Boron-ore-slurry solid-liquid separation method

A process method and a liquid separation technology, applied in the field of boron beneficiation, can solve the problems of large floor area, low production efficiency, and environmental pollution, and achieve the effects of saving floor area, improving production efficiency, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

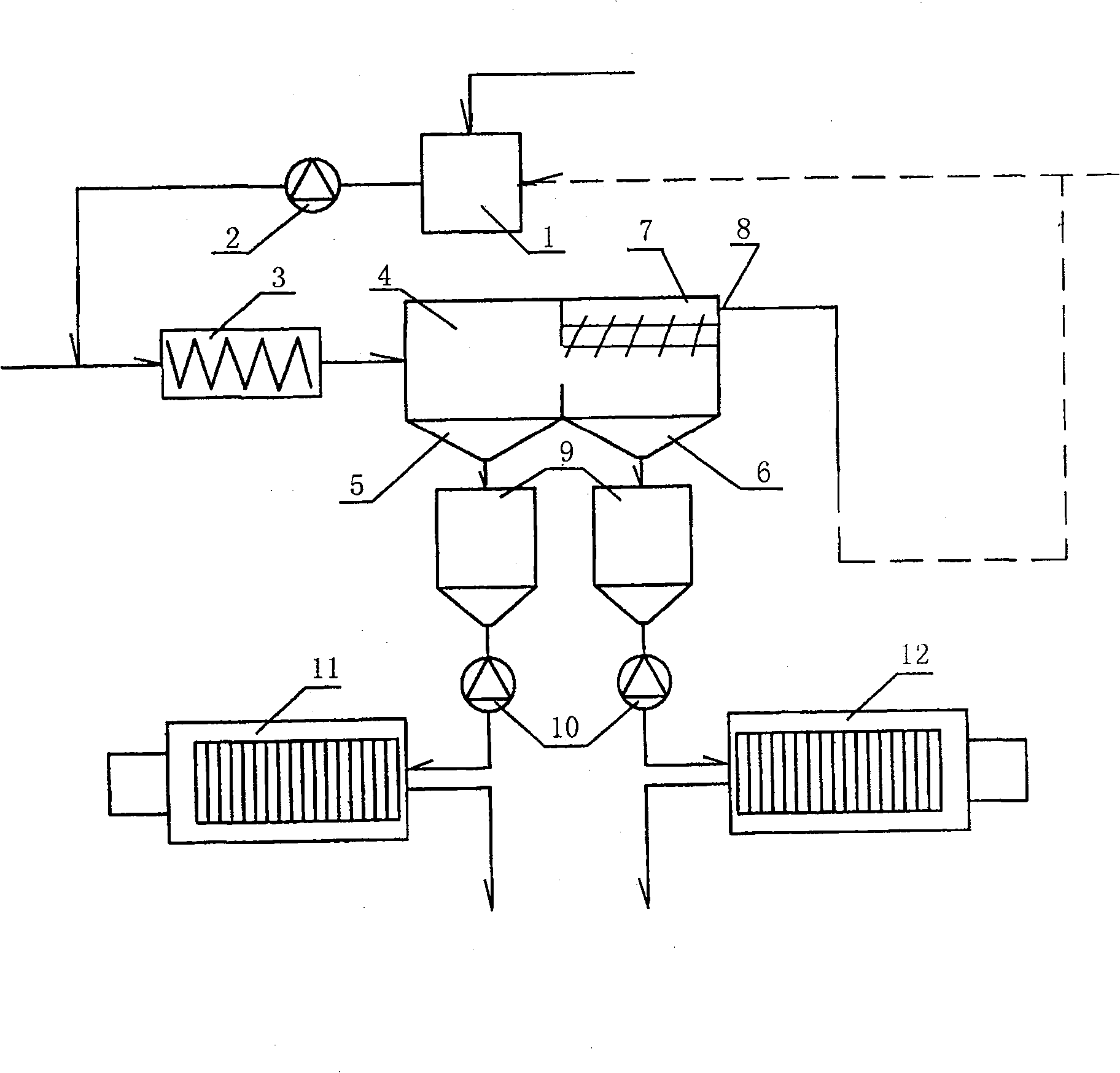

[0008] Example 1: In the boron ore slurry after magnetic separation of iron powder, usually the dry basis boron powder accounts for 5-20% of the total weight of the boron ore slurry. Add polyacrylamide as a flocculant, the amount is 0.5‰ of the dry basis weight of the boron pulp, add water and stir in the flocculant dissolving tank 1 to make a flocculant solution, the flocculant solution is mixed with the boron pulp according to the solute ratio through the metering pump 2, After being mixed evenly by the mixer 3, some of the fine boron powder particles in the boron ore slurry are aggregated into larger flocculation groups. The flocculation process is completed instantly in the mixer 3. The property is not good, which will affect the precipitation. It is better at normal temperature. Then the mixed solution is transported to the concentration tank 4 for precipitation. A slant plate 7 is arranged on the upper part of the secondary tapered groove, and 3-5 tapered grooves can als...

example 2

[0009] Example 2: Add a flocculant to the boron pulp, the amount is 2‰ of the dry weight of the boron pulp, add water and stir to make a flocculant solution, enter the sediment in the two conical tanks 5 and 6, settle for 30 minutes, and other Technological process is identical with example 1.

example 3

[0010] Example 3: The boron ore slurry after magnetic separation of iron powder is transported to the concentration tank 4 for precipitation. At a temperature that ensures the free flow of the boron ore slurry, such as about 15°C, the heavier particles in the boron ore slurry settle in the first-stage conical tank 5 Inside, the lighter particles settle in the secondary conical groove 6, and the sediment settles in each conical groove for 2 hours, and then is sent to the filter press to filter respectively, and other processes are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com