Forming structure for honeycomb paper board, paper core

A technology of forming structure and honeycomb paperboard, applied in the field of paper core forming structure and weaving honeycomb paperboard, can solve the problems of unacceptable, complicated and high investment cost for small and medium-sized enterprises, saving space, low manufacturing cost, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

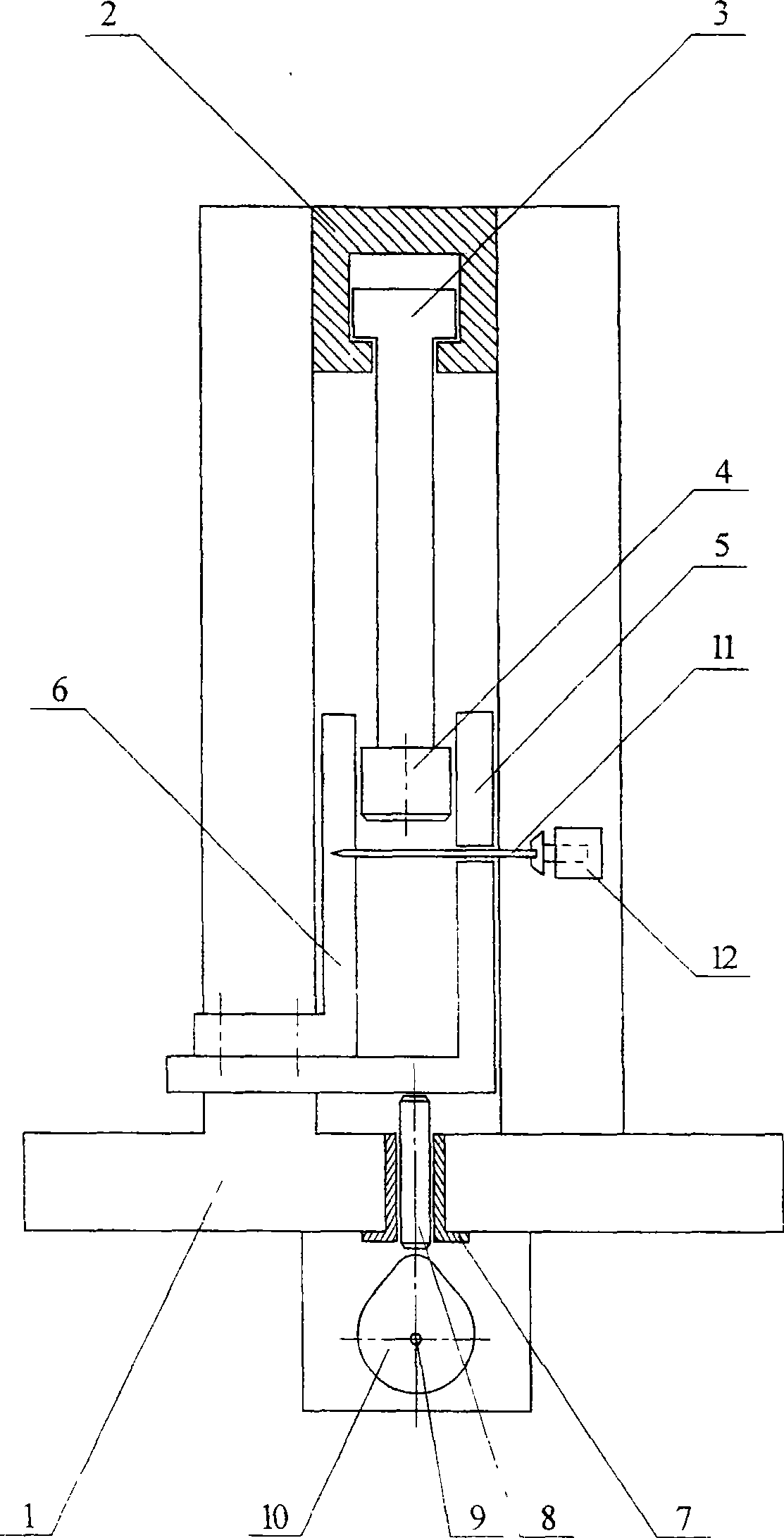

[0011] The present invention mainly consists of frame 1, guide groove 2, shuttle plate 3, die head 4, first forming clamping die 5, second forming clamping die 6, conduit 7, ejector rod 8, camshaft 9, cam 10, positioning pin 11. Absorb iron 12 and other components.

[0012] The present invention adopts guide groove 2 to be installed on the frame 1 by screws, the first forming clamping die 5 is installed on the frame 1 through the chute, and the second forming clamping die 6 is installed on the first forming clamping die 5 by screws, which can Make adjustments to adapt to the molding of honeycomb paper cores of different thicknesses. The camshaft 9 is installed on the frame 1 through bearings, the cam 10 is installed on the camshaft 9, the conduit 7 is installed on the frame 1 through screws, the ejector rod 8 is installed in the conduit 7, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com