Method for preparation of quilt and device for actualizing said method

A manufacturing method and quilt technology, applied in the field of quilt manufacturing, can solve problems such as difficulty in ensuring quilt quality and low production efficiency, and achieve the effects of reduced labor intensity, improved production efficiency, and low skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

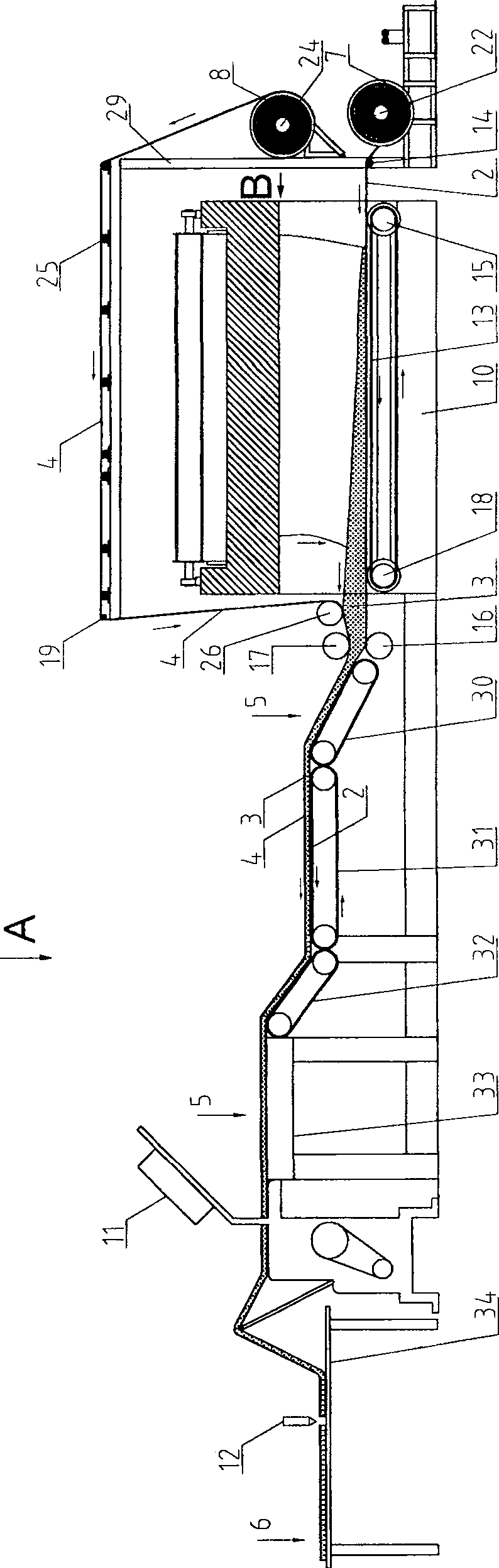

[0056] Such as Figure 1 to Figure 3 Shown, present embodiment is a kind of manufacturing method of quilt, and this method comprises the following steps successively:

[0057] a. Carding:

[0058] The whole bundle of synthetic hollow fiber battings is opened by an opener to loosen the bundled fibers, and then the opened cotton batts are quantitatively and evenly input into the carding machine 9 by an automatic cotton feeder. Carding machine 9 continuously outputs strip-shaped thin cotton layer 1 with fixed width and thickness after carding the cotton wool.

[0059] b. Spread cotton on the lower fabric:

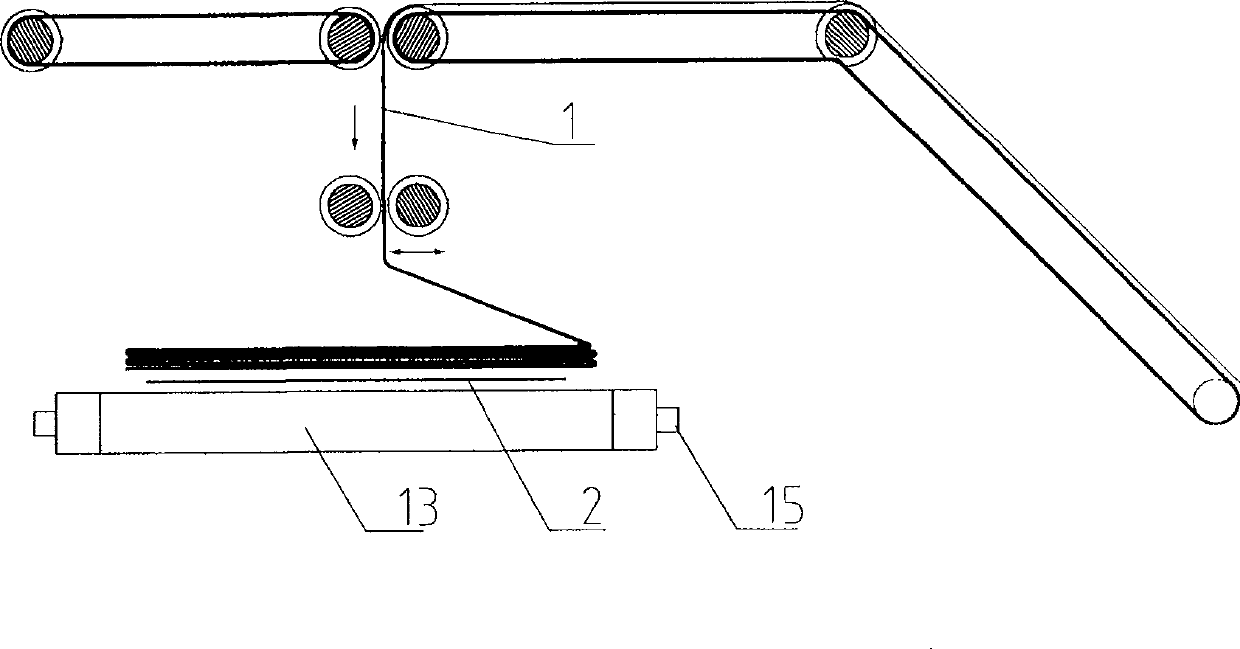

[0060] The lower fabric 2 with a width of 2 meters is gradually exported from the lower fabric roll 7, and the output lower fabric 2 is flattened to both sides, and the flattened strip-shaped lower fabric 2 is moved along the vertical direction on the longitudinal conveyor belt 13 of the plane forming machine 10. uniform motion. The thin cotton layer 1 output in step a fal...

Embodiment 2

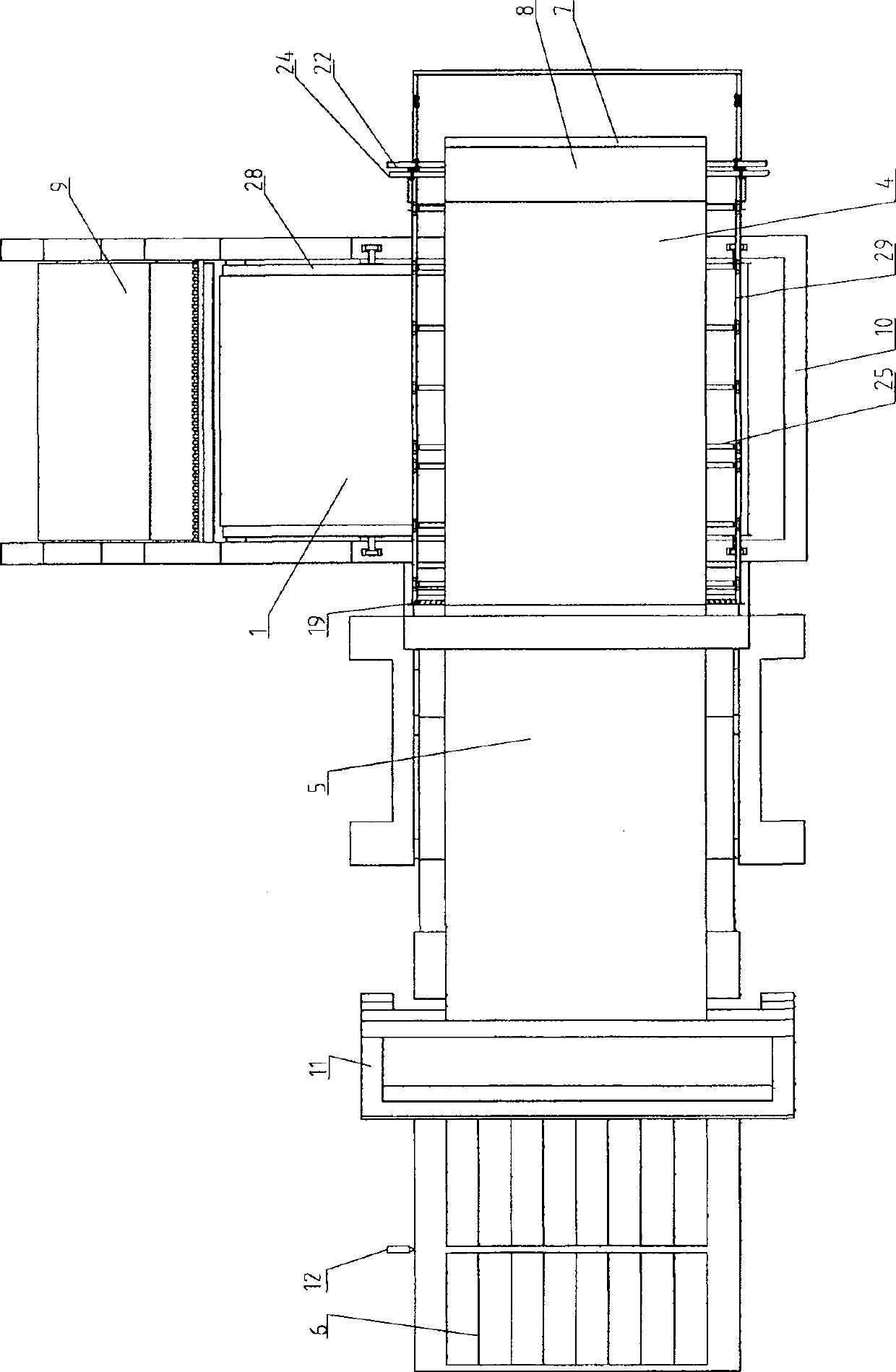

[0070] Such as Figure 1 to Figure 3 and Figure 6 to Figure 11 As shown, the present embodiment is a quilt manufacturing device for completing the method of Embodiment 1, and the device includes a carding machine 9 , a plane forming machine 10 , a quilting machine 11 and a cutting machine 12 . Carding machine 9 adopts SWA-D60 type single doffer carding machine made in Taiwan, China. Plane forming machine 10 adopts SWA-C160 type plane forming machine made in Taiwan, China. Quilting machine 11 is on the common KW-118A type quilting machine, and its driving motor is equipped with a frequency conversion speed regulating device, and parts such as a coiling machine are omitted. Cutting machine 12 adopts CZD-B11 type cutting machine.

[0071] The output end of the carding machine 9 is connected with the input end of the plane forming machine 10 , and the output end of the carding machine 9 is aligned with the transverse conveyor belt 28 of the plane forming machine 10 . Support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com