Machine for processing sheet made of printing carriers

A technology for substrates and sheets, applied in printing machines, printing, object supply, etc., can solve the problems of complex control of adjustment drives, and achieve the effect of simple structure, reliable function, and reasonable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

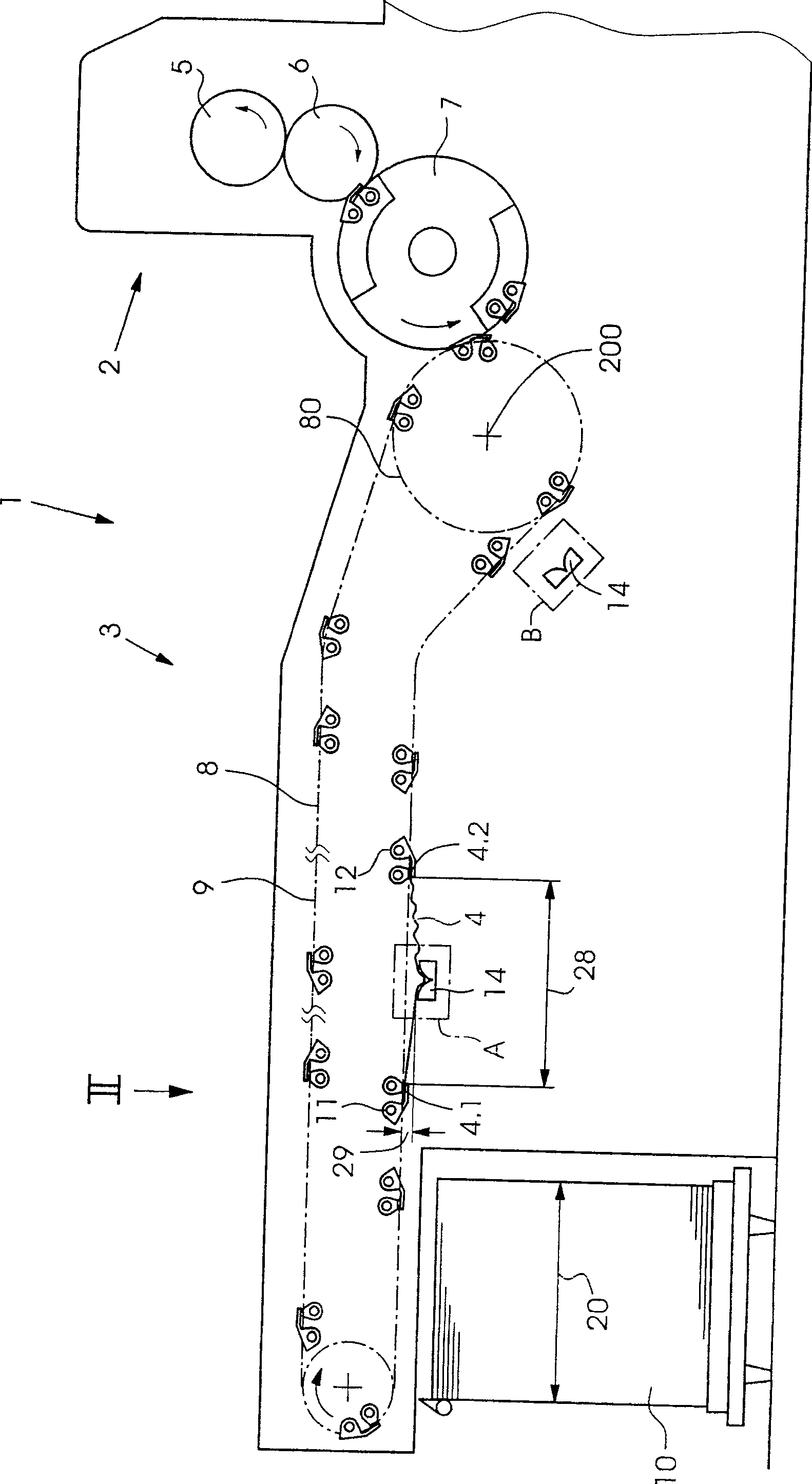

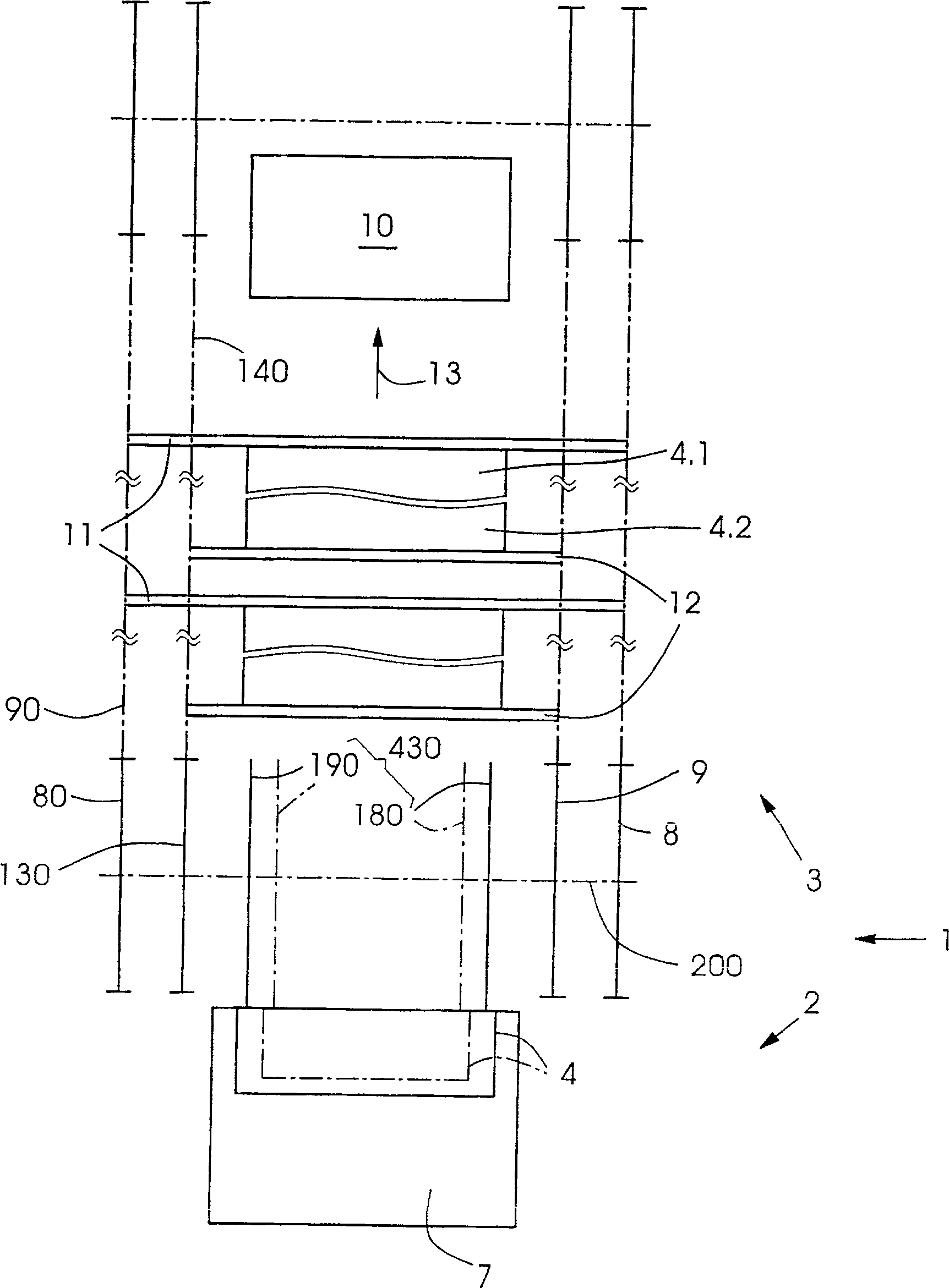

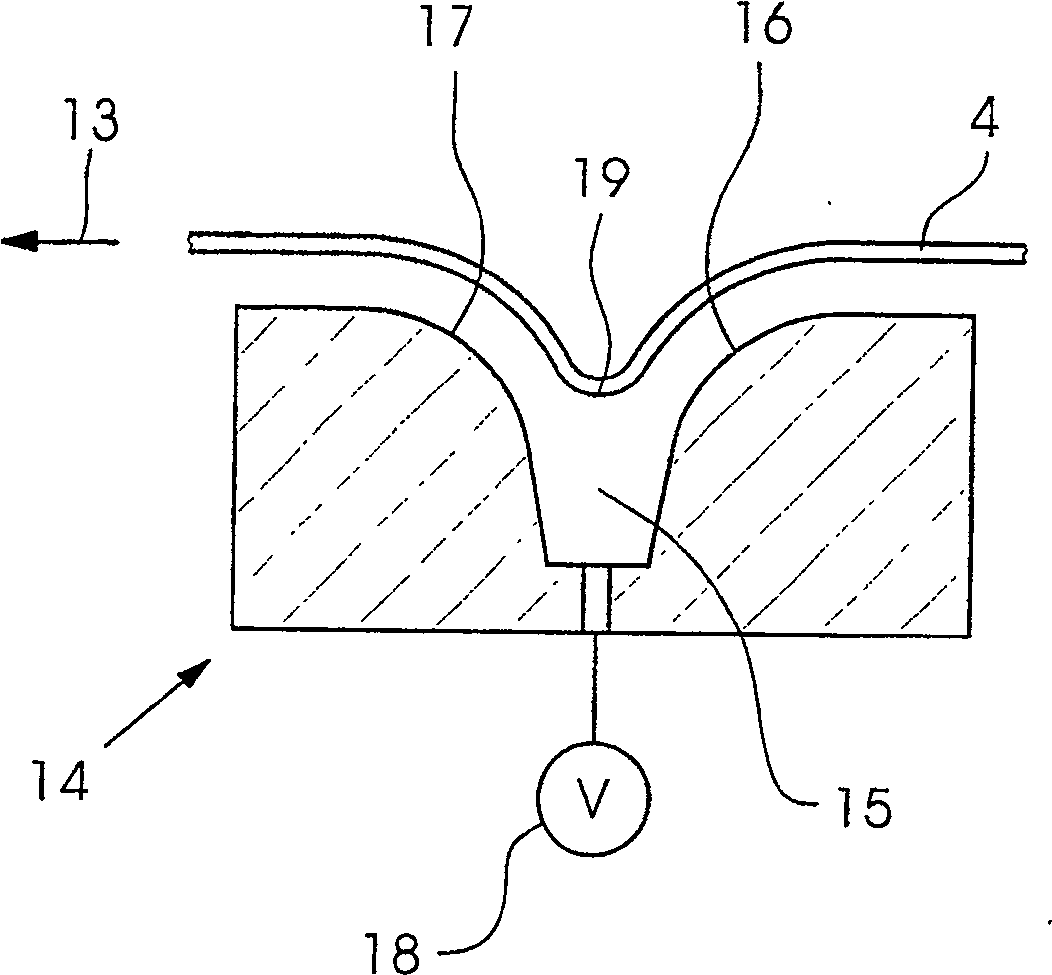

[0031] figure 1 A printing press 1 is shown which has an offset printing unit 2 and a delivery 3 for sheets 4 of printing stock having a sheet length 20 . The printing unit 2 comprises a plate cylinder 5 , a blanket cylinder 6 and an impression cylinder 7 for offset printing. The delivery 3 has a first chain conveyor 8 and a second chain conveyor 9 as sheet conveying means, which convey the sheets 4 to a delivery pile 10 and in this case circulate synchronously with each other run. The first chain conveyor 8 includes a front gripper bridge 11 for gripping the sheet 4 at each front running sheet end 4.1 or edge, and the second chain conveyor 9 includes a Each rear gripper bridge 12 grips the sheet 4 at the rear running sheet end 4.2 or edge. These gripper bridges 11 , 12 function as gripping devices for holding the sheet 4 at both ends. The first chain conveyor 8 comprises a pair of endless chain belts 90 between which the front gripper bridges 11 are carried, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com