Filtrate reducer for oil field well drilling fluid

A fluid loss reducer, oil field drilling technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as irreversible degradation, limited synergy between sulfomethyl lignite and lignosulfonate, and reduction in efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

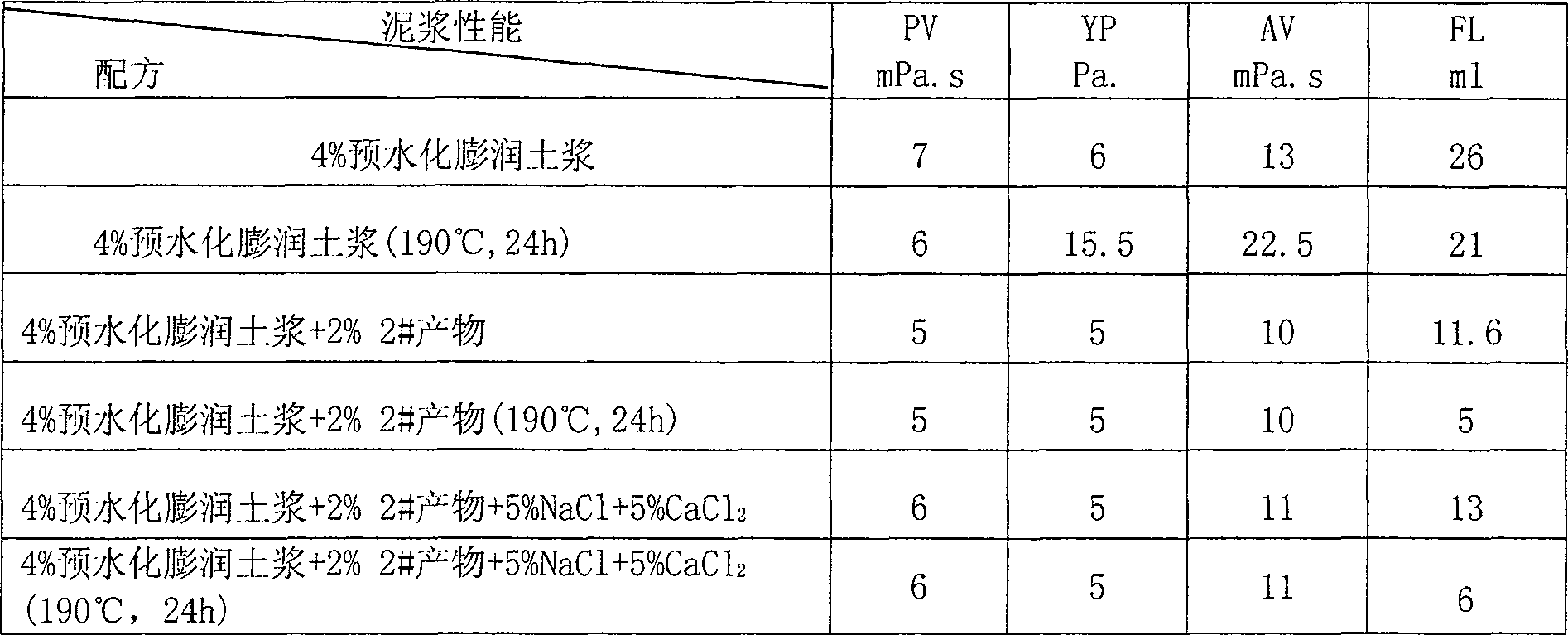

Examples

example 1

[0039] Get 100 grams of sulfomethyl lignite, dissolve in water, add 10 grams of sodium lignosulfonate, 3 grams of dimethyl diallyl ammonium chloride, 0.01 gram of ferric chloride (FeCl 3 ), and stir well.

[0040] Pour the solution into the reaction kettle (or directly mix in the reaction kettle), turn on the stirring, and react at 150°C for 2 hours, and the pressure is normal pressure. After the reaction, the product is a black liquid, and the product 1# is obtained after evaporating the water. The product is a black powder with good water solubility.

example 2

[0042] Take 100 grams of sulfomethyl lignite, dissolve it in water, add 25 grams of sodium lignosulfonate, 10 grams of dimethyl diallyl ammonium chloride, and 0.05 grams of ferric chloride, and stir evenly.

[0043] Pour the solution into the reaction kettle (or directly mix in the reaction kettle), turn on the stirring, and react at 120°C for 4 hours, and the pressure is normal pressure. After the reaction, the obtained product is a black liquid, and the product is obtained after evaporating the water. The product is black powder 2# and has good water solubility.

example 3

[0045] Take 100 grams of sulfomethyl lignite, dissolve it in water, add 50 grams of sodium lignosulfonate, 15 grams of dimethyl diallyl ammonium chloride, and 0.52 grams of ferric chloride, and stir evenly.

[0046] Pour the solution into the reaction kettle (or directly mix in the reaction kettle), turn on the stirring, and react at 85° C. for 6 hours, and the pressure is normal pressure. After the reaction, the obtained product is a black liquid, and the product is obtained after evaporating the water. The product is a black powder 3# with good water solubility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com