Double-side hot-melt adhesive film and process for making same

A technology of hot-melt adhesive film and preparation process, which is applied in the direction of adhesives, film/sheet adhesives, etc., which can solve the problems of waste of human resources in mounting time, affect the effect and quality of mounting, and uneven mounting works, etc., and achieve simplification Mounting operation, short mounting time, less wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

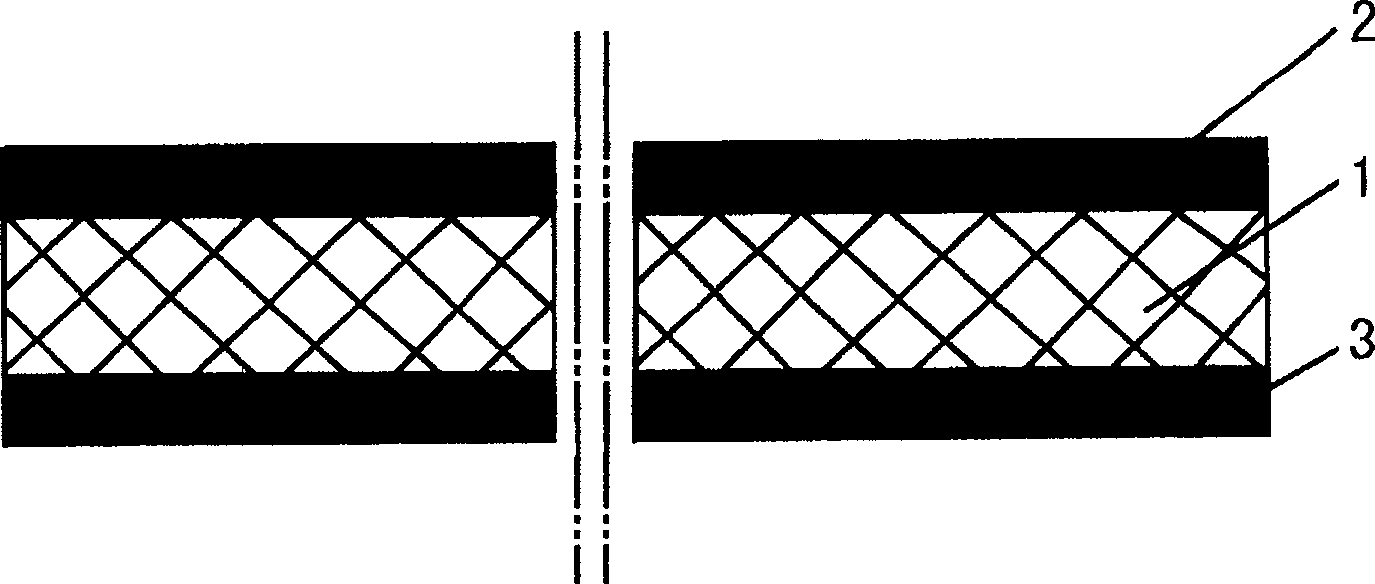

[0015] The structure of the present invention and its preparation process will be further described in detail below in conjunction with the accompanying drawings.

[0016] The double-sided hot-melt adhesive film has the following structure: the two sides of the paper layer 1 are coated with a hot-melt adhesive layer 1 2 and a hot-melt adhesive layer 2 3 . The raw material used for the hot-melt adhesive layer 1 2 and the hot-melt adhesive layer 2 3 is ethylene-vinyl acetate copolymer resin, namely EVA28.150. The thickness of the paper layer 1 is 0.001mm-0.6mm. The thickness of the hot melt adhesive layer 1 2 and the hot melt adhesive layer 2 3 is 0.001-0.1 mm.

[0017] The preparation process of the above-mentioned double-sided hot-melt adhesive film includes the following process steps: heating the used hot-melt adhesive ethylene-vinyl acetate copolymer resin, namely French EVA28.150, to 120°C or 140°C or 160°C, and heating the heated Put the hot melt adhesive into the hot g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com