Base plate with buried passive element and its producing method

A technology for passive components and packaging substrates, which is applied in the manufacture of semiconductor/solid-state devices, assembling printed circuits with electrical components, and printed circuits connecting non-printed electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

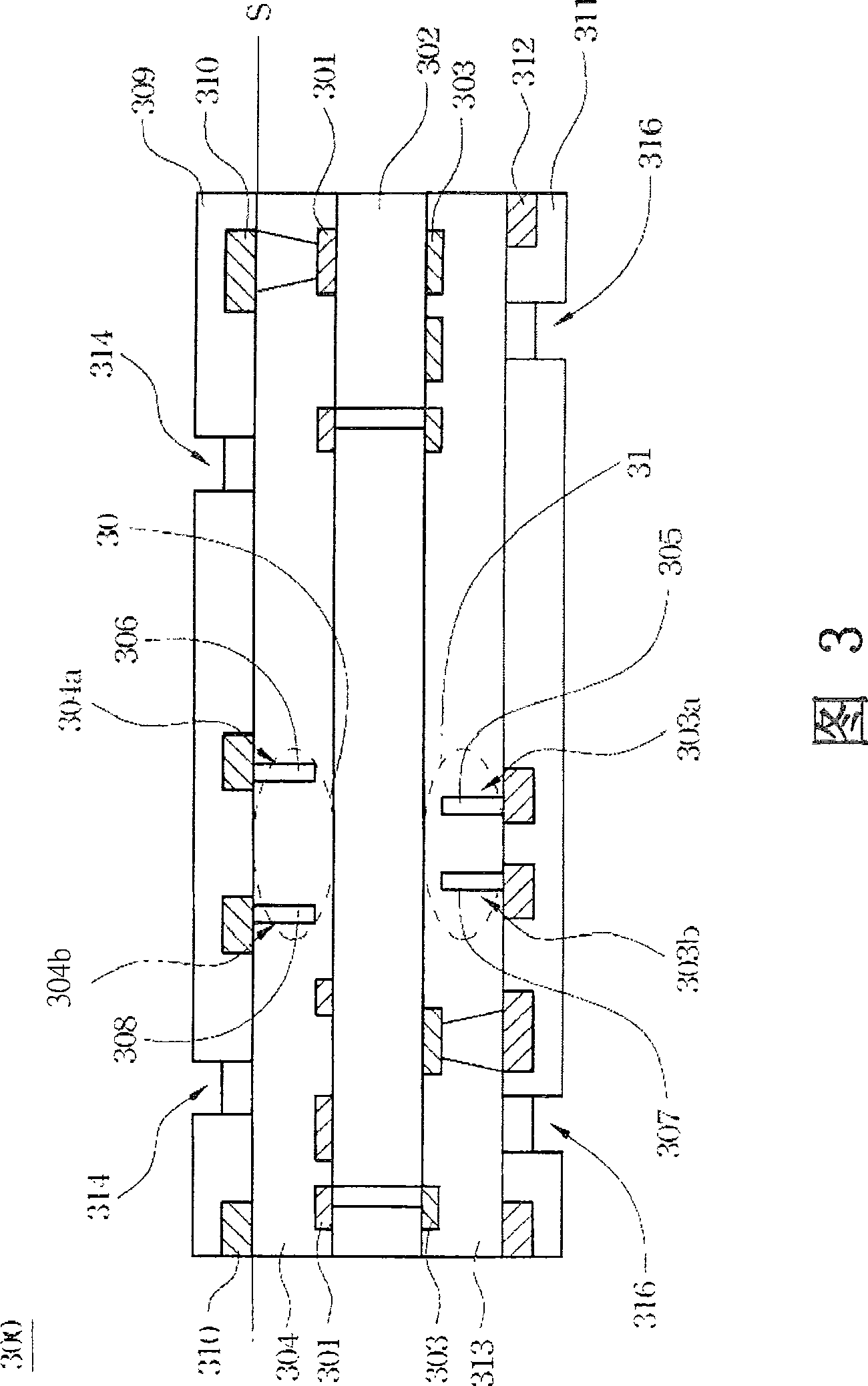

[0017] Relevant detailed description and technical contents of the present invention are as follows now in conjunction with the accompanying drawings:

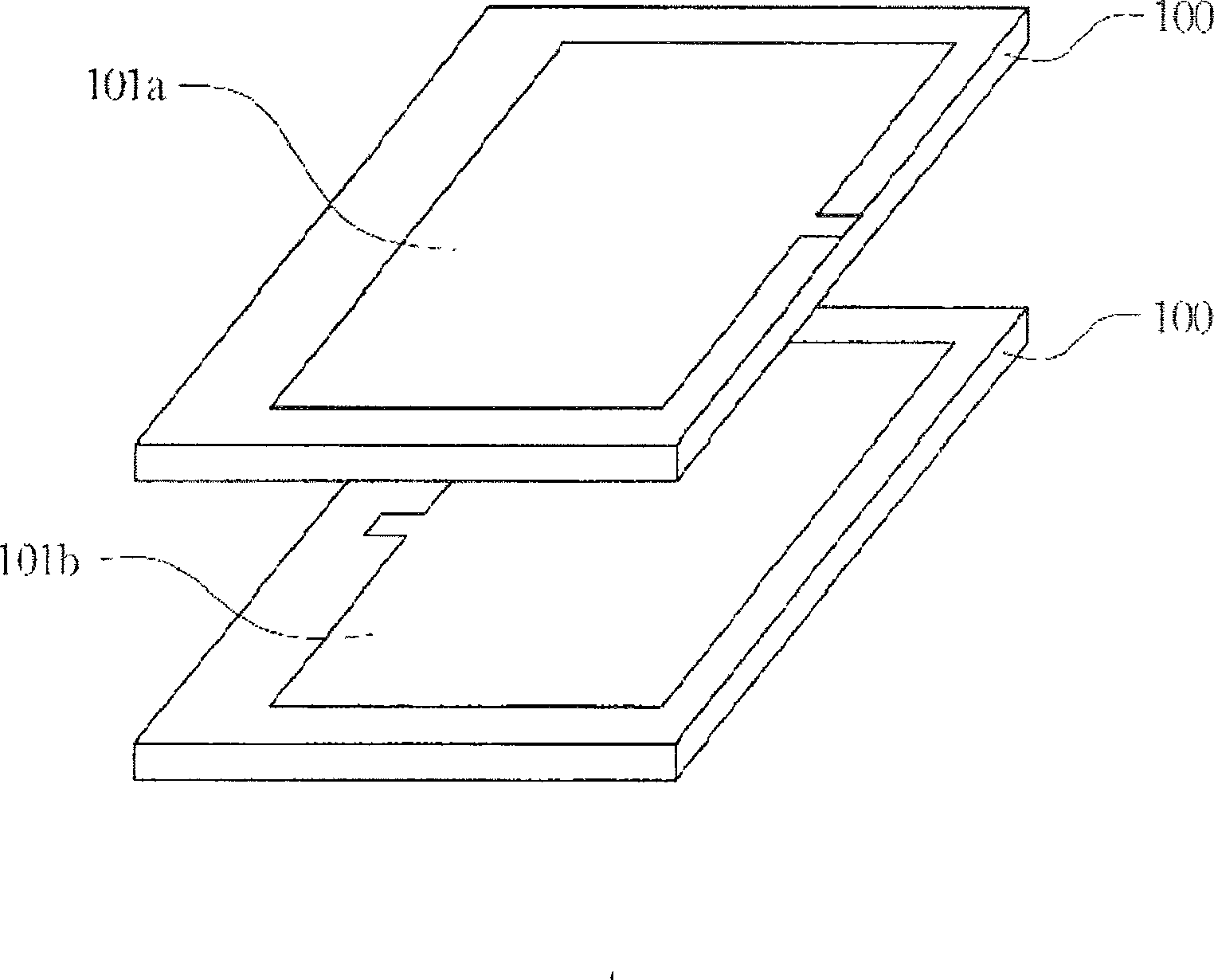

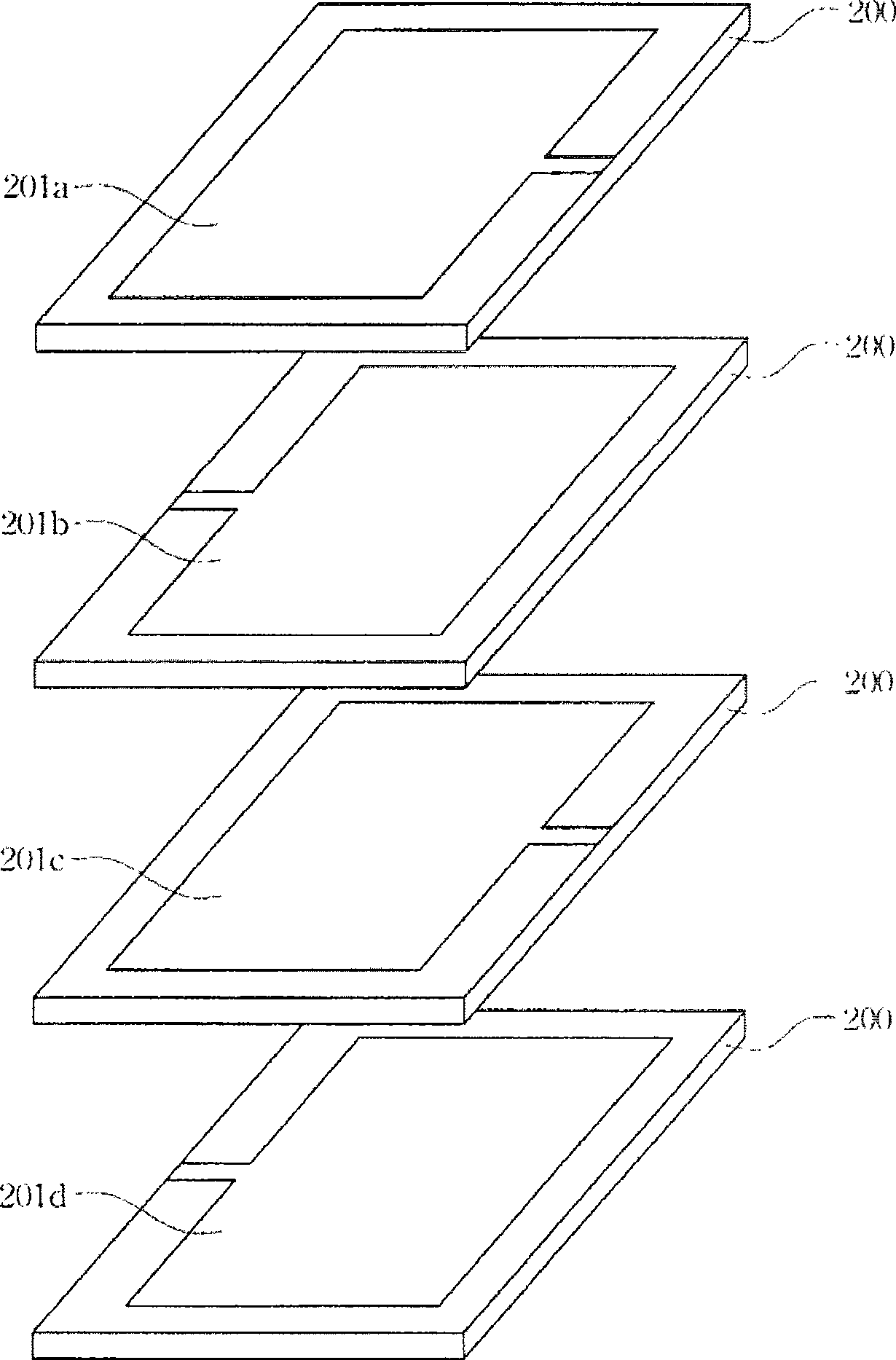

[0018] An embodiment of the present invention is to provide a die-carrying packaging substrate with embedded passive elements. In order to make the above and other purposes, features, and advantages of the present invention more comprehensible, a die-carrying packaging substrate 300 embedded with an embedded capacitor 30 is taken as a preferred embodiment for illustration.

[0019] FIG. 3 is a cross-sectional view of a longitudinal structure of a die-carrying packaging substrate 300 embedded with an embedded capacitive element 30 according to a preferred embodiment of the present invention. The package substrate 300 for carrying dies includes: a lower lamination layer 313 , an interlayer circuit board 302 with a first conductive circuit 301 , a dielectric layer 304 , a first electrode 306 , a second electrode 308 and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com