Rotary sonic surface wave motor

A surface acoustic wave, rotary-type technology, applied in the direction of generators/motors, electrical components, piezoelectric effects/electrostrictive or magnetostrictive motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

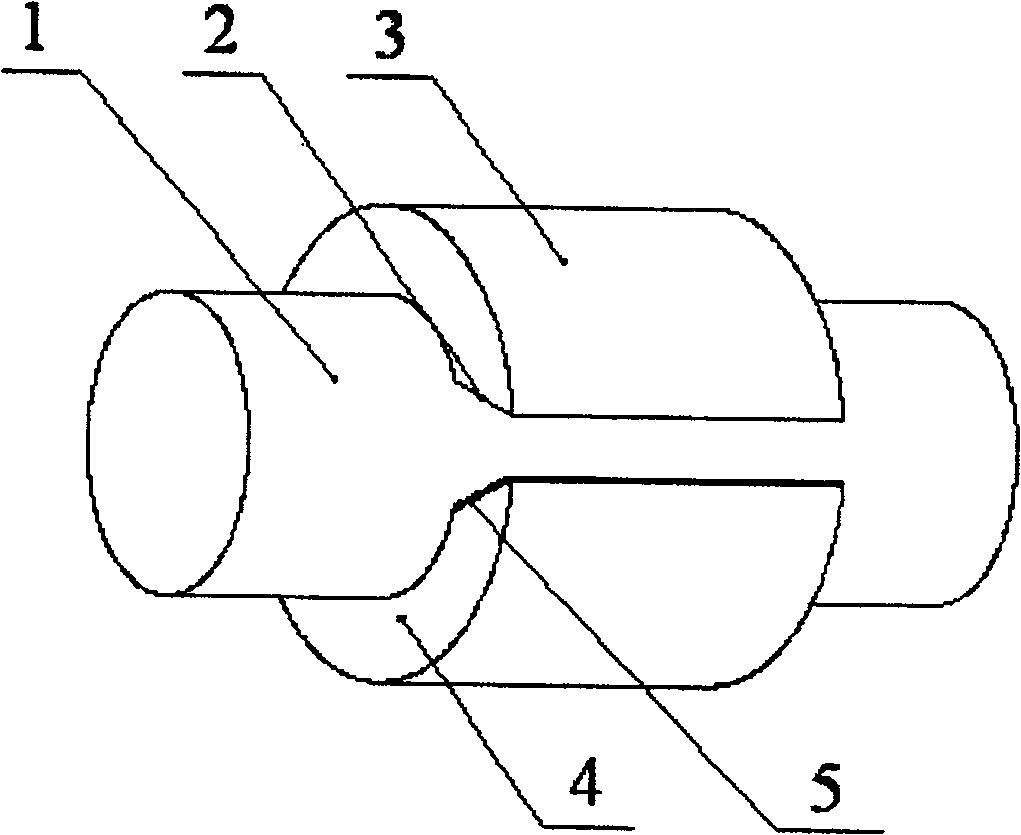

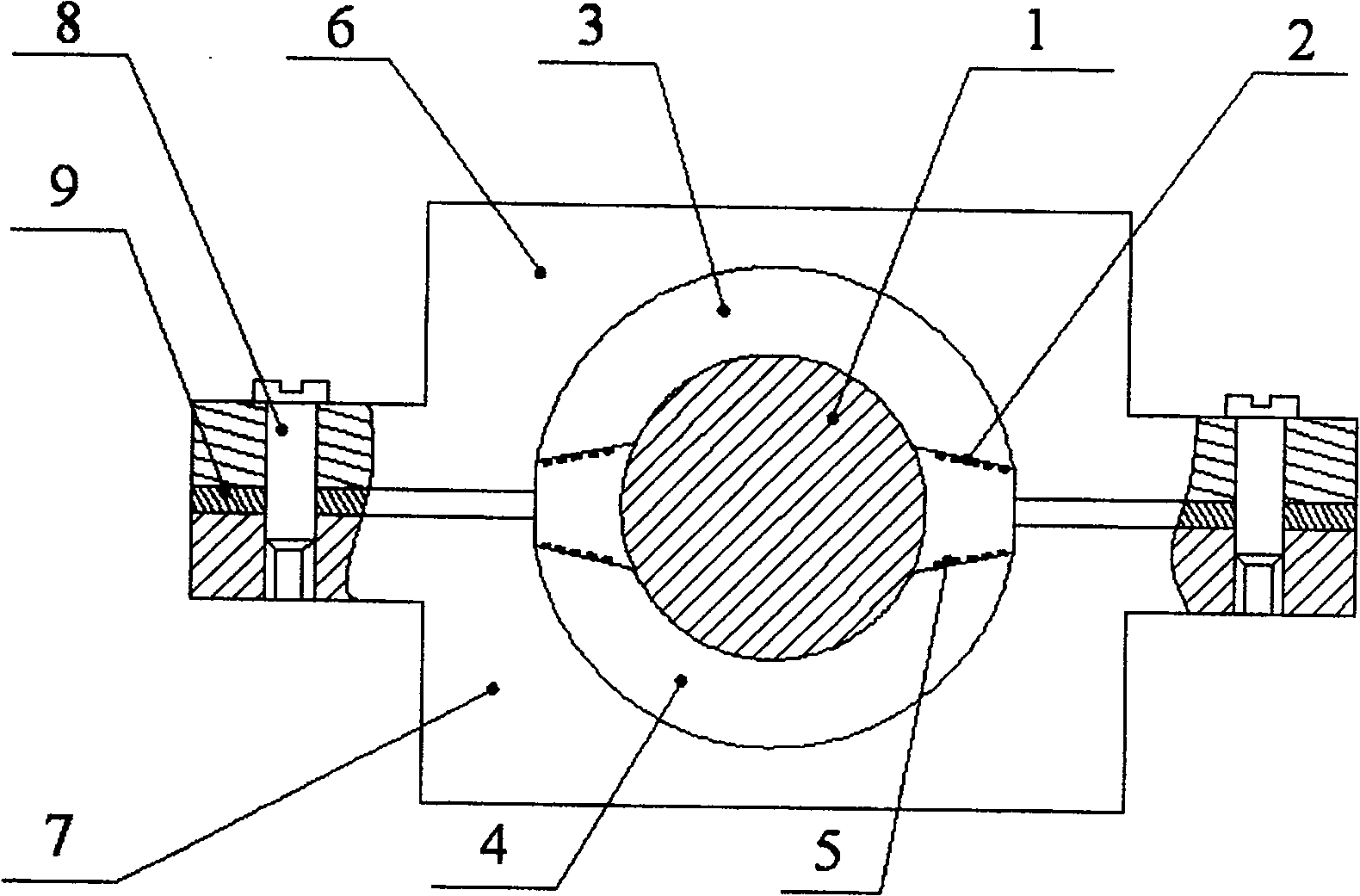

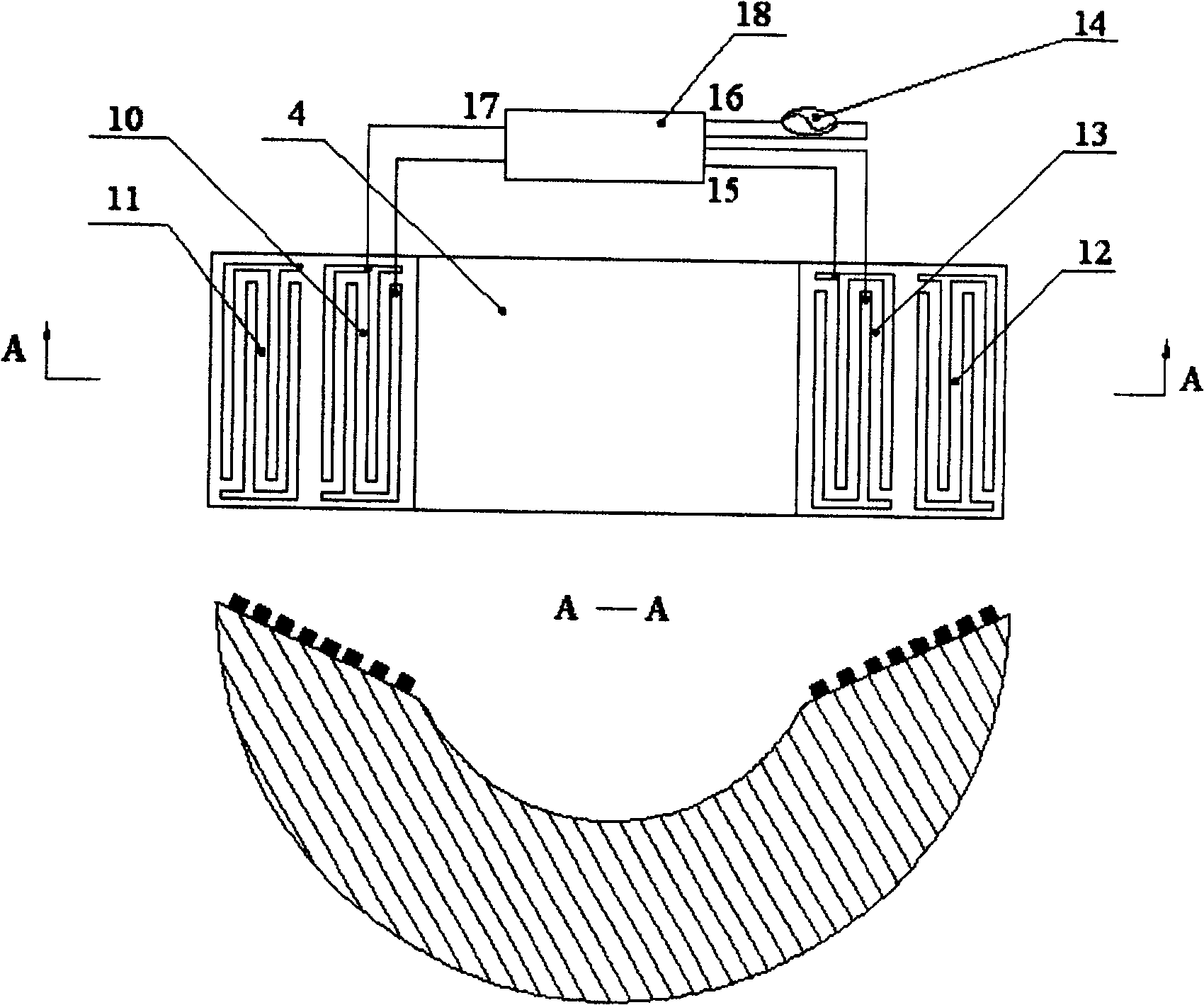

[0023] The working principle and specific implementation of the rotary surface acoustic wave motor will be described in detail below.

[0024] to combine figure 1 and figure 2 As shown, it is composed of a stator assembly, an interdigital transducer, a rotor and a bracket assembly. It is characterized in that: the stator assembly includes an upper stator half ring 3 and a lower stator half ring 4 opposite to it, wherein the upper stator half ring The opposite end surfaces of the ring 3 and the lower stator half ring 4 respectively form a slope shape indented from the outer ring surface to the inner ring surface; the rotor 1 is clamped in the middle by the upper stator half ring 3 and the lower stator half ring 4, and the rotor 1. The surface is covered with micron-scale bosses; the interdigital transducers include upper and lower two sets of interdigital transducer pairs, which are energy circulation structure, wherein the upper interdigital transducer pair 2 is processed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com