Liquid fermentation tank inoculation device of obligate anaerobes, and inoculation method

A fermenter and inoculation needle technology, applied in the field of microbial fermentation, can solve the problems of lack of anaerobic fermenter inoculation device, sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

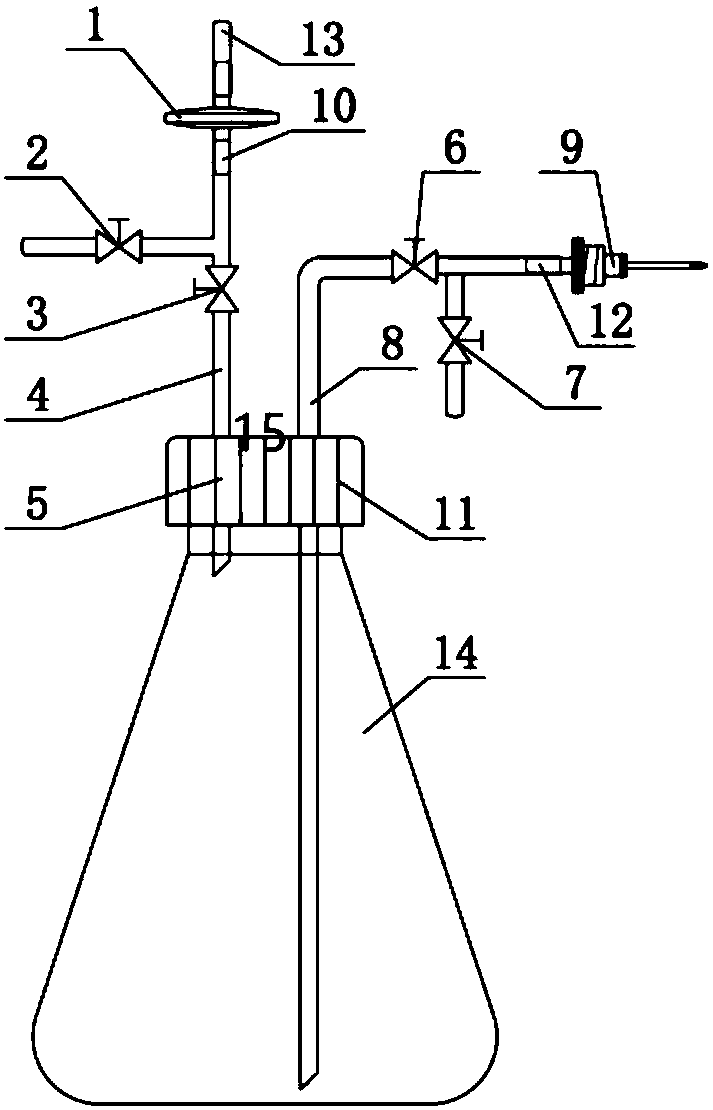

[0113] Such as figure 1 Make inoculation device as shown, this inoculation device comprises threaded mouth triangular flask 14 and hollow bottle cap 5, passes into a stainless steel two-way 15 in hollow bottle cap 5, and sealing gasket 11 is arranged in threaded bottleneck 14 and bottle cap 5.

[0114] Two valves are housed on the inflow pipe 4 of the stainless steel two-way 15, one inflow pipe main valve 3, one inflow pipe purge valve 2. The air inlet is connected with the stainless steel inflow pipe 4 with a flexible pipe 10, and connected to the microporous membrane filter 1, and the microporous membrane filter 1 is connected with a section of flexible pipe as the air inlet 13 during deoxygenation.

[0115] Stainless steel two-way 15 outflow pipe 8 is equipped with two valves, one outflow pipe main valve 6, one outflow pipe purge valve 7;

Embodiment 2

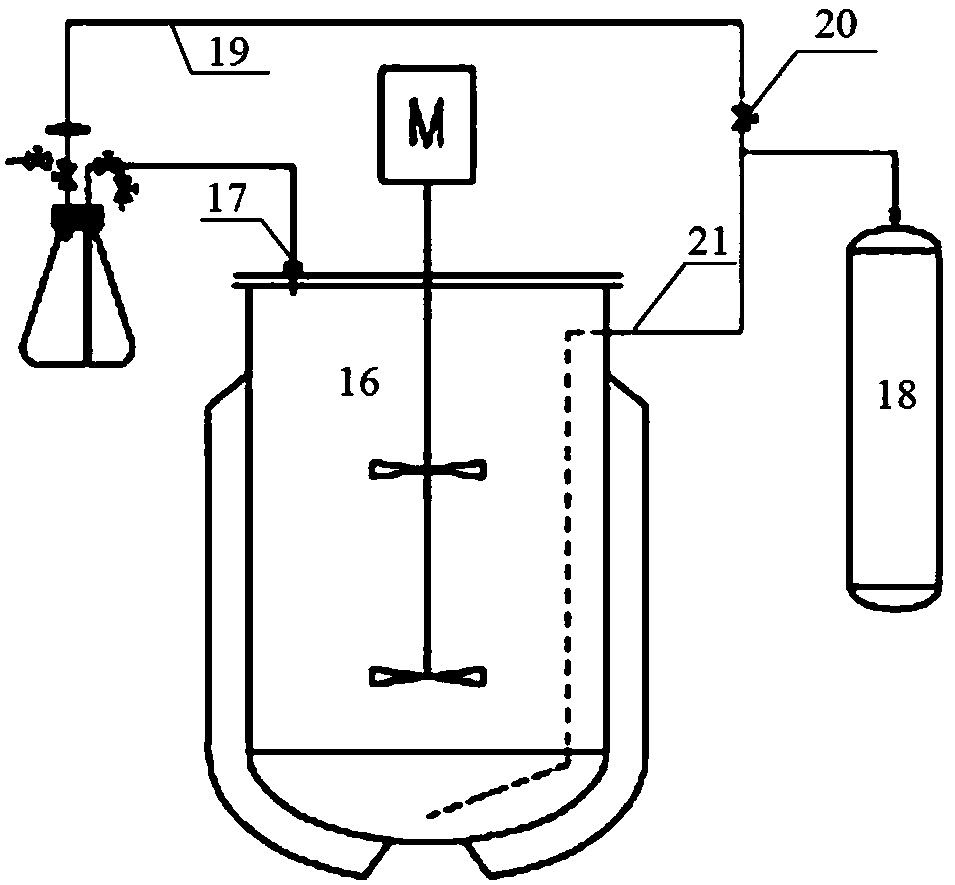

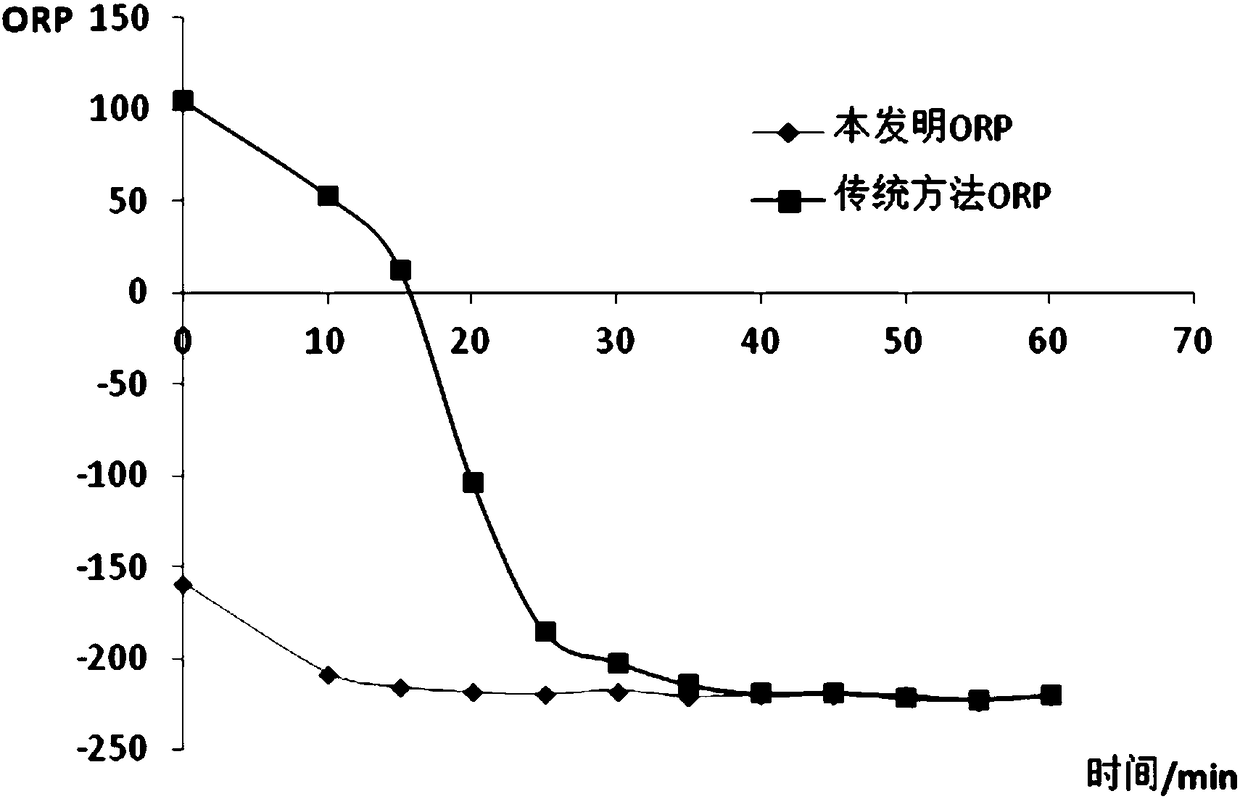

[0117] Taking a 50L fermenter as an example, Moorella thermoacetica, ATCC49707 is used for fermentation, and syngas is used as the gas raw material to produce acetic acid.

[0118] The composition content of the synthesis gas is shown in Table 1 below.

[0119] Table 1: Contents of each component of synthesis gas

[0120] components

Content (volume percent)

H 2 (%)

44~51%

CO(%)

2.5~20.0%

CO 2 (%)

18~30%

[0121] Medium components: Potassium dihydrogen phosphate, dipotassium hydrogen phosphate, ammonium sulfate, magnesium sulfate heptahydrate, yeast extract, morphine ethanesulfonic acid, trace element solution ATCC 1754 PETC, resin azure.

[0122] In fermentor, feed steam and maintain pressure at 0.1MPa to sterilize for 30 minutes, then pass the gas in Table 1 into fermentor, insert bacterial classification Moorella thermoacetica (ATCC 49707 ) (http: / / www.atcc.org), the reaction temperature is controlled at 60°C, the pH is 7.0,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com