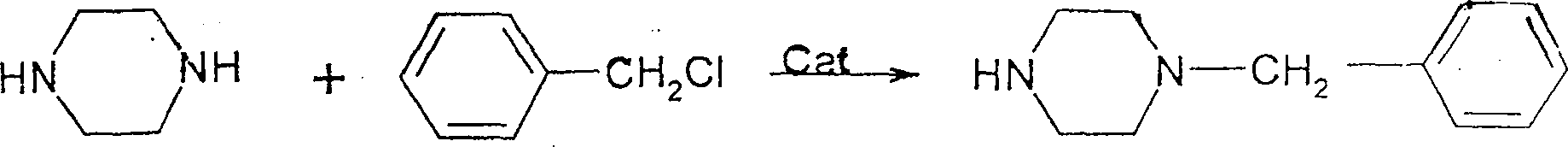

Process for preparing N-benzyl piperazine

A technology of benzylpiperazine and piperazine, which is applied in the field of preparation of N-benzylpiperazine, can solve the problems of low yield, complicated operation and low product purity, and achieves a high yield, simple operation and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0019] In a 500ml reaction bottle, drop 25.8g (0.3mol) of piperazine and 100ml of solvent anhydrous methanol, stir and dissolve, then drop into the catalyst aniline hydrochloride, heat up to 50 degrees, drop 38g (0.3mol) of benzyl chloride, about Add dropwise in half an hour. Keep the temperature at 50°C for 3 hours, cool to normal temperature, reduce the pressure to 15mmhg, and evaporate to remove the solvent methanol. Then add NaOH solution, adjust the pH value to 13, and extract twice with ethyl acetate, each with 50 ml of ethyl acetate. Distill the extract under normal pressure, reduce the pressure to 2.5 mmhg, and collect fractions at 120—124°C by distillation to finally obtain 50.5 g of the target product, N-benzylpiperazine, with a yield of 95.5% and a purity of 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com