Design method using double slit metallic structure to realize surface wave energy directional transmission

A metal structure, directional transmission technology, applied in optics, instruments, optical components, etc., can solve problems such as uncontrollable surface waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection of the present invention is not limited to the following embodiments, but should include all content in the claims; All the contents in the claims are realized.

[0037] The concrete steps of the embodiment of the present invention are as follows:

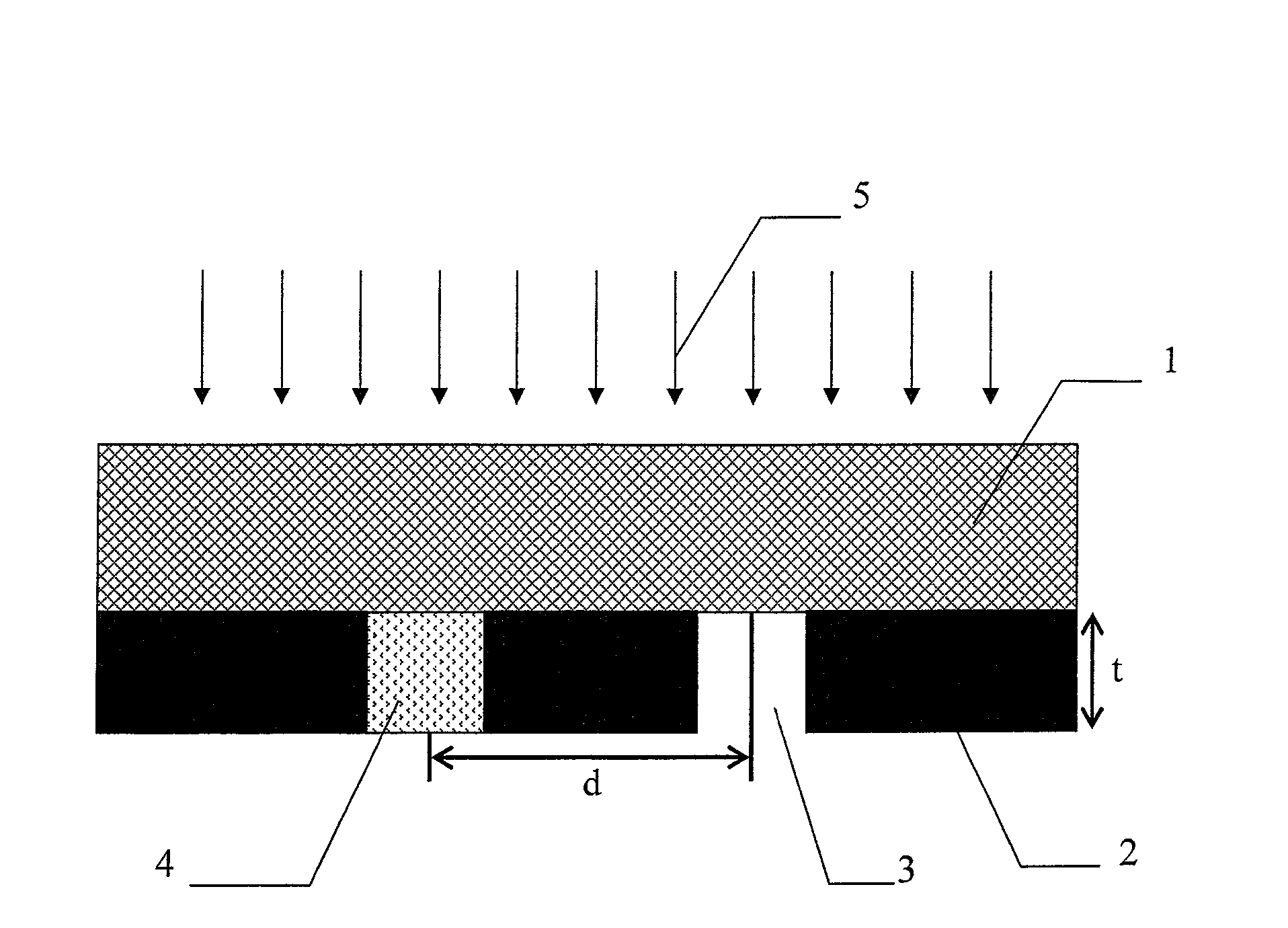

[0038] (1) Determine the incident wavelength λ to be 632.8nm, choose silica S i o 2 The material is used as a substrate, and a 200nm metal silver layer is evaporated on its surface, that is, t=200mm;

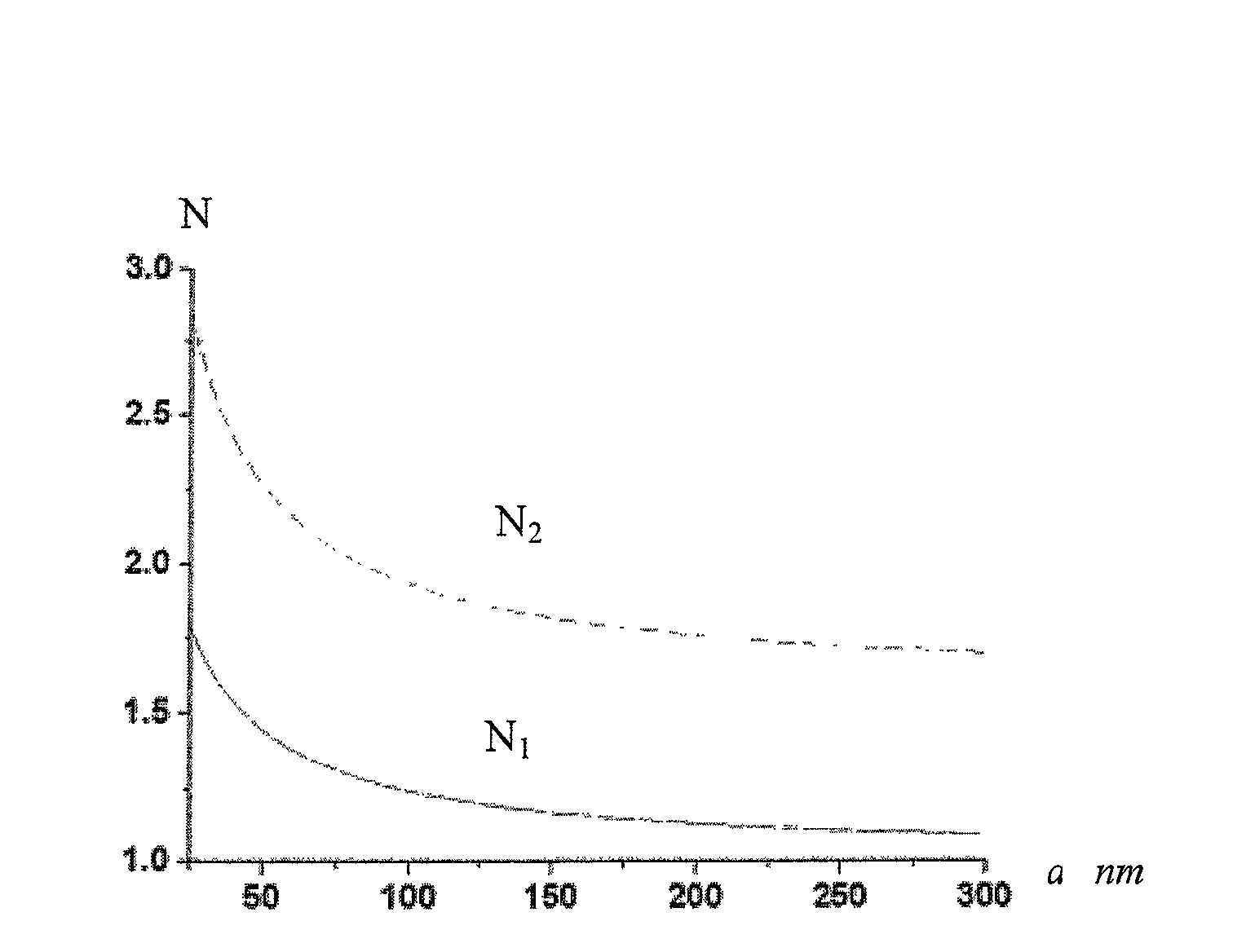

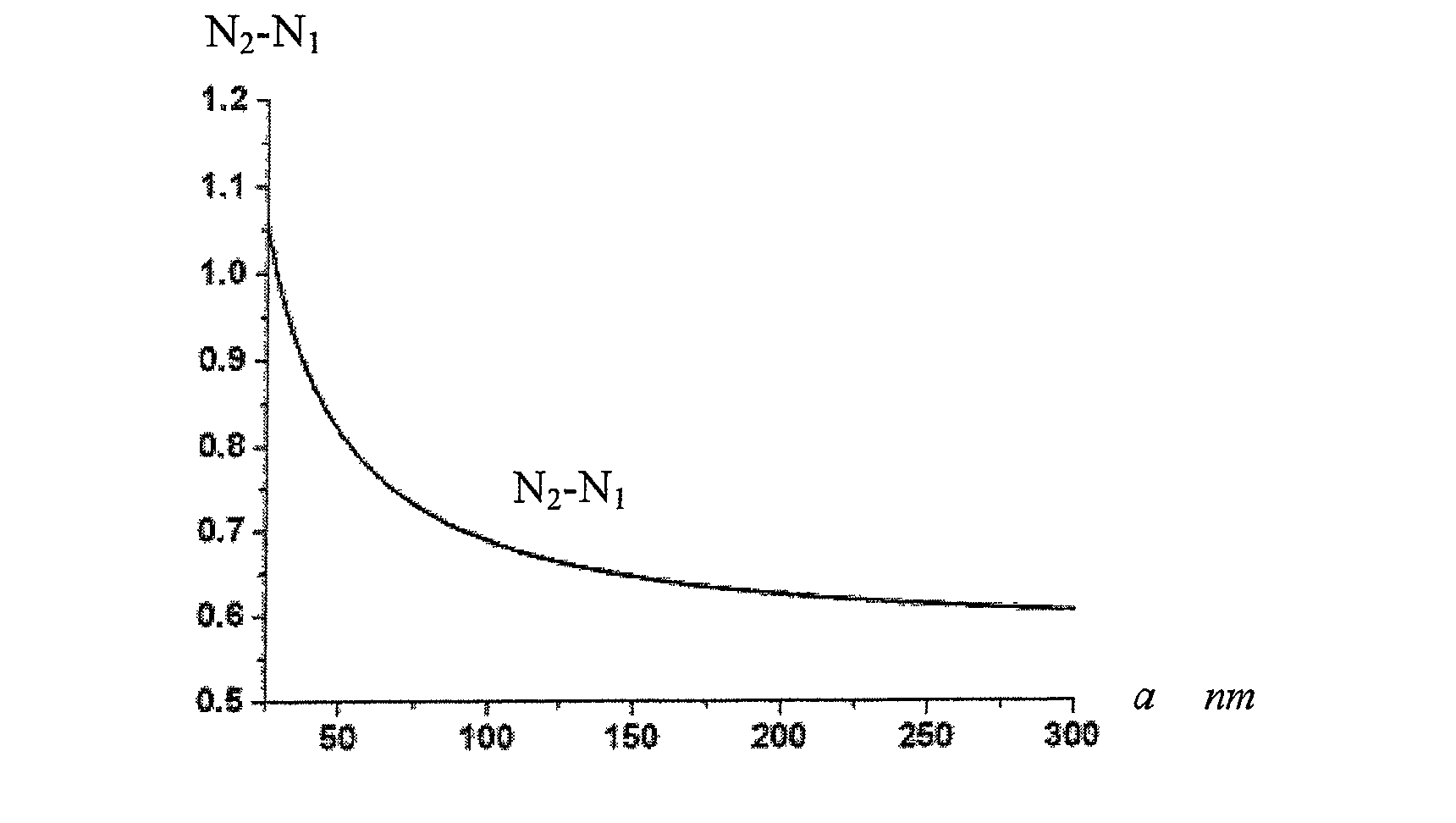

[0039] (2) Open two slit structures with a width a on the silver layer, and the distance between the centers of the two slits is d;

[0040] (3) Choose air and n 2 The dielectric material of =1.52 fills two metal slits respectively, and the refractive index n of air 1 = 1, the incident light is incident perpendicular to the other surface of the substrate, assuming that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com