Joint member

A technology for connecting parts and joint grooves, applied in the field of joint parts, can solve the problems of troublesome construction, design problems of joint parts, and inability to become joint grooves, etc., and achieves easy construction, high water interception and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

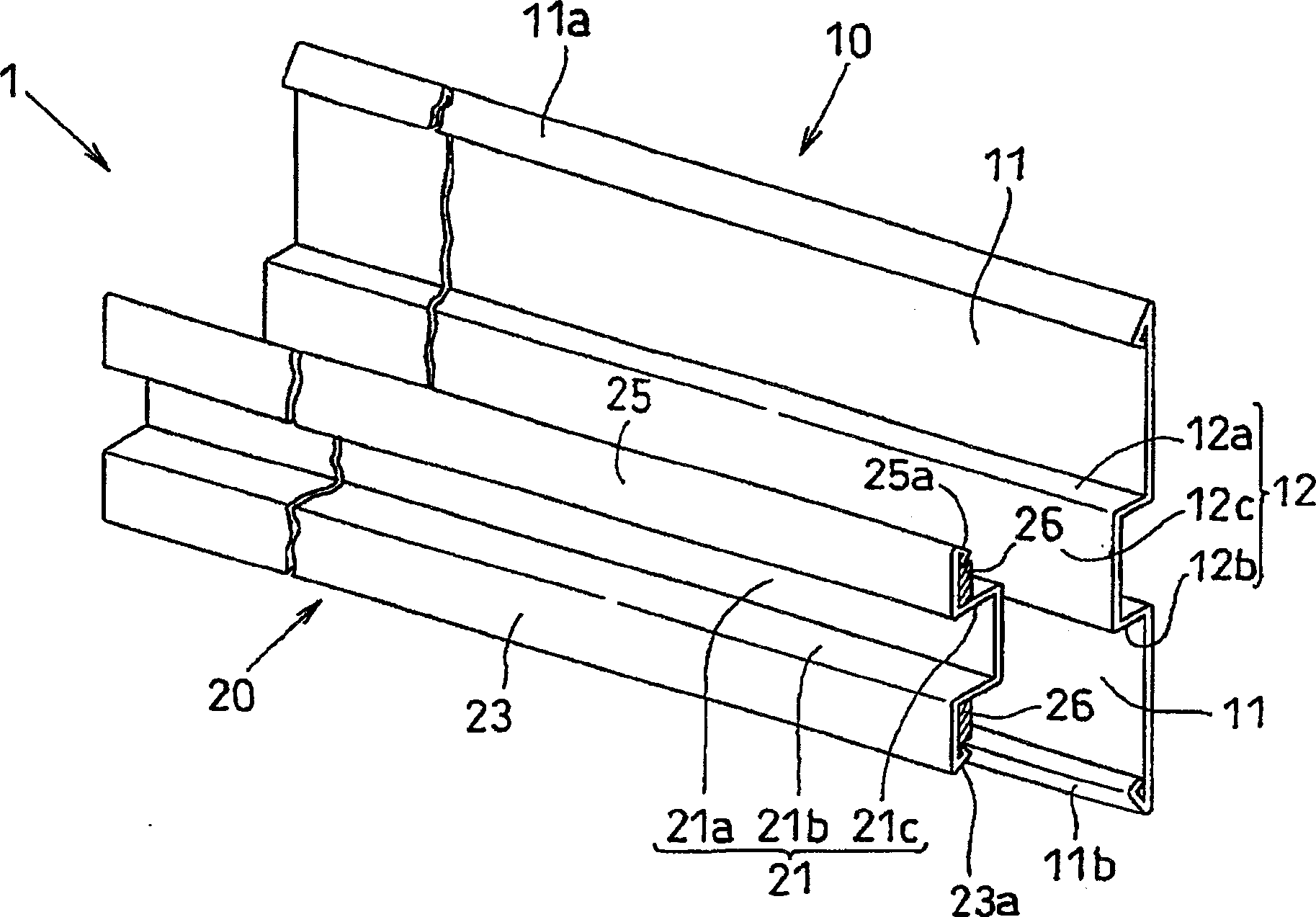

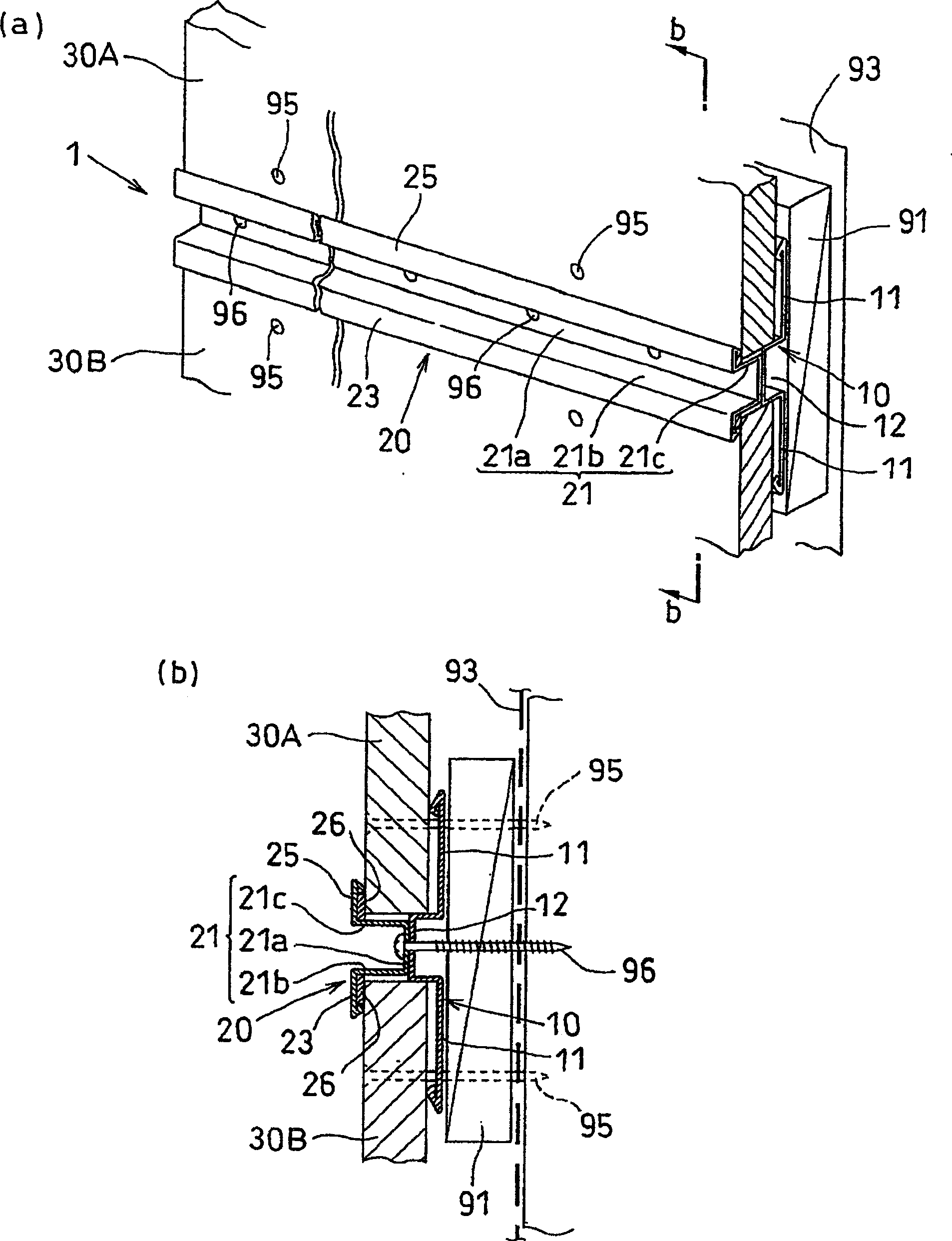

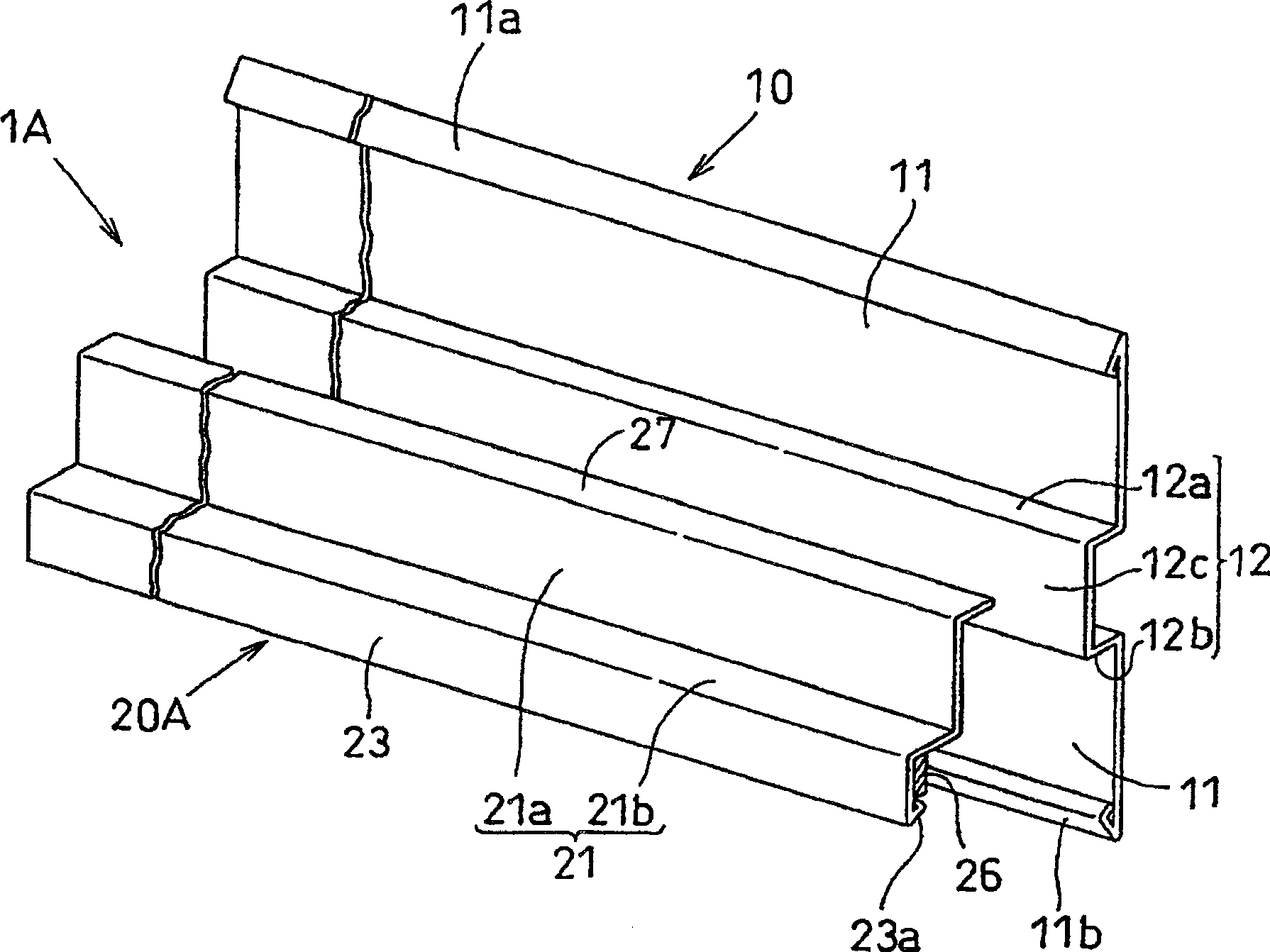

[0031] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 is a perspective view showing a seam according to one embodiment of the present invention; figure 2 a means to use figure 1 A perspective view of the construction configuration of the joint shown; figure 2 b is figure 2 The b—b line cross-section of a.

[0032] exist figure 2 In the shown outer wall construction structure, the outer wall panels 30A, 30B are attached to the horizontal strip 91 by driving nails 95 from the surface side, and the joint material 1 is fixed between the upper and lower outer wall panels 30A, 30B. seam piece 1 by figure 1 The two members shown, ie, the cap connector 10 and the seam cover 20 are constituted, and any one of them is formed by performing sheet metal working on a sheet of steel plate.

[0033] First, the hat connector 10 is composed of a substrate 11 serving as a fixing surface fixed to the horizontal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com