Screw teeth scrubbing plate set with cooling function

A rubbing board and tooth board technology, applied in the field of screw rubbing board structure, can solve the problems of poor heat dissipation, heat accumulation, etc., achieve a good quality level, reduce heat energy accumulation, and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

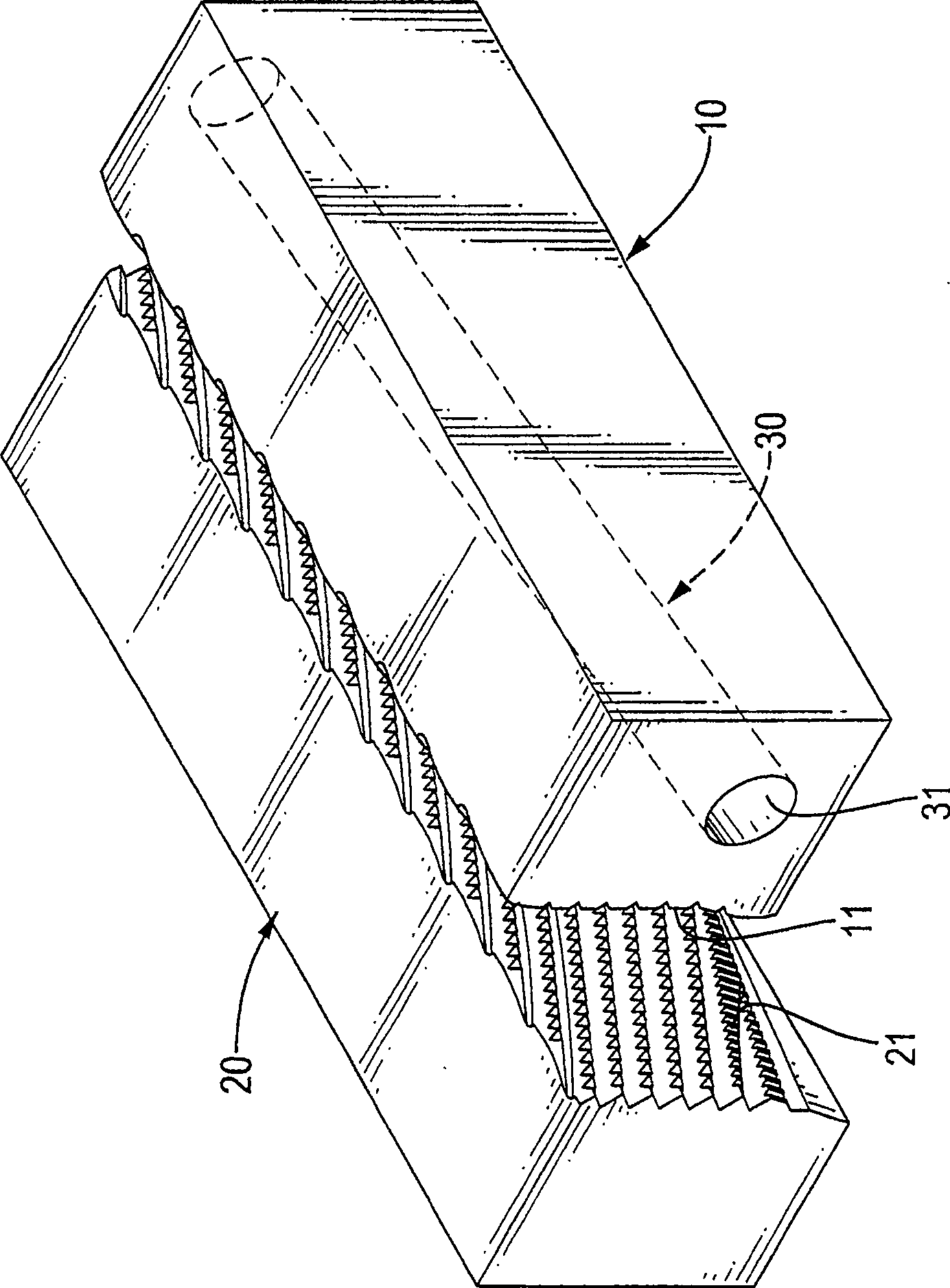

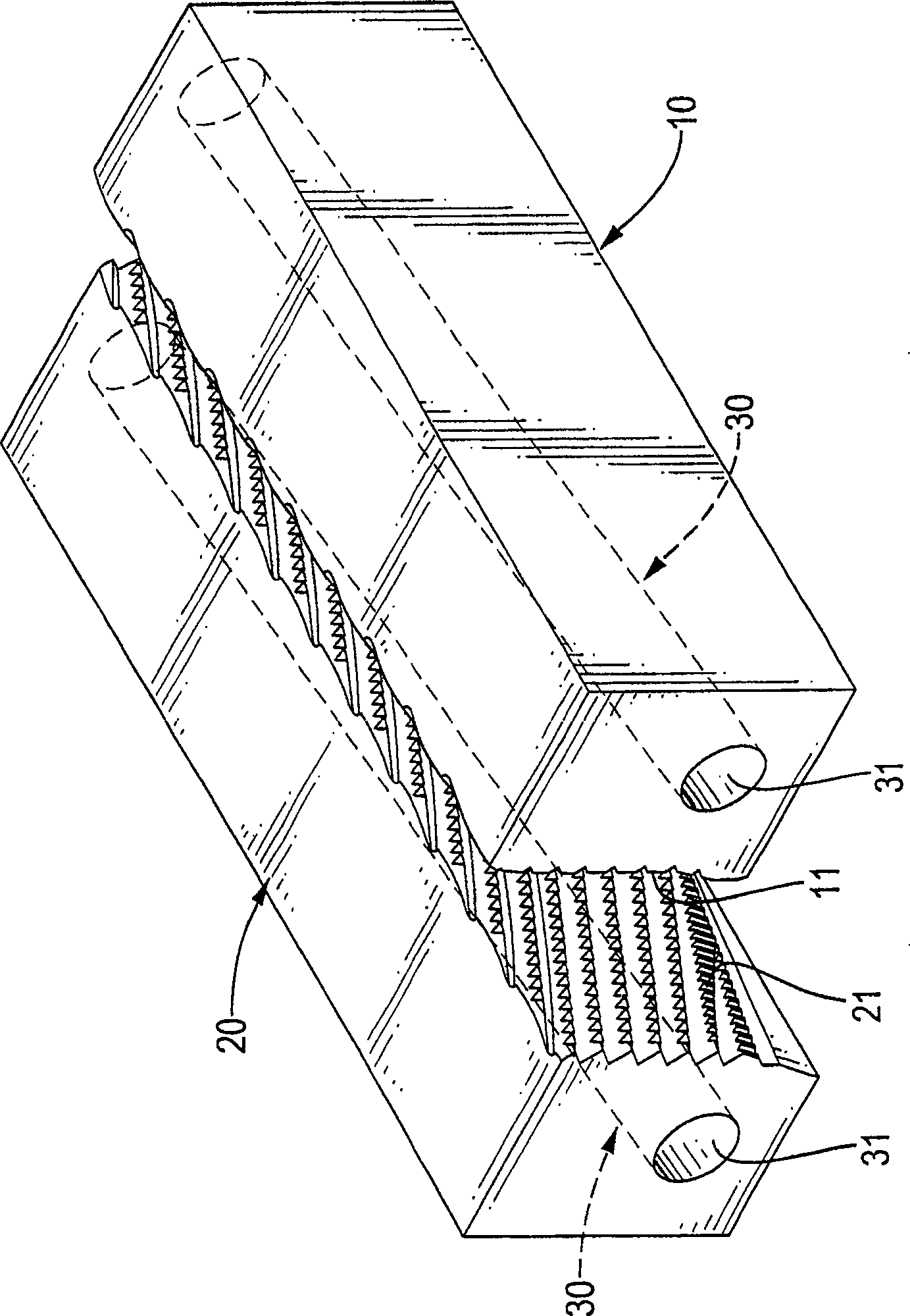

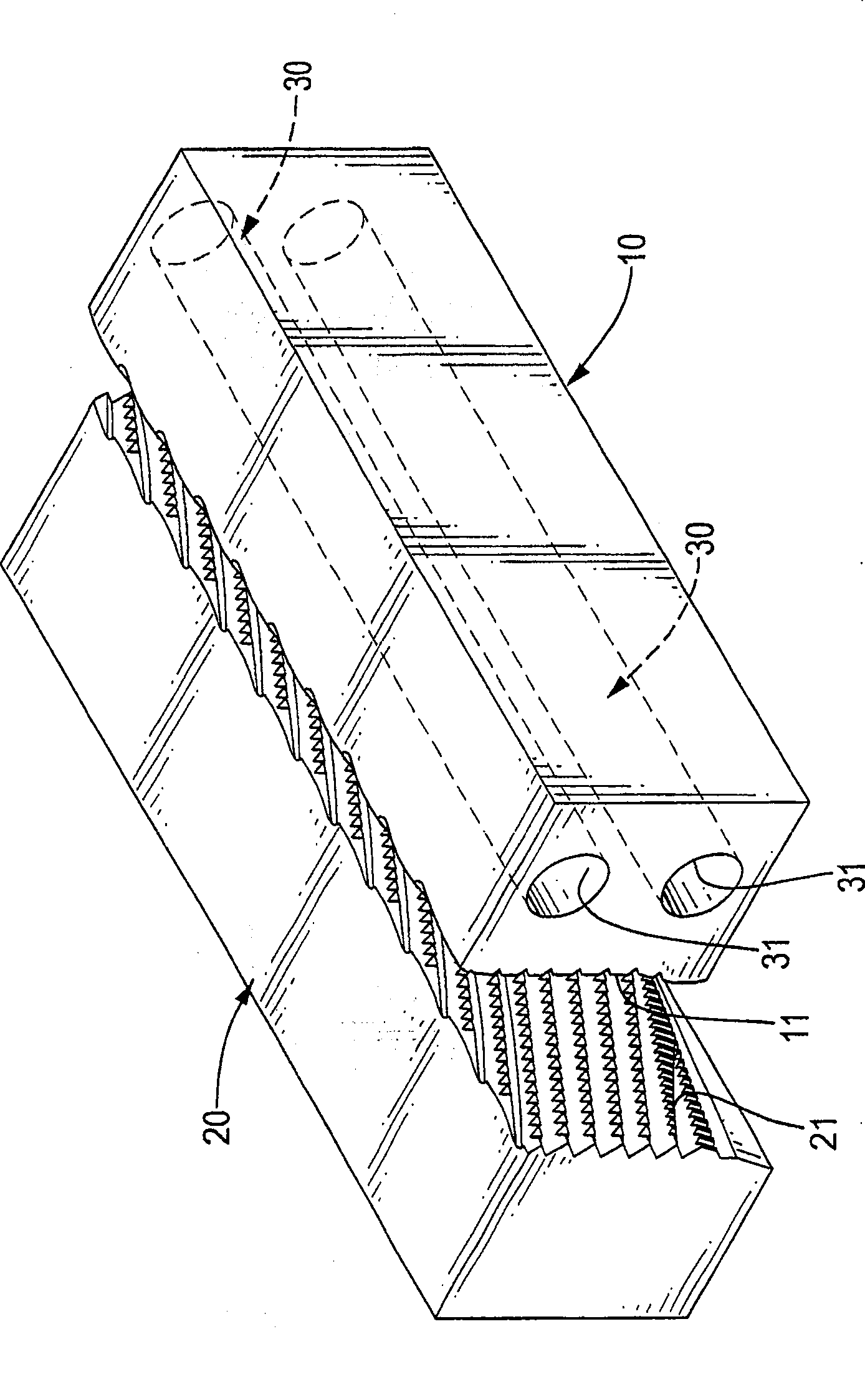

[0021] like figure 1 As shown, the screw rubbing plate group with cooling function of the present invention includes a fixed tooth plate 10 and a movable tooth plate 20, wherein the fixed tooth plate 10 is a long block-shaped plate body with a rubbing plate on one side. Tooth action surface 11, the movable tooth plate 20 is also a strip-shaped plate body, and is arranged parallel to the side of the fixed tooth plate 10 with the tooth rubbing action surface 11, and the mobile tooth plate 20 is adjacent to the fixed tooth A teeth rubbing action surface 21 is provided on the side of the plate 10 . In addition, the screw rubbing die set of the present invention also selects one or both of the fixed die 10 and the movable die 20 to set a refrigerant passage 30 for connecting the cooling cycle system so that the fluid refrigerant flows through the refrigerant passage 30 Medium circulation provides cooling.

[0022] The design of the above-mentioned refrigerant channel 30 includes ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap