Minitype vertical type liquid canned machine

A filling machine and vertical technology, applied in the field of small vertical liquid filling machines, can solve the problems of difficult installation and debugging, inconvenient use and high cost, and achieve a simple and reliable main control mechanism, easy adjustment and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the present invention, below in conjunction with embodiment is described in more detail.

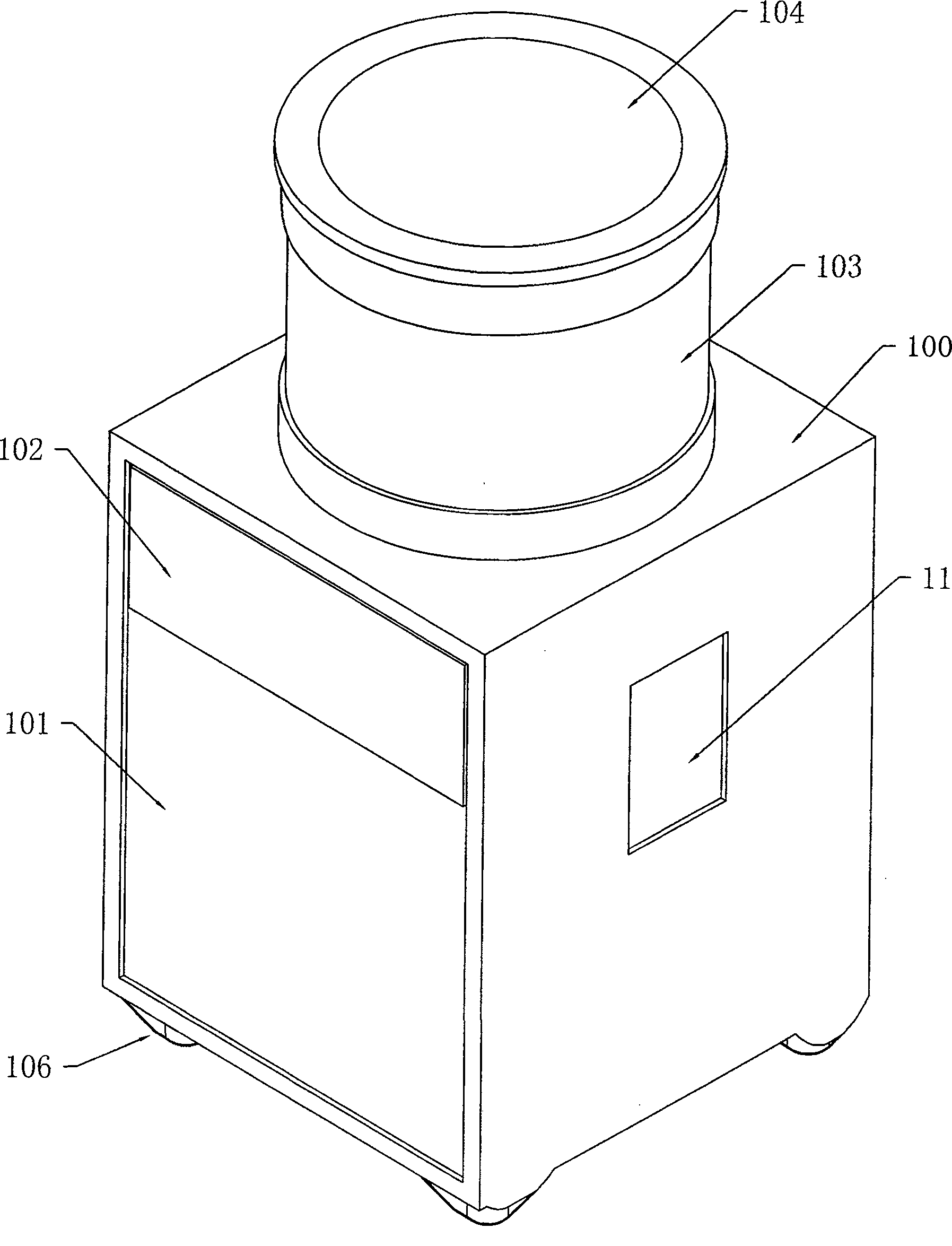

[0025] figure 1 It is the front view of the whole machine of the small vertical liquid filling machine of the present invention. A liquid tank 103 is arranged on the cubic cylinder type cabinet 100. There is an openable tank cover 104 on the liquid tank 103. There is a door 101 and a control panel in front of the cabinet 100. 102, bag storehouse 11 is arranged on the side, and the four jiaos under the cabinet 100 respectively have machine wheel 106, are convenient to move, and the cabinet 100 is provided with packing assembly.

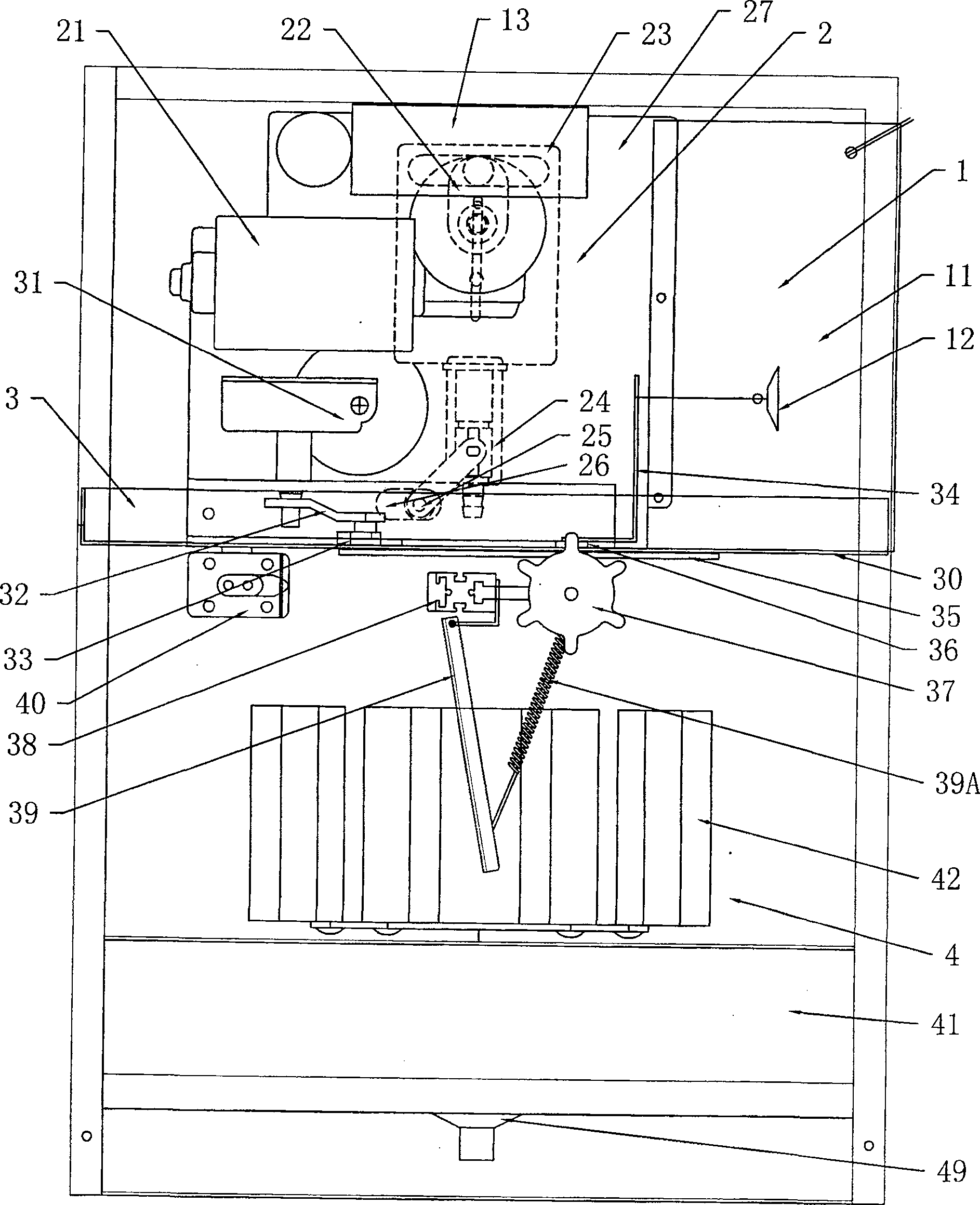

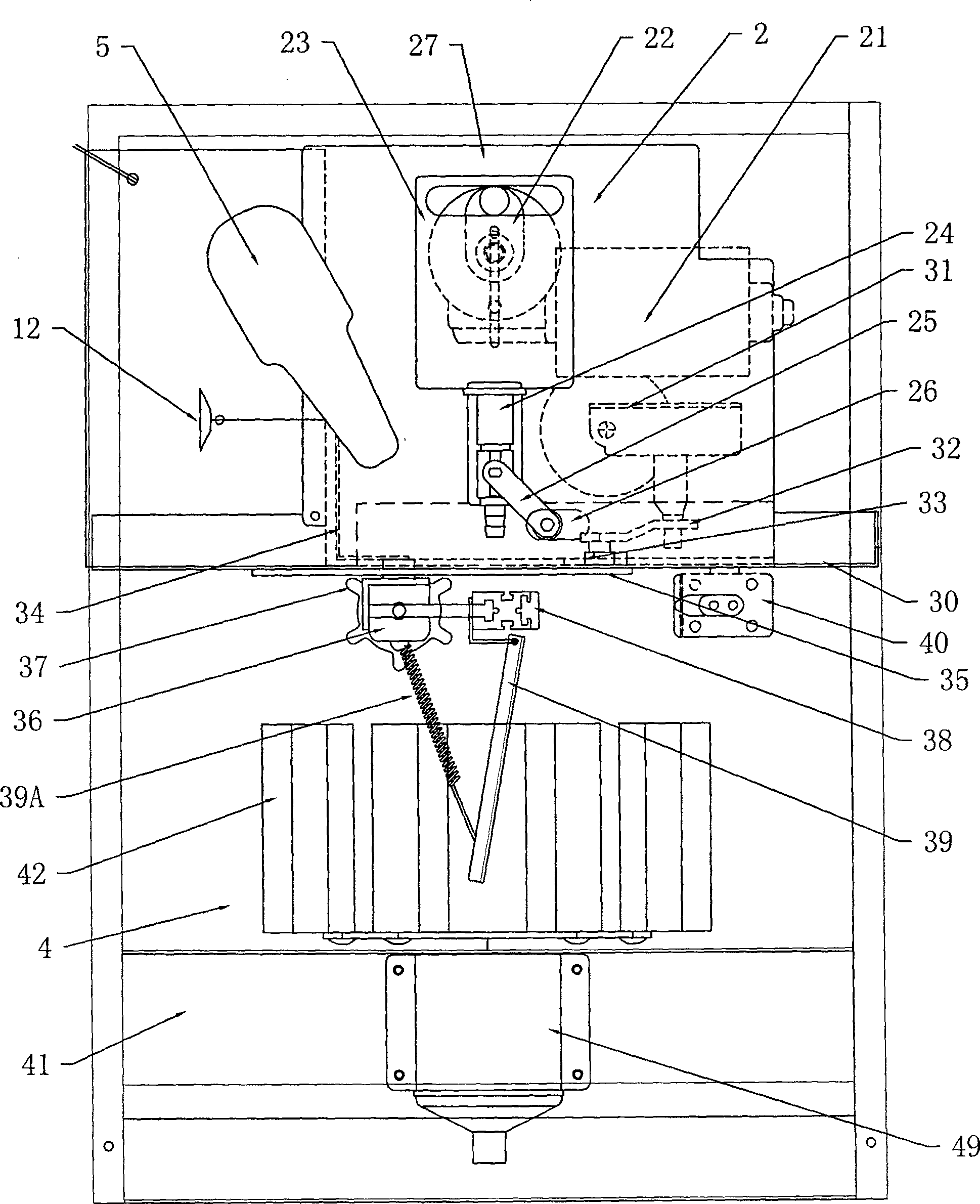

[0026] The packaging assembly includes a rotating mechanism 4, a main control mechanism 3, a bag supply mechanism 1, a filling mechanism 2, a sealing mechanism, a main control bracket 30 arranged in the middle of the cabinet 100 and a rotation mechanism bracket 41 arranged at the bottom of the cabinet 100, ( See figure 2 ,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap