Improved fuel delivery system

A technology of fuel delivery and fuel, which is applied in the direction of turbine/propulsion fuel delivery system, charging system, fuel valve of turbine/propulsion device, etc. It can solve the problems of reducing components, increasing the number of components, etc., and achieving the effect of improving capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

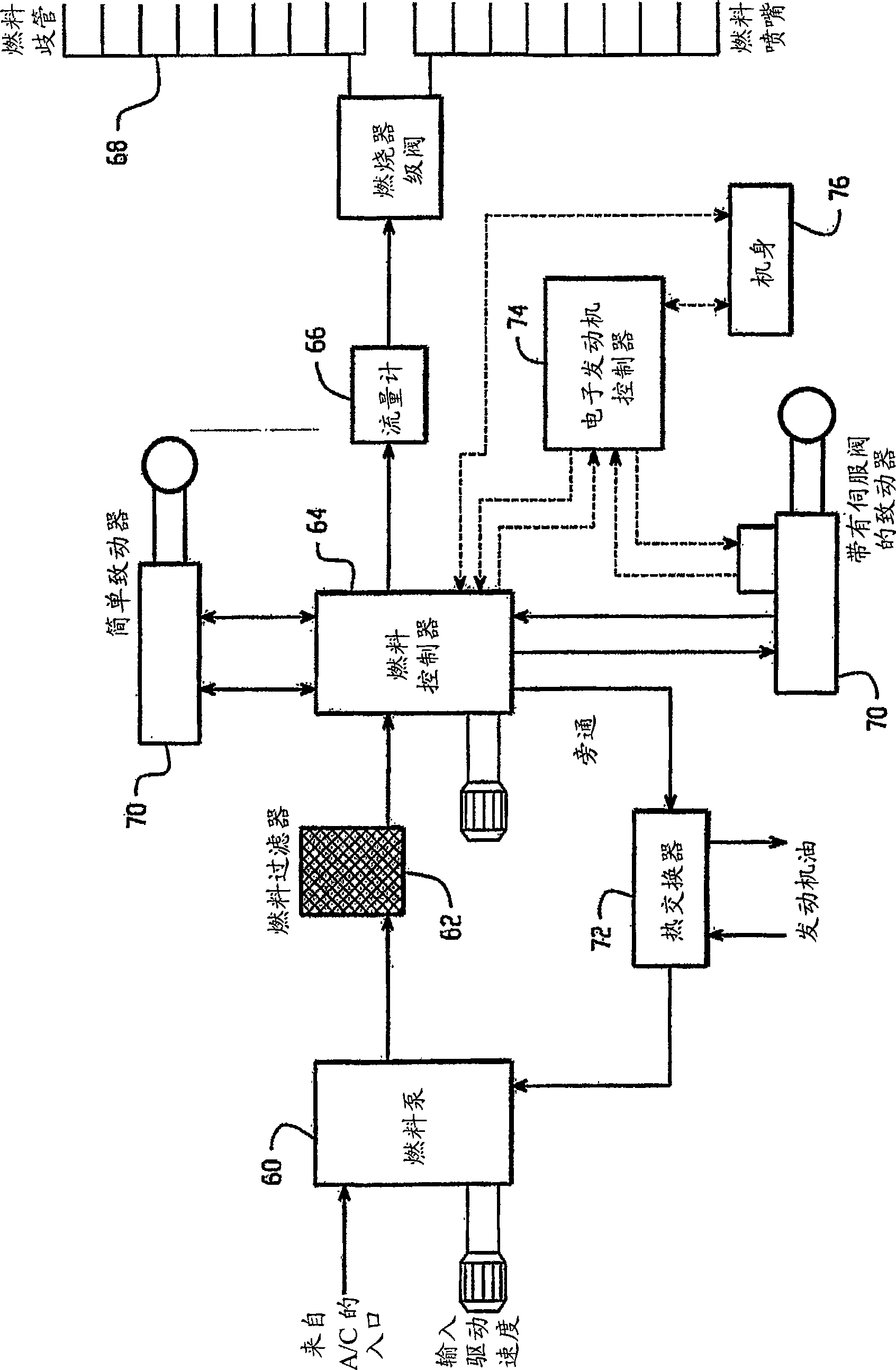

[0026] By means of other background technologies of the present invention, figure 1 A high level and more detailed conventional engine fuel system is schematically shown. Since such systems are generally known to those skilled in the art, only a brief overview of selected parts is provided to understand the features and benefits offered by the present invention.

[0027] as in figure 1 As shown schematically in the high level diagram in , the prior art system includes a fuel pump 60 for supplying fuel through a filter 62 to a fuel controller 64 . The pump is a displacement device that delivers a metered flow of fuel to the fuel controller based on engine speed. The delivered portion of the fuel flow is metered and delivered to an engine combustion chamber (not shown). The metered portion of the fuel flow is supplied to the combustion chambers via fuel flow meter 66 before reaching the fuel distribution manifold and fuel nozzles 68 . Another portion of the fuel flow deliver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com