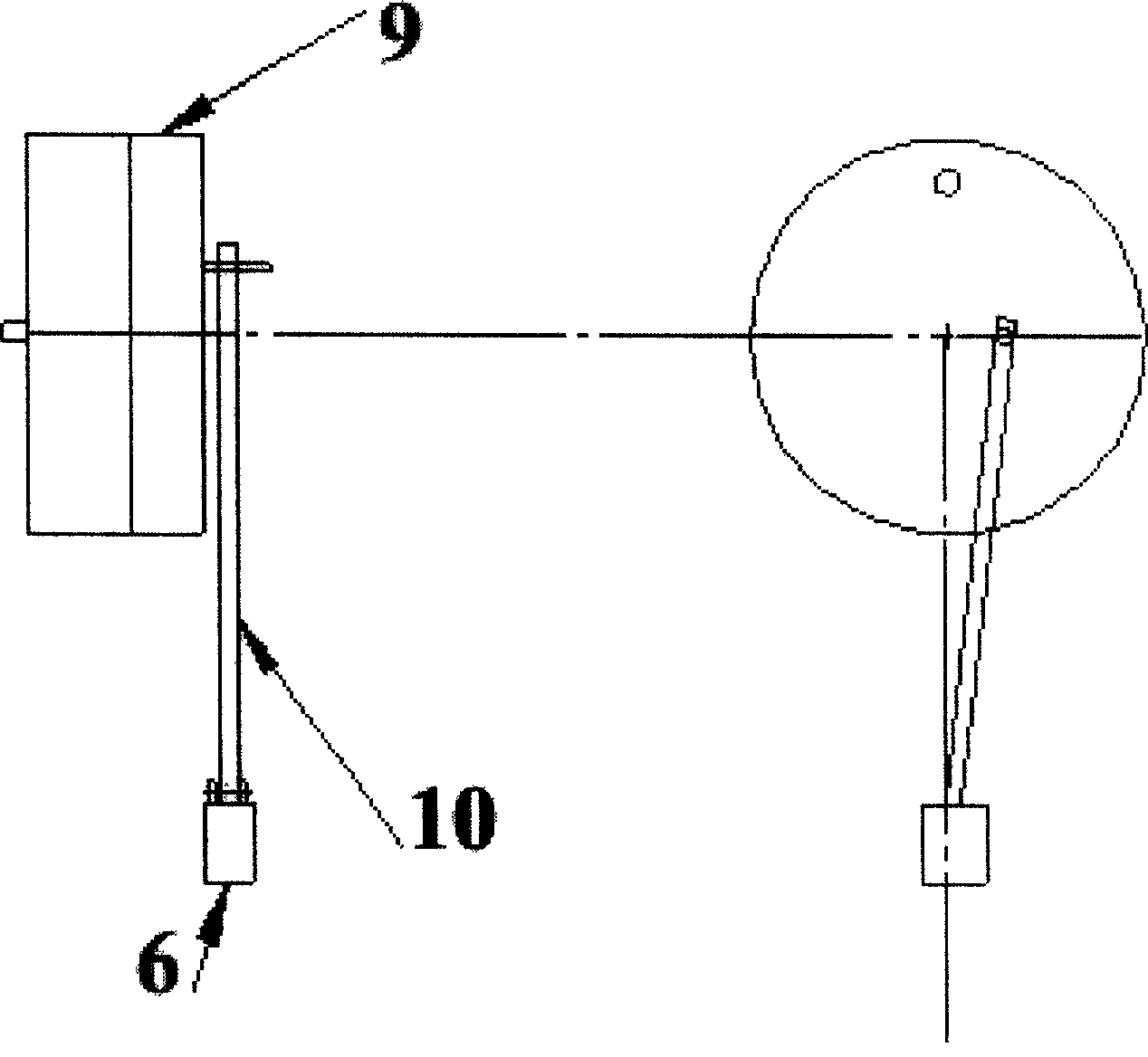

[0026] Please refer to Figure 1, figure 2 and image 3 As shown, the actuator consists of two parts: the control system and the execution system. The role of the control system is to generate a high-efficiency excitation signal to control and monitor the work of the exciter, which specifically includes a microcomputer 1, an A / D conversion card 2, and a programmable controller PLC3. The execution system receives instructions from the control system and works according to specified signals. It specifically includes a servo motor 4 , a centering crank mechanism 5 (including an eccentric disc 9 and a connecting rod 10 ), a vibrator 6 and a cavity 7 . The core of these two parts is the control system, and the core of the control system is the programmable controller PLC3, and the introduction of the programmable controller PLC3 becomes the core technology of the invention.

[0027] The specific connection mode of the high-efficiency synthetic jet exciter is as follows: the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com