Biogas and leachate integrated pumping and drainage system for garbage landfill

A landfill and biogas technology, applied in waterway systems, sewage removal, drainage structures, etc., can solve problems such as unsatisfactory biogas and leachate pumping and drainage effects, and poor permeability of garbage bodies, and achieve later maintenance. The effect of convenient management, convenient adjustment and processing, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

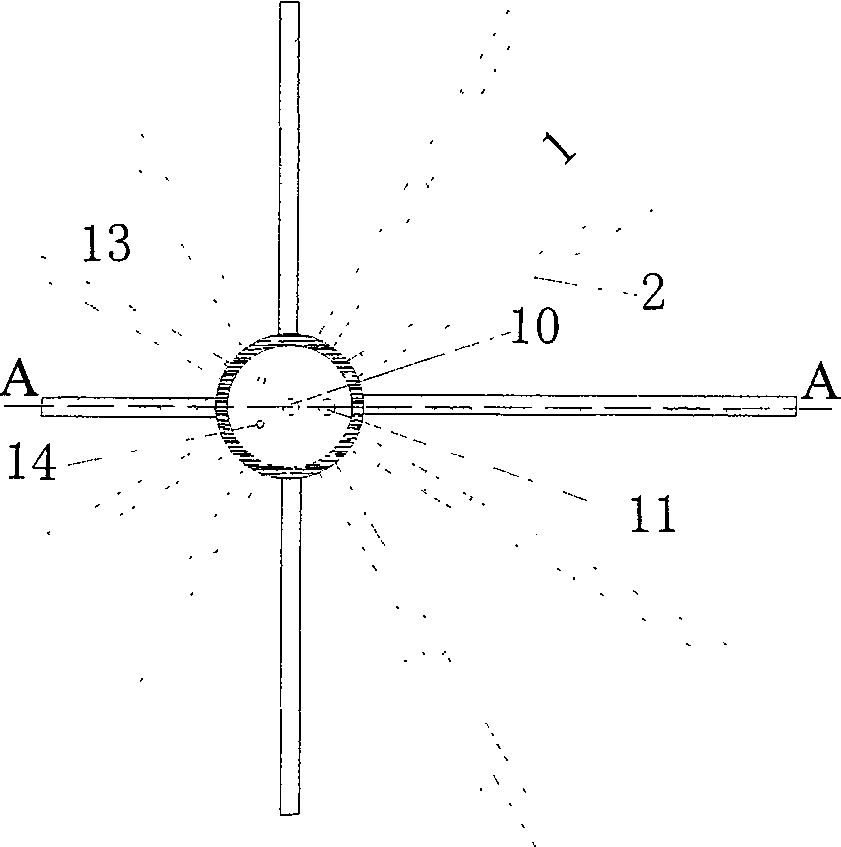

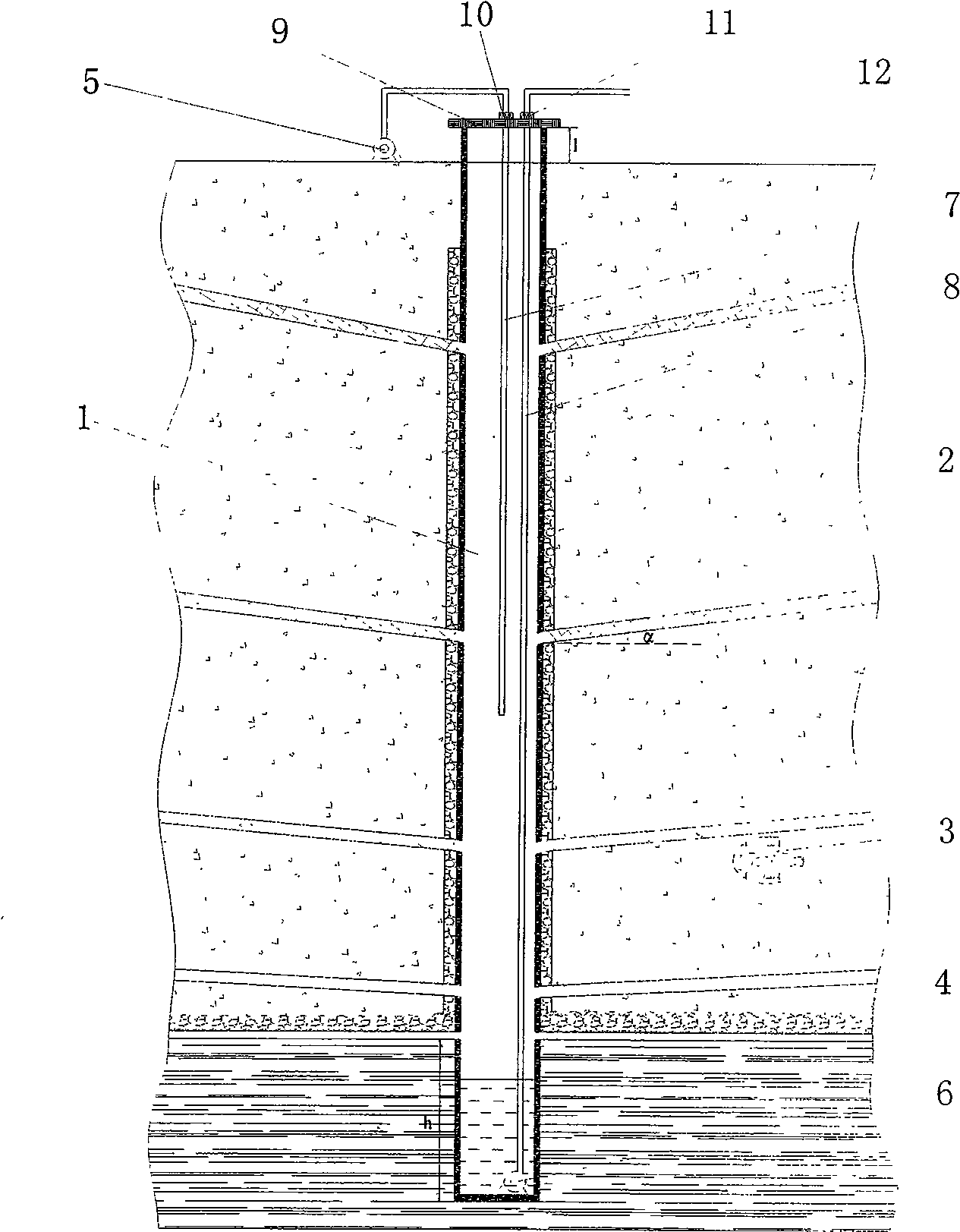

[0011] The extraction system of the present invention is a combination of a liquid collection well and a gas recovery well, figure 2 As shown, a shaft 1, a multi-branch collection and drainage channel 2, an air suction pump 5, a submersible sewage pump 6, an air extraction pipe 7, a drain pipe 8, and a sealing cover 9 are involved. The construction of the vertical shaft 1 is completed before the landfill is put into use, and the height l of the wellhead above the closure of the landfill is 300-500mm; the height h between the bottom of the well and the bottom of the drainage layer 4 is 3000-5000mm. The shaft wall is constructed of reinforced concrete material with strong deformation resistance, and multiple horizontal holes are reserved in the shaft wall to communicate with the multi-branch collection and drainage channel 2 when the garbage 12 is land...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com