Method for preparing flower fragrance flavor tea

A technology for flavored tea and floral aroma, applied in the direction of tea treatment before extraction, can solve the problems of low concentration, long production cycle, failure to meet quality requirements, etc., to improve the utilization rate of raw materials, reduce the loss of floral aroma and shorten the time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

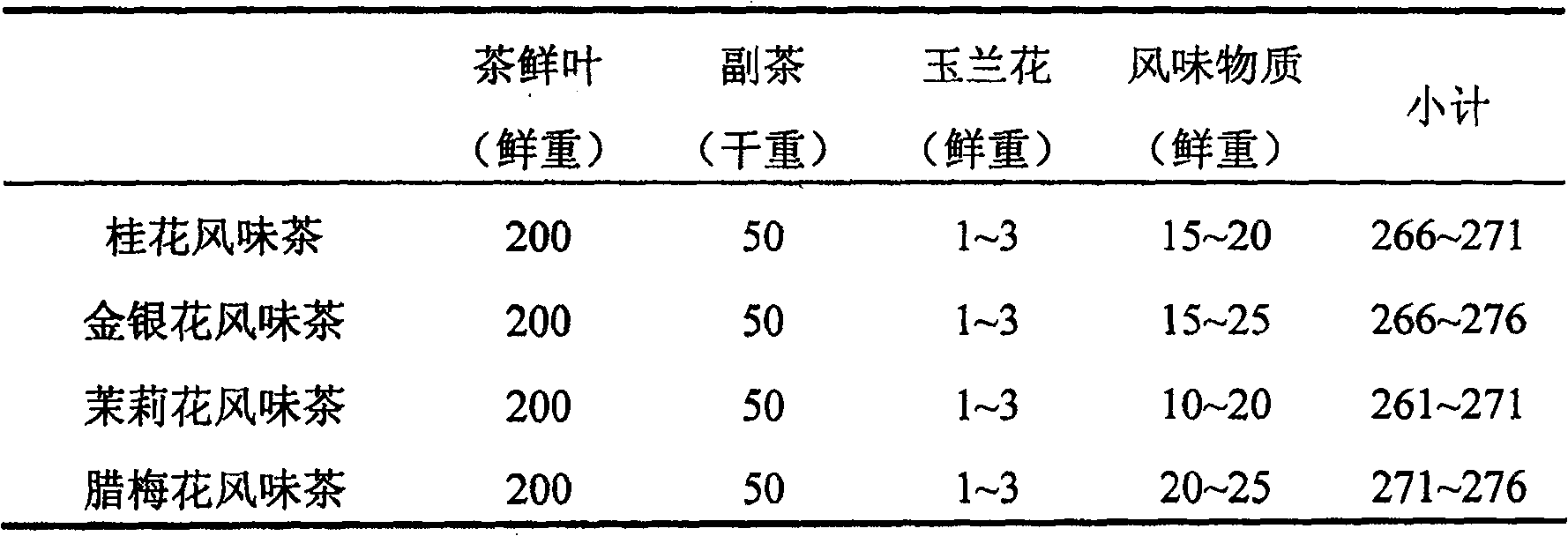

[0024] Embodiment 1: sweet-scented osmanthus flavor tea

[0025] A preparation method of sweet-scented osmanthus flavor tea, is characterized in that: it puts magnolia flower and auxiliary tea together, carries out auxiliary tea fragrance (usually all will remove magnolia); After the auxiliary tea is mixed evenly (the weight ratio of the fresh tea leaves before treatment and the aroma-absorbed auxiliary tea is 8:2), the LTP machine is used to hammer and cut, the granulator is used for preliminary granulation, or the plane circular sieve machine is used for re-granulation , made into granular tea and baked until fully dry; then flavored with fresh sweet-scented osmanthus, and controlled within 9% of the water content, to obtain the finished tea.

[0026] In the above method, the fragrance absorption of the auxiliary tea refers to adding magnolia flowers according to 2% of the weight of the auxiliary tea and blending and scenting for 18 hours; Scenting, the scenting time is 10 ...

Embodiment 2

[0027] Embodiment 2: honeysuckle flavor tea

[0028] A kind of honeysuckle-flavored tea, which blends magnolia flowers with secondary tea to inhale the aroma of the secondary tea; after mixing the tea leaves that have been conventionally finished after 13 hours of stacking with the secondary tea after the aroma absorption (the fresh tea leaves before processing and the secondary tea) The weight ratio of the auxiliary tea after inhalation is 8:2), using LTP machine hammer cutting, granulation machine preliminary granulation or re-granulation with flat circular sieve machine to make granulated tea and bake it until it is dry enough; then mix it with fresh The honeysuckle is used for flavor and fragrance absorption, and the water content is controlled within 8% to obtain finished tea.

[0029] In this example, the fragrance absorption of the secondary tea refers to adding magnolia flowers according to 3% of the weight of the secondary tea and blending and scenting for 16 hours; ...

Embodiment 3

[0030] Embodiment 3: wintersweet flavor tea

[0031] A preparation method of wintersweet flavor tea, which comprises taking fresh tea leaves, dried side tea, magnolia flowers and wintersweet flowers in a weight ratio of 200:50:1:25; mixing the taken side tea with the taken magnolia flowers, and carrying out 17 hours of aroma absorption treatment; the fresh tea leaves were steamed, mixed with the secondary tea after aroma absorption, hammered, granulated, processed into granular tea, and dried to a water content of less than 5%; then added Take wintersweet flowers for flavor and fragrance absorption, and the basement time is 11 hours, so that the water content of the final product is controlled at about 6%, and the finished tea is obtained.

[0032] In this example, the hammer cutting is carried out by the LTP hammer cutting machine, and the granulation is carried out by the granulator for preliminary granulation or the flat circular screen machine for re-granulation.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com