Reduced bidirectional strength closed high temperature ball valve

A high temperature, ball valve technology, used in valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as inconvenience for widespread adoption, inconvenience for re-installation of valve actuators, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

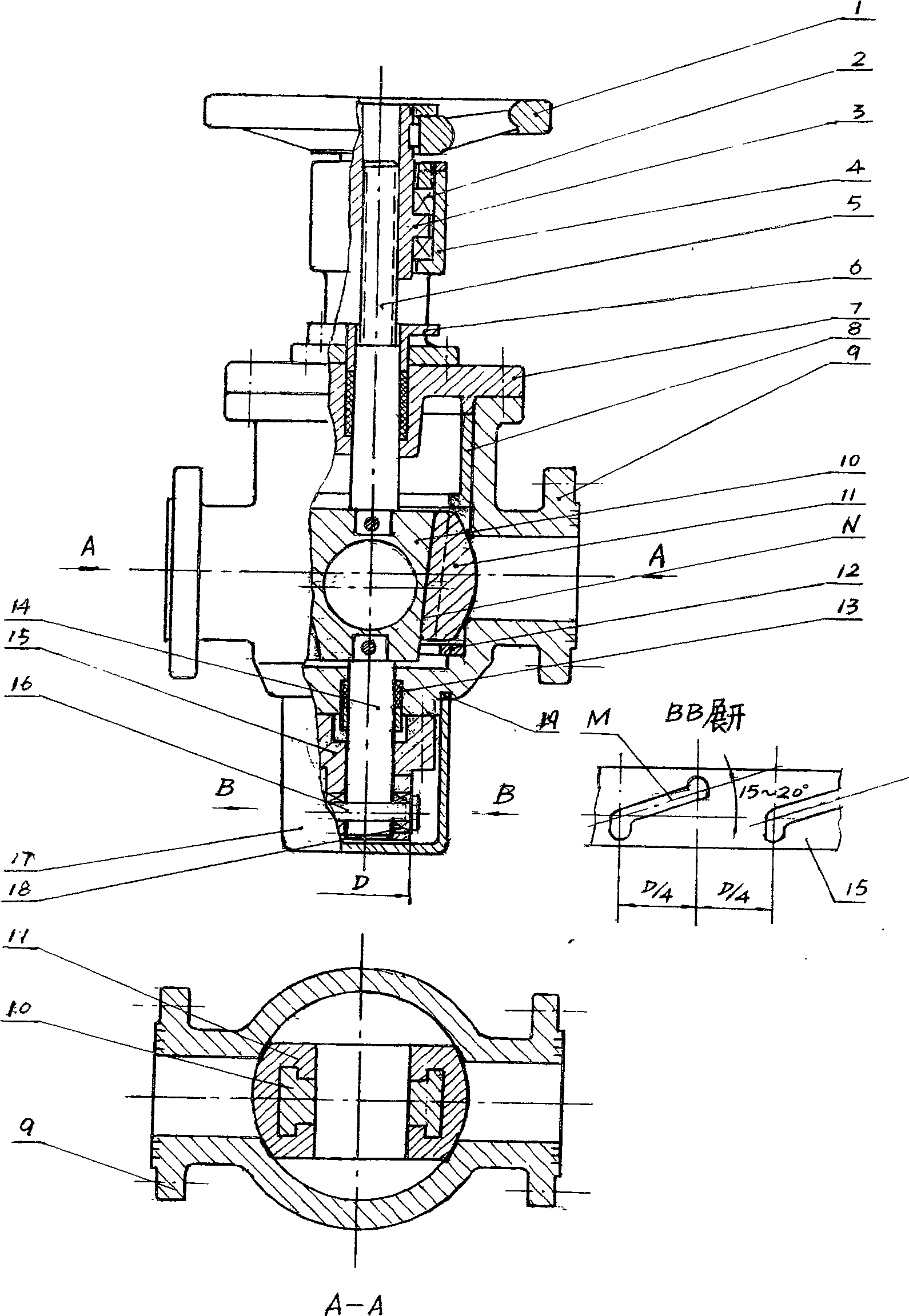

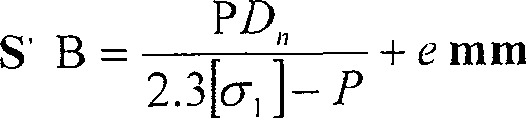

[0019] In the following, specific examples will be combined to describe the implementation in detail. as attached figure 1 In the structure shown, the flange hole diameter of the valve body 9 is φ50, the applicable nominal pressure is 6.3Mpa, the airtight test is 0.6Mpa, the applicable temperature is 400°-450°C, and it is suitable for transporting sulfur-containing medium.

[0020] According to the structure shown in the figure, when the handwheel 1 is turned, the upper valve stem 5 fixed on the upper side of the three components of the sphere is driven by the thread to displace through the rotation of the copper nut 3 supported in the bearing shell 4 . Meanwhile, cross pin and roller assembly 16,18 are arranged on lower valve stem 14, roll in the groove of program sleeve 15. According to the program setting, it can be used as a three-stage working program opening and closing valve with a straight line up and down and a 90° rotation in the middle.

[0021] The three-ball ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com