Assembled piston for an internal combustion engine

A technology of internal combustion engine and piston, which is applied in the field of internal combustion engine piston assembly, which can solve the problems of large piston compression height, blind hole space and screw head space, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

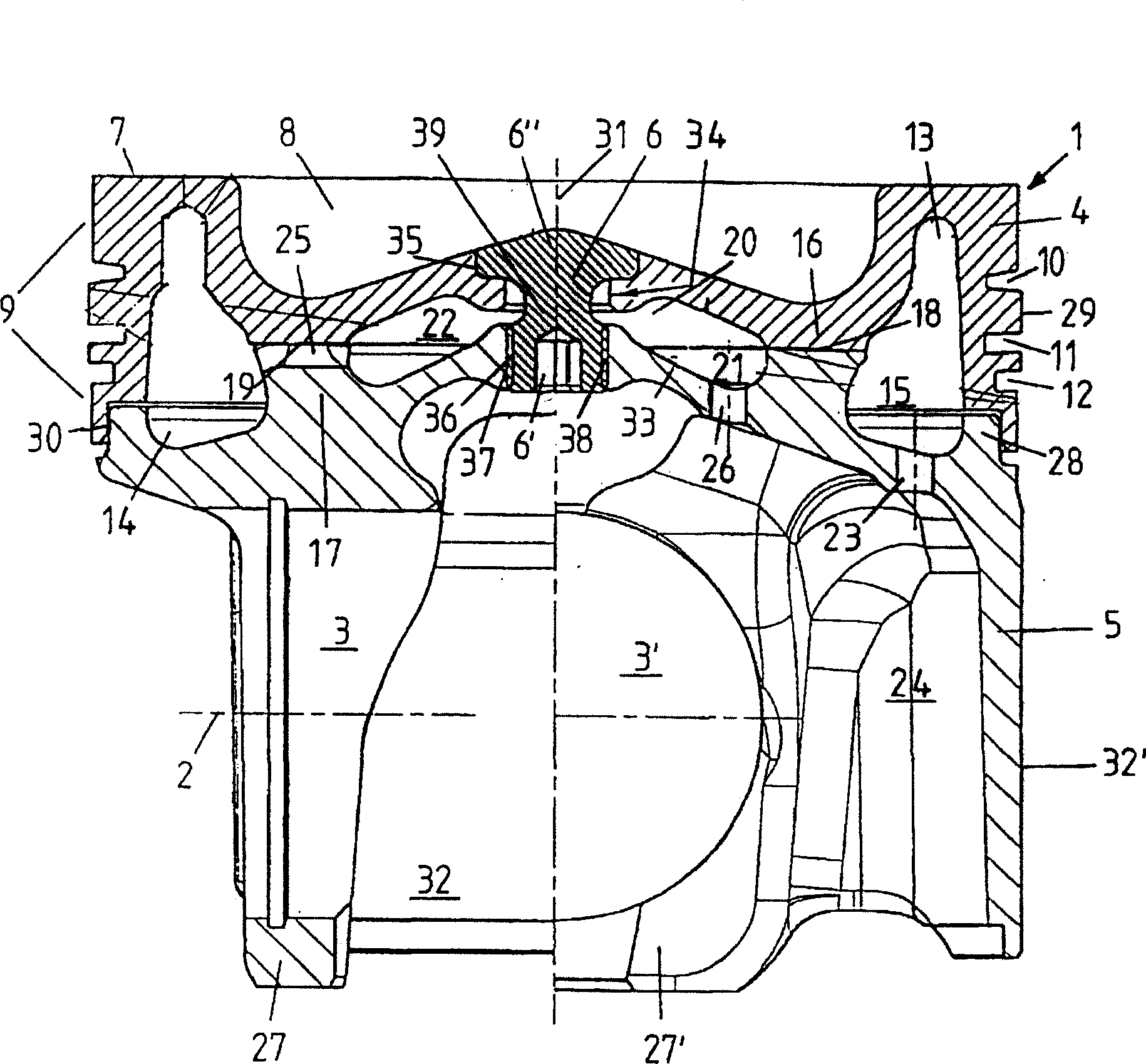

[0049] The figures show the assembled piston 1 in a cross-sectional view, the left half of which represents a cross-section of the piston 1 along the longitudinal axis 2 of the piston pin housing bore 3, while the right half represents a cross-section with the left half A 90-degree cross-sectional view of the piston. The piston 1 consists of an upper part 4 and a lower part 5, which are connected to each other by means of a concentrically arranged threaded pin 6 comprising a hexagon socket 6' and a flat head 6" on the side facing away from the hexagon socket, The connection of the upper part and the lower part is such that the head 6' of the threaded pin 6 is located inside the piston. Here, the head 6" of the threaded pin 6 has a larger radial diameter than the external thread 38. Between the head 6 ″ and the external thread 38 the threaded pin 6 has an expansion region 39 with a smaller radial diameter than the external thread 38 .

[0050] The upper part 4 and the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com