Metal Mg, Ca and Sr reducing apparatus

A metal magnesium and equipment technology, applied in the field of metal reduction equipment, can solve the problems of high labor intensity, unsatisfactory reduction effect of feeding and slag discharge, long feeding and slag discharge time, etc., so as to reduce labor intensity, improve reduction effect, and simplify Effects of feeding and slagging operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

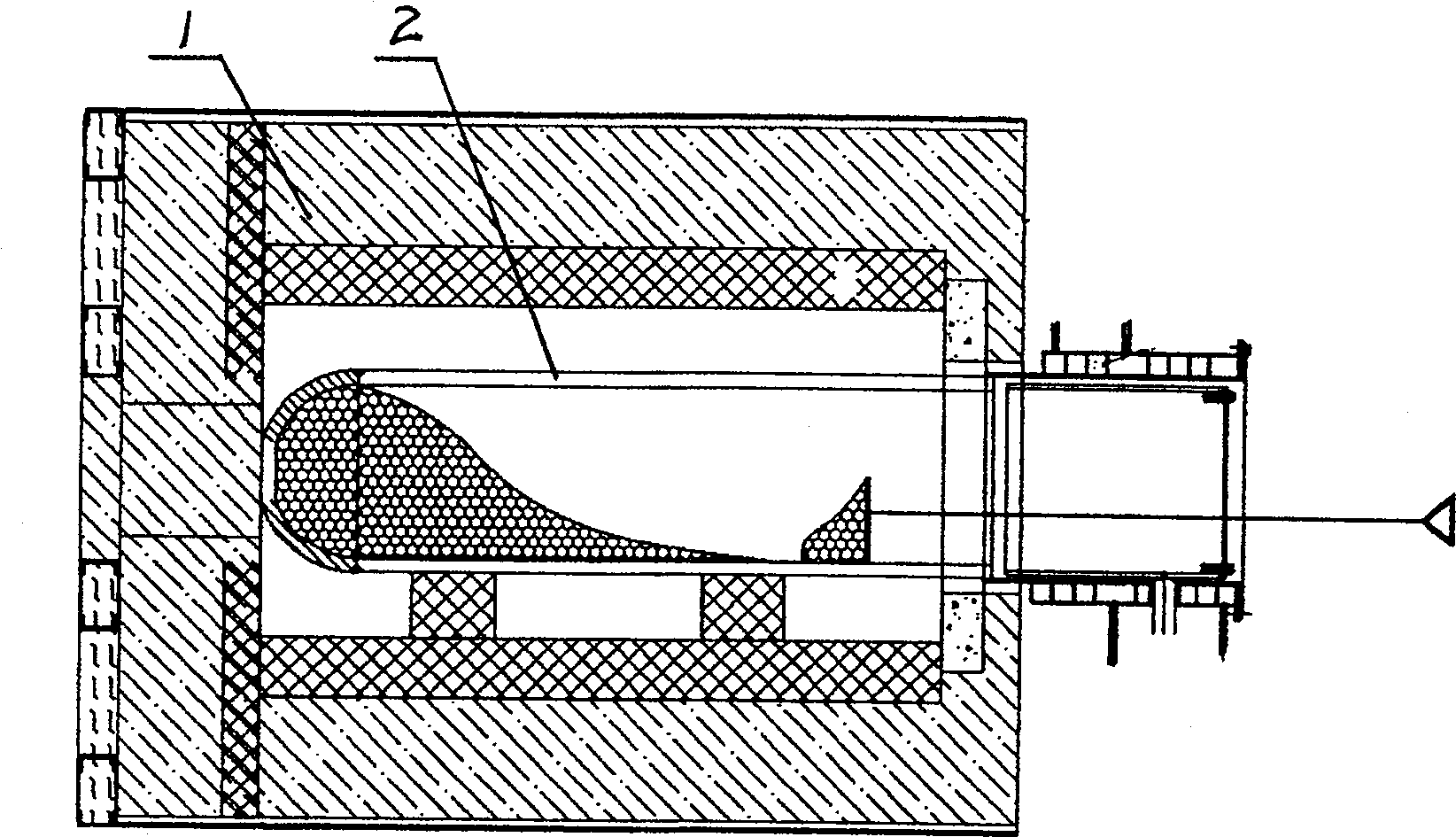

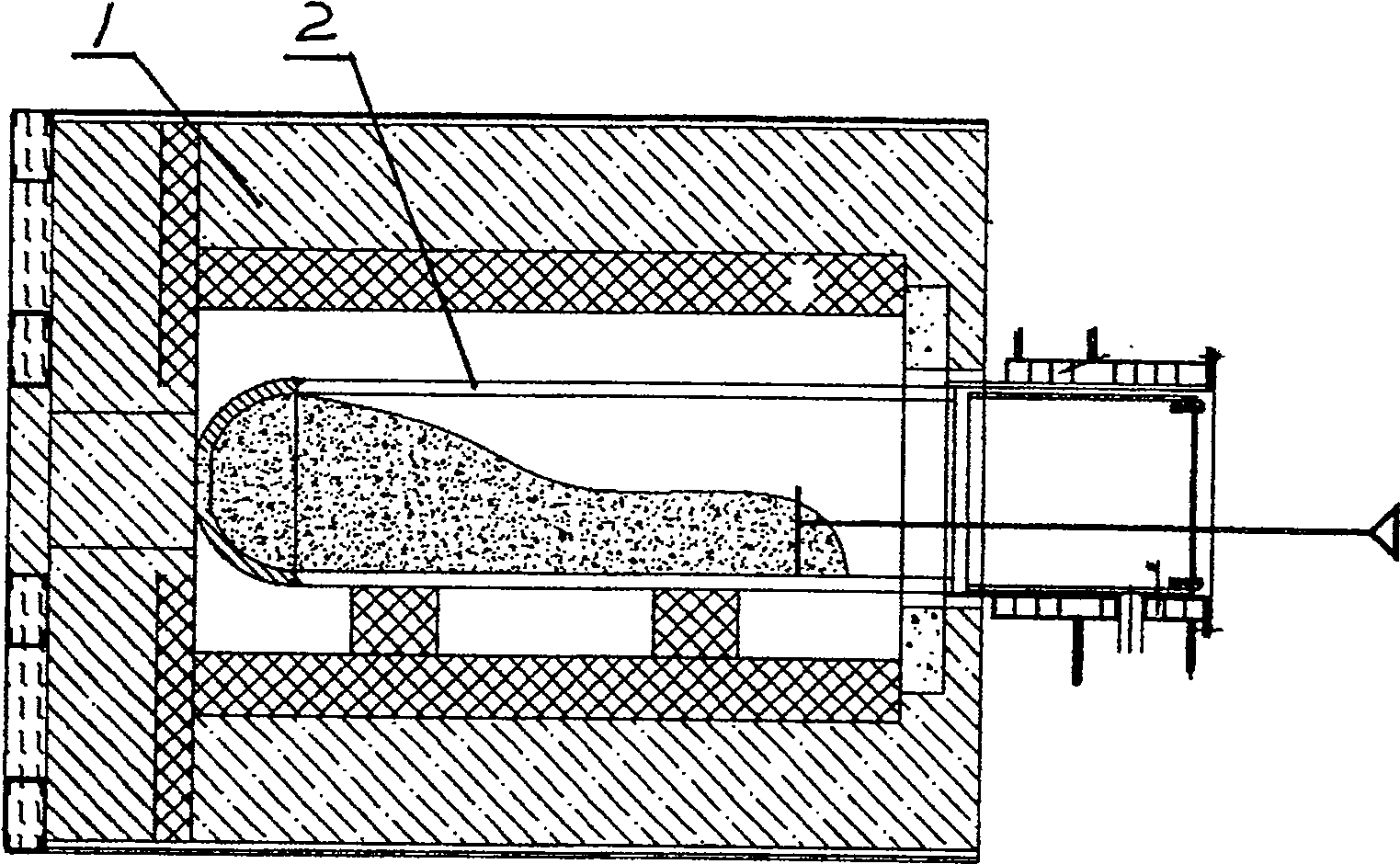

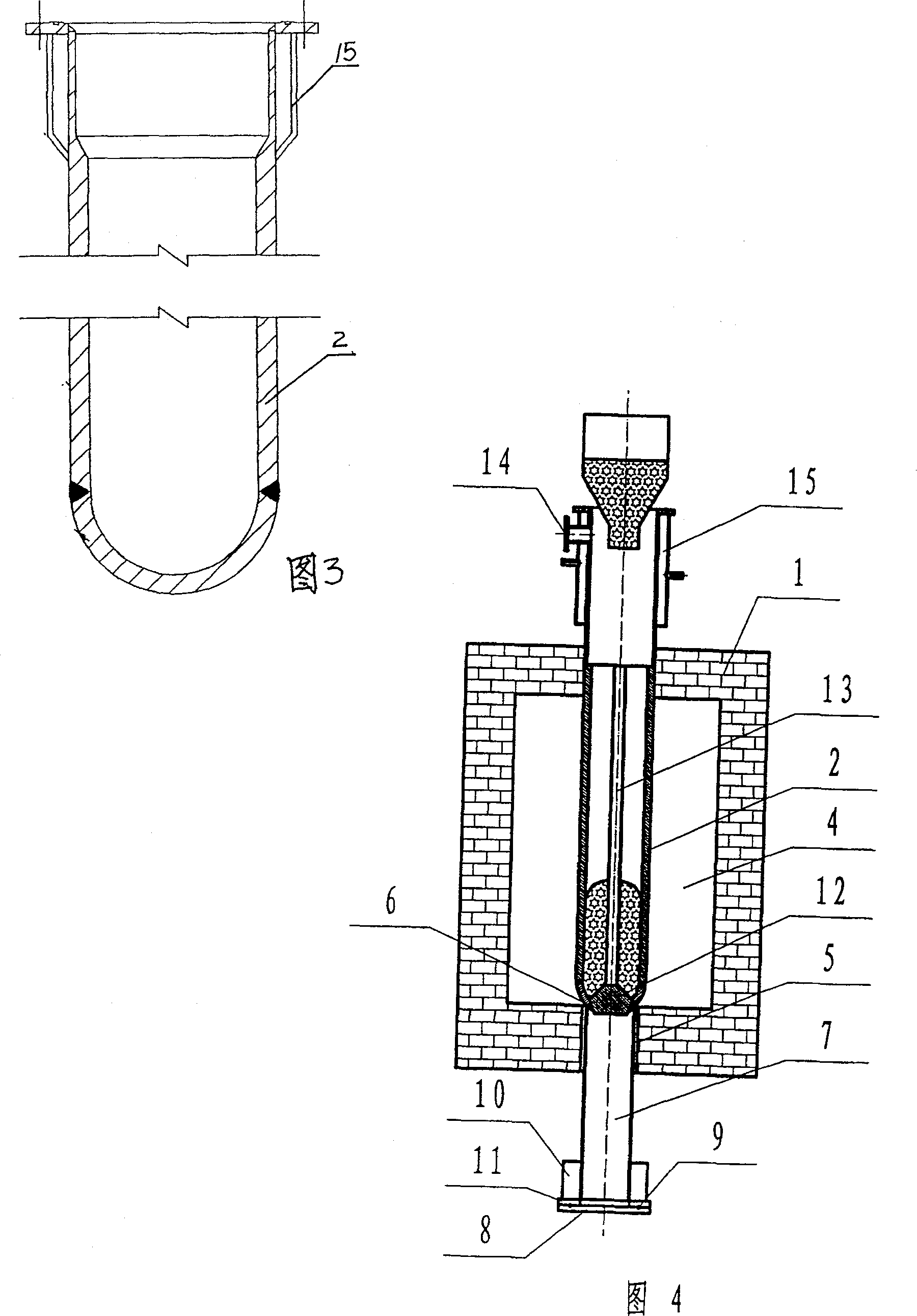

[0015] Metal magnesium, calcium, and strontium reduction equipment includes a reduction furnace 1 and a reduction tank 2 placed in the reduction furnace. The bottom of the reduction furnace 1 is provided with a support frame 3. The furnace 4 of the reduction furnace is a vertical furnace. The top of the furnace 4 is opened. There is an upper furnace mouth and a lower furnace mouth 5 at the bottom; a slag outlet 6 is opened at the bottom of the reduction tank, and a slag discharge pipe 7 is fixed at the bottom of the reduction tank, and the lower end of the slag discharge pipe is provided with a sealing cover 8 and a sealing cover 8 A sealing ring 9 is provided between the slag discharge pipe 7, and a water jacket 10 with inlet and outlet pipe ports is provided at the lower section of the slag discharge pipe. There is a flange connection between the sealing cover 8 and the slag discharge pipe 7, that is, a flange 11 is provided at the bottom of the slag discharge pipe, the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com