Detector for boron containing lean oxygen propellant heat value

A test device and propellant technology, which is applied in the field of calorific value measurement devices, can solve problems such as insufficient combustion of boron-containing oxygen-poor propellants, and achieve the effects of simple structure, wide application prospects, and stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

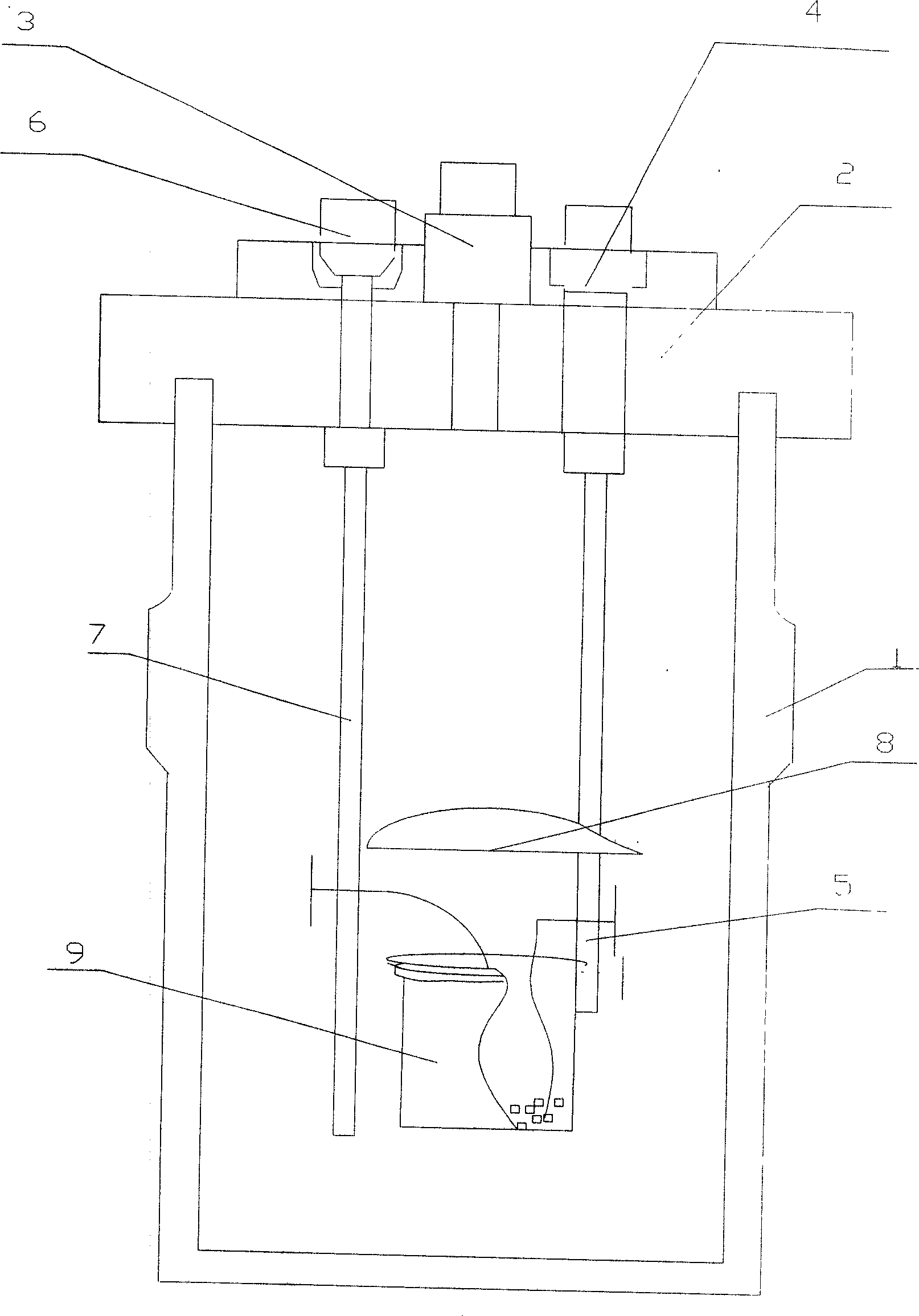

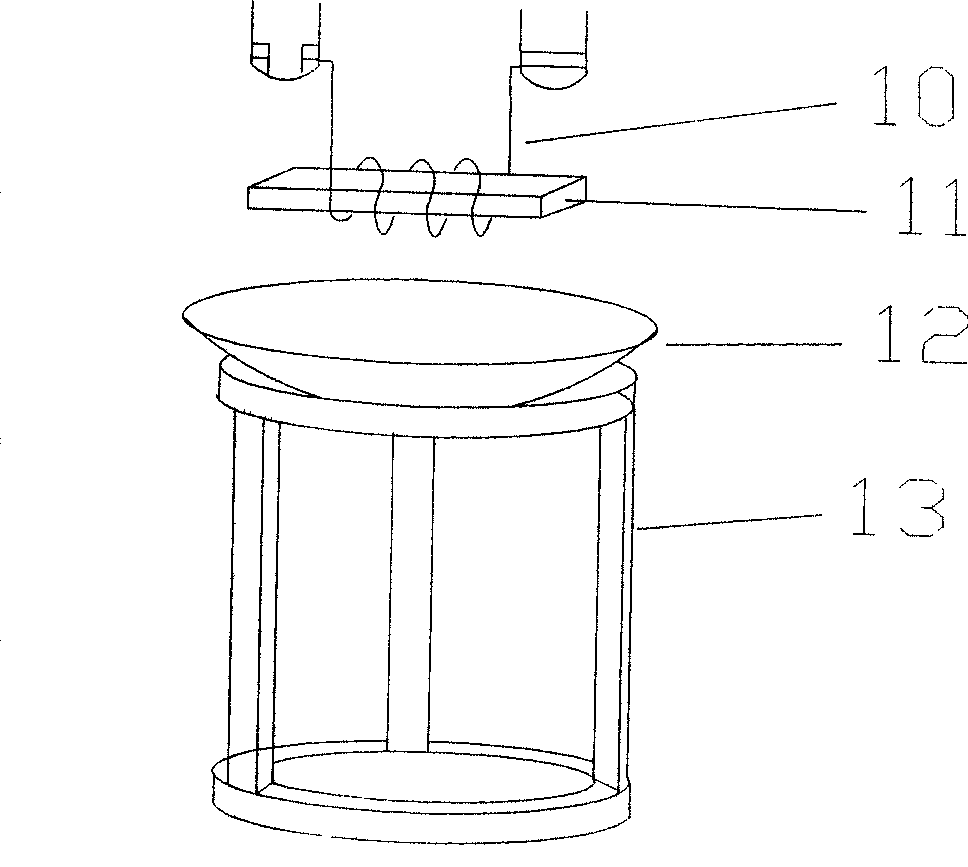

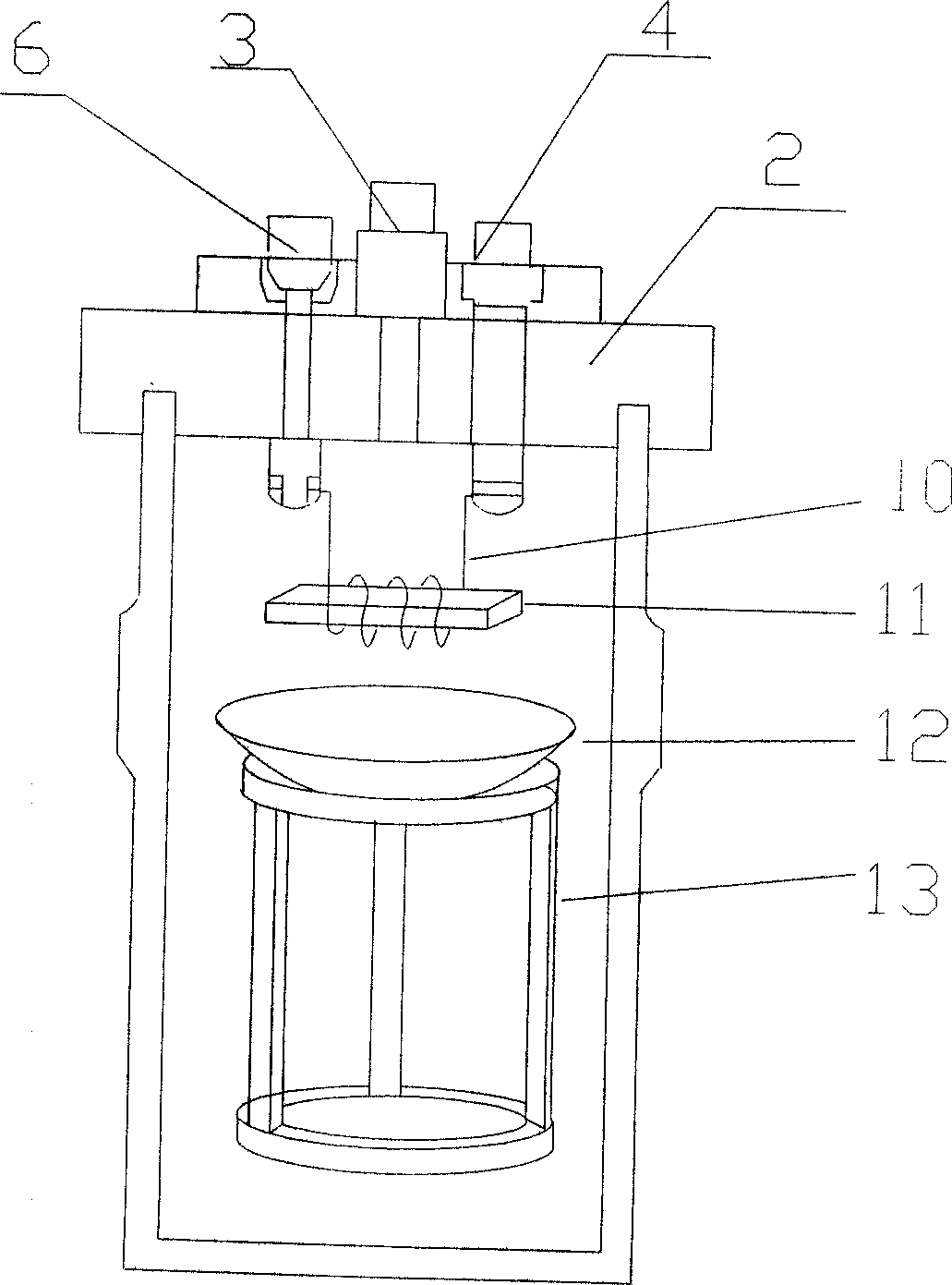

[0016] Example 1: the present invention has adopted a kind of new calorific value testing device, comprises projectile body 1, and projectile body is the thick-walled cylinder that volume is 300 milliliters; There is deflation valve 3, electrode 4, inflation valve 6 on projectile 2, The electrode 4 is insulated from the warhead 2, and the ignition wire 10 is connected between the inflation valve 6 and the electrode 4. The ignition wire is a nickel-chromium alloy wire with a diameter of 0.1 mm and a calorific value of 3.2 J / cm. Sample 11 is 1.0 g of boron-containing oxygen-poor propellant, which is wound and suspended in the oxygen bomb by ignition wire 10. The distance between the sample and the crucible is 15 mm. The crucible 12 is placed on the crucible frame 13. / carbon composite material, the crucible frame 13 is the upper and lower ring crucible supports of heat-resistant and anti-corrosion nickel-chromium-molybdenum alloy steel, placed on the bottom of the oxygen bomb to...

example 2

[0017] Example 2: the present invention comprises projectile body 1, and projectile body is the thick-walled cylinder that volume is 300 milliliters; There is deflation valve 3, electrode 4, inflation valve 6 on bullet 2, electrode 4 and bullet 2 insulation, inflation valve 6 and An ignition wire 10 is connected between the electrodes 4, and the ignition wire is a nickel-chromium alloy wire with a diameter of 0.1 mm and a calorific value of 3.2 J / cm. Sample 11 is 0.5g of boron-containing oxygen-poor propellant, which is wound and suspended in the oxygen bomb by the ignition wire 10, and the distance from the bottom of the oxygen bomb is 60mm, and the combustion accelerant placed at the bottom of the oxygen bomb is double lead-2 propellant, and its The diameter is 50mm and the height is 1.5mm. The calorific value of the sample was tested with an oxygen bomb without a crucible and a crucible support, and the calorific value of the sample was measured to be 29.89MJ / Kg, and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com