Integrated circuit with self-correcting function, measuring apparatus therefor and parameter self-recording method

A technology of an integrated circuit and a measuring device, applied in the field of parameter programming, can solve the problems of increasing the manufacturing cost of the measuring system, and achieve the effects of saving energy consumption, facilitating application, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

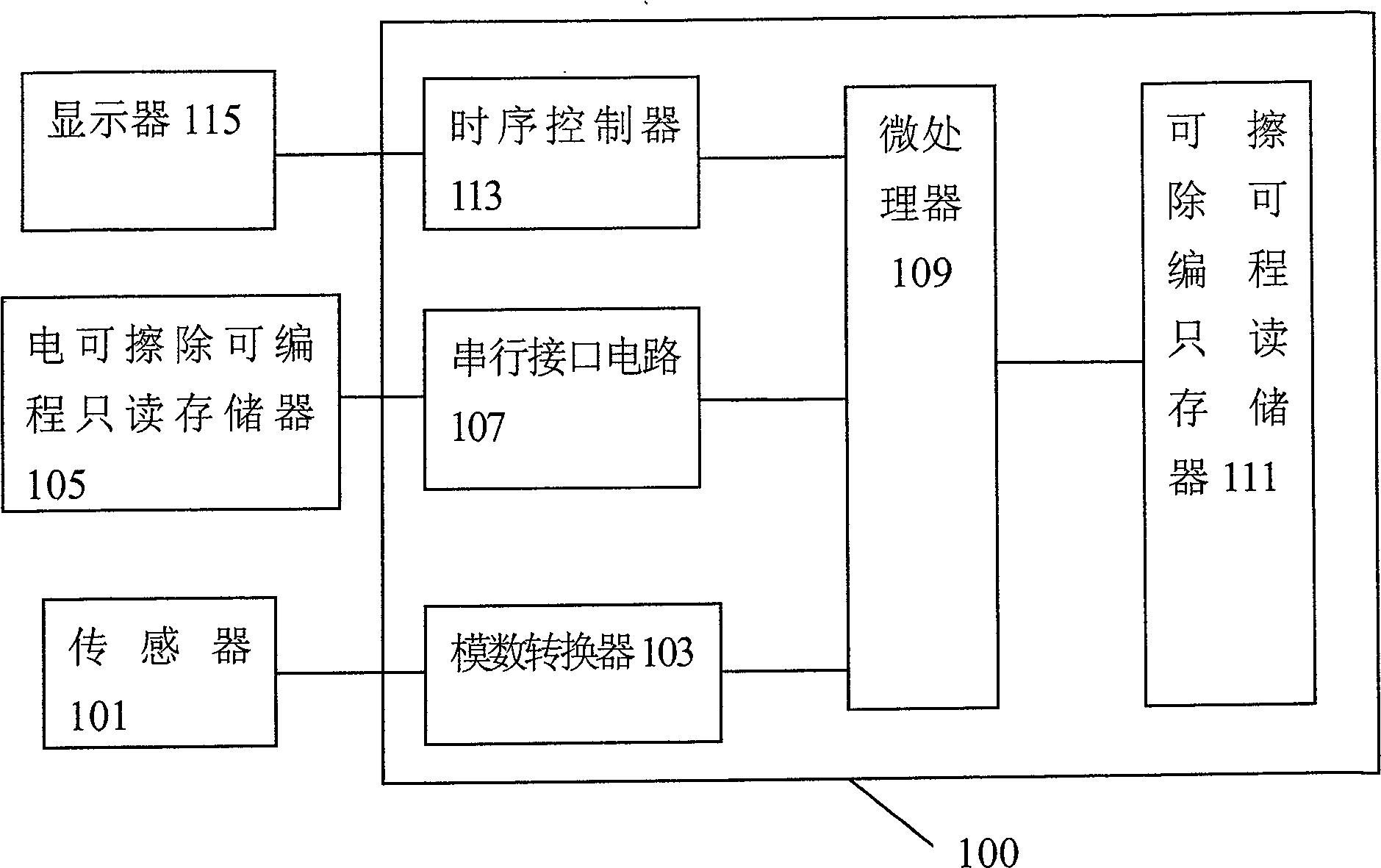

Method used

Image

Examples

Embodiment 1

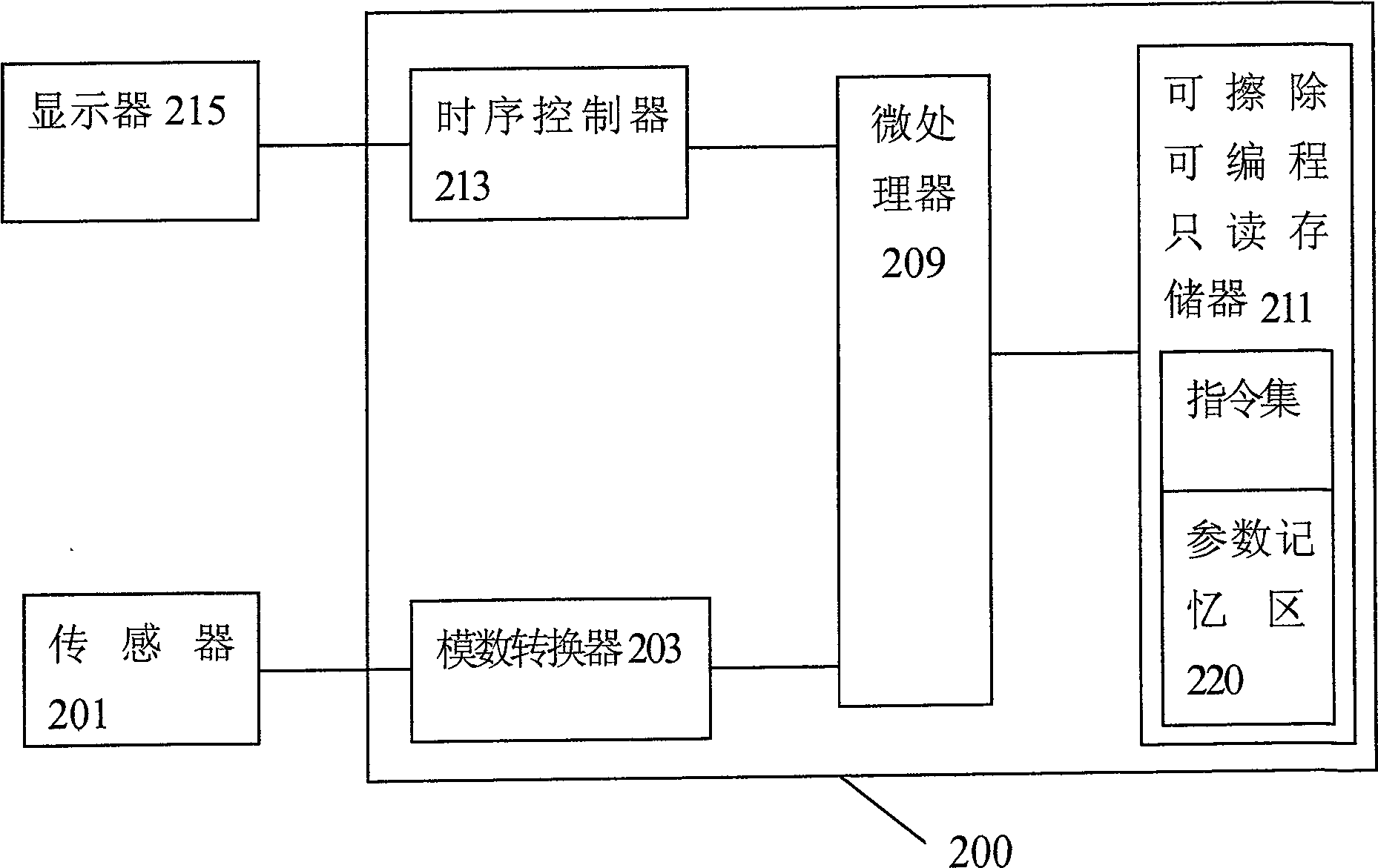

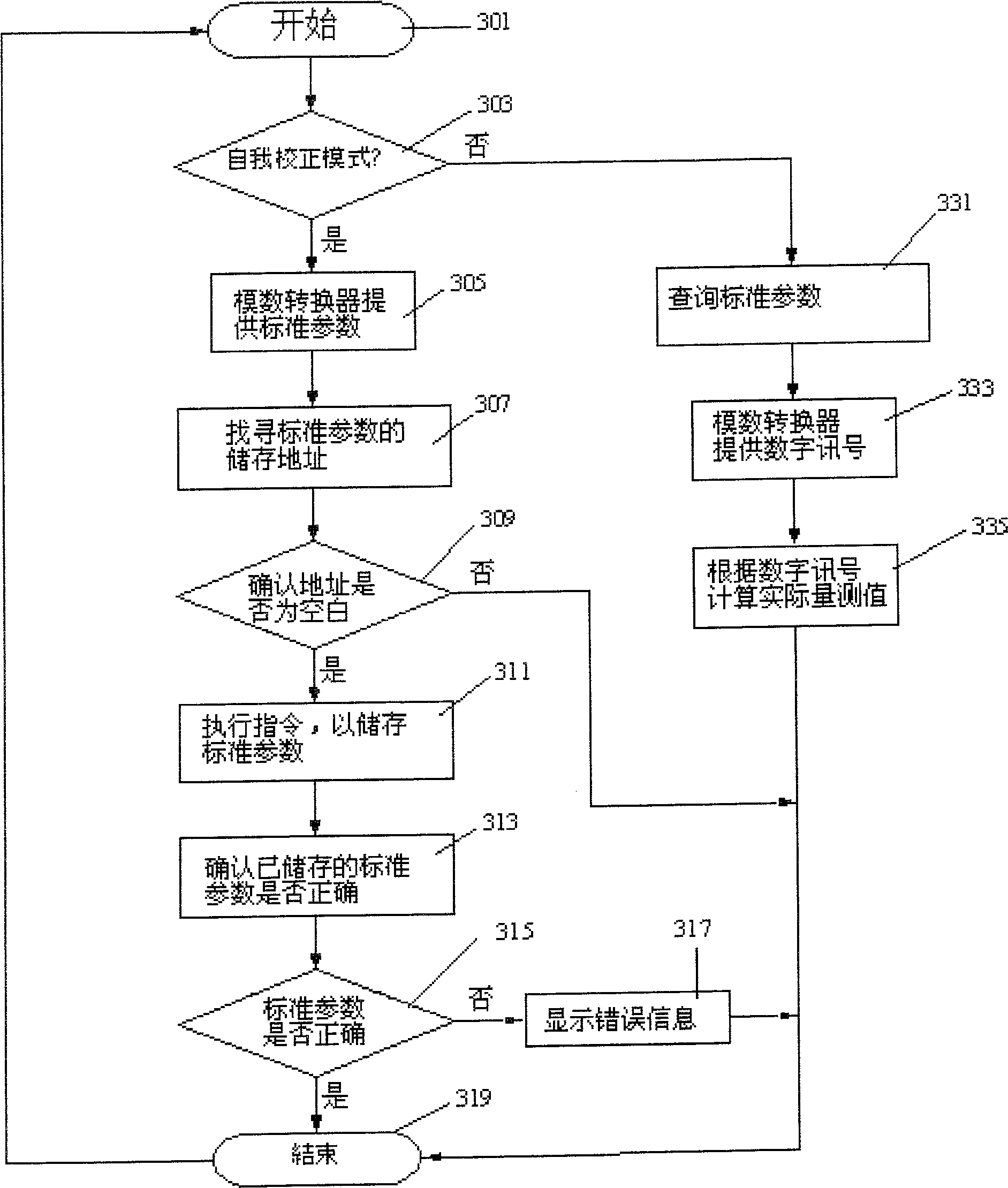

[0033] Embodiment 1: Please refer to Fig. 2, which is a circuit structure diagram showing a measurement device with a built-in one-time programmable memory according to a specific embodiment of the present invention, including an integrated circuit 200, an external sensor 201 and a display 215, and the input of the sensor 201 The measurement signal is sent to the integrated circuit 200 , and the integrated circuit 200 outputs the actual analog quantity of the object to be measured to the display 215 . In the calibration procedure, the sensor 201 contacts the standard measuring object, and outputs a standard signal to the analog-to-digital converter 203 of the integrated circuit 200. The standard signal is an analog signal, which is converted into a digital standard signal by the analog-to-digital converter 203 and input to the microprocessor The device 209 obtains the standard parameters after calculation by the microprocessor 209, and the microprocessor 209 directly stores the...

Embodiment 2

[0040] Example 2: Please refer to Figure 4 As shown, in this example, a charge pump is added to the integrated circuit to directly boost the voltage of the system power supply for writing standard parameters in the self-calibration mode. In the self-calibration mode, when the calibration instruction performs standard parameter programming on the parameter memory area of the programmable memory, the microprocessor sends an enable signal to start the charge pump 216, and selects the conduction charge pump through a switch circuit 217 The output voltage is provided to a programmable memory until the programming of standard parameters is completed. For example: if the integrated circuit power supply is 3 volts, it will generate a voltage of 6 volts by itself after being boosted by the charge pump. In this way, the final system product does not need to be connected with an additional VDD voltage of 5.8 volts, and the external voltage source can be reduced when programming the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com