Reciprocating self-climbing type climbing form system and its climbing form method

A climbing formwork and self-climbing technology, which is applied in the field of reciprocating self-climbing climbing formwork system and its climbing formwork, can solve the problem that the selection and operation of construction tower cranes and concrete placing booms are greatly affected, the reciprocating self-climbing cycle cannot be formed, and no climbing is set. Problems such as installation and installation can be shortened to shorten the construction period, reduce the construction cost and shorten the climbing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

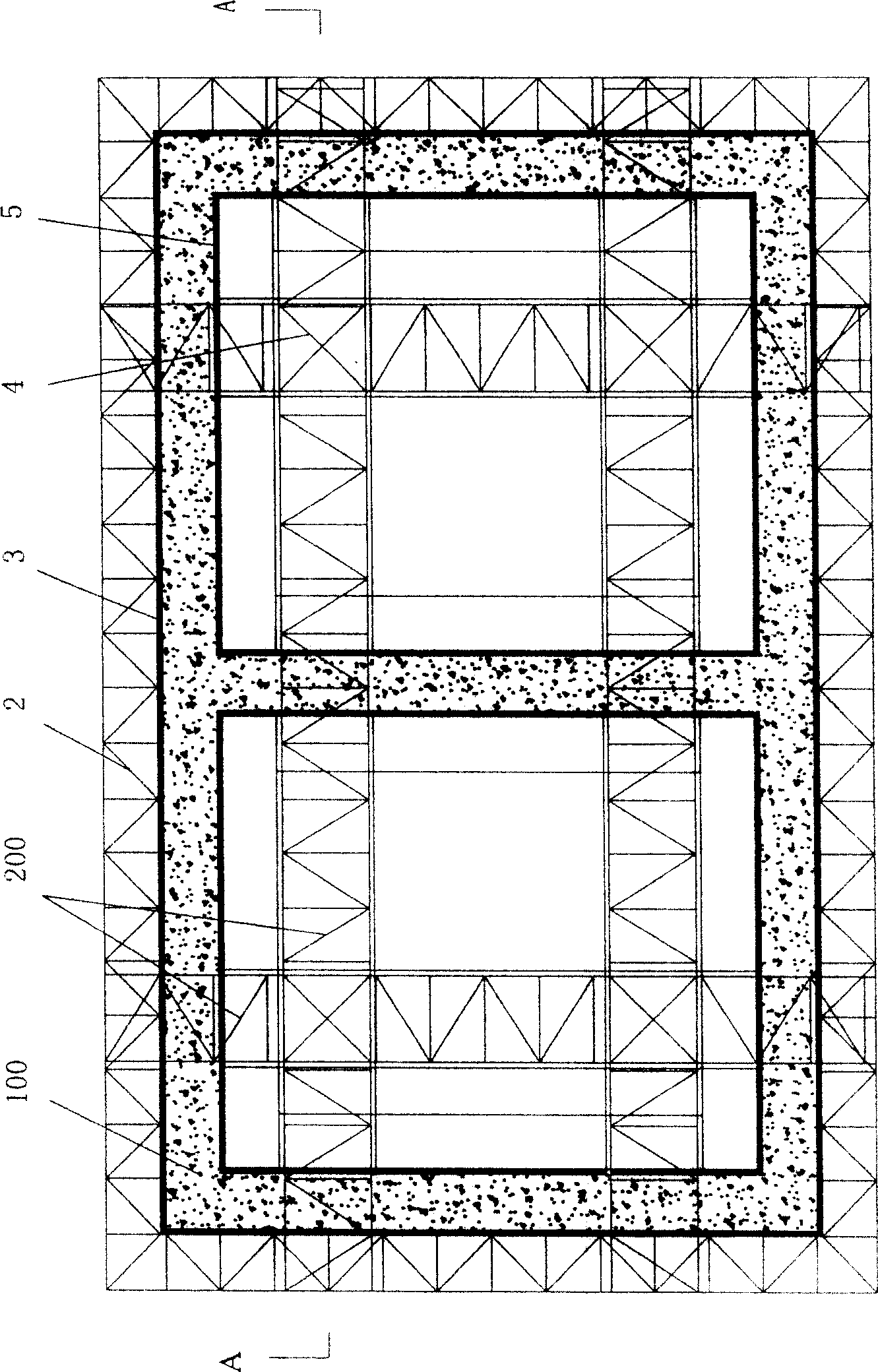

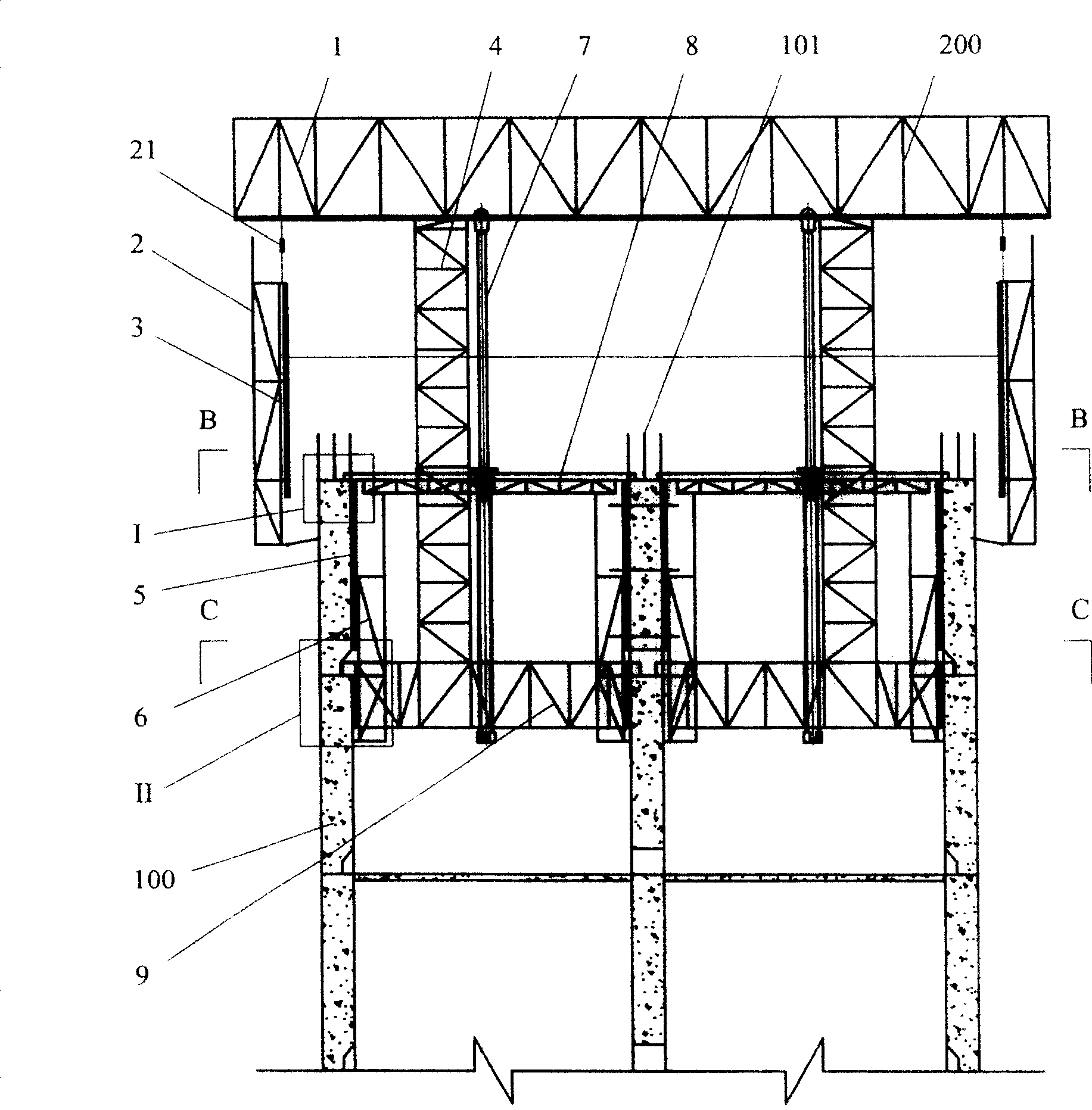

[0051] Figure 1 to Figure 6 Embodiment 1 of a reciprocating self-climbing climbing formwork system of the present invention is shown. Such as figure 1 , figure 2 As shown, the climbing formwork system includes a carrier frame body 200, an operating inner platform 8, a lifting device 7 connecting the carrier frame body 200 and the operating inner platform 8, an outer scaffold 2 positioned outside the building wall 100, an outer formwork 3 and a Inner scaffolding 6 and inner formwork 5 on the inner side of body of wall 100 .

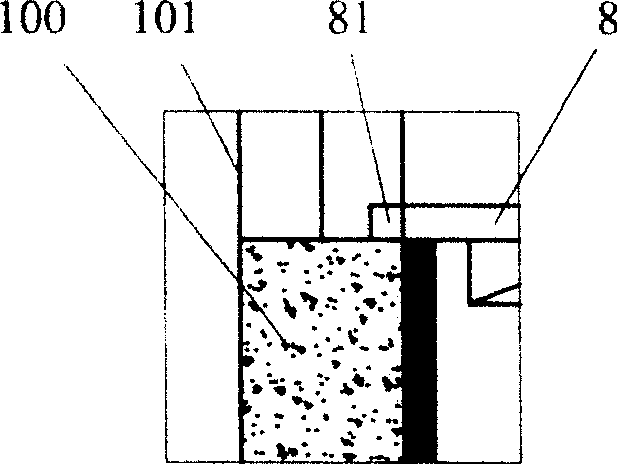

[0052] The bearing frame body 200 comprises an upper bearing frame 1, a lower bearing beam 9, a bearing column 4 connecting the upper bearing frame 1 and the lower bearing beam 9, the operating platform 8 is located between the upper bearing frame 1 and the lower bearing beam 9, and the bearing column 4 passes through Through the opening on the operating platform 8 and can move in the hole.

[0053] The outer scaffolding 2 is fixedly connected to the...

Embodiment 2

[0075] Figure 15 The second embodiment of a reciprocating self-climbing climbing formwork system of the present invention is shown, which is the application of a reciprocating self-climbing climbing formwork system of the present invention on a single-sided building wall. Such as Figure 15 as shown,

[0076] The climbing formwork system includes a load frame body 200, an operating platform 8, a lifting device 7 connecting the load frame body 200 and the operation platform 8, the left scaffold 2a, the left formwork 3a and the right scaffold 6a located on both sides of the building wall 100 , the right template 5a.

[0077] The bearing frame body 200 comprises an upper bearing frame 1, a lower bearing beam 9, a bearing column 4 connecting the upper bearing frame 1 and the lower bearing beam 9, the operating platform 8 is located between the upper bearing frame 1 and the lower bearing beam 9, and the bearing column 4 passes through Through the opening on the operating platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com