Multi-spindle head replacement type machine tool

A technology of processing tools and multi-axis heads, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems that it is difficult to realize the high-speed rotation of the tool and the high-speed rotation of the output shaft 206, so as to improve the processing performance, The effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] Exemplary embodiments of the present invention will be described with reference to the accompanying drawings.

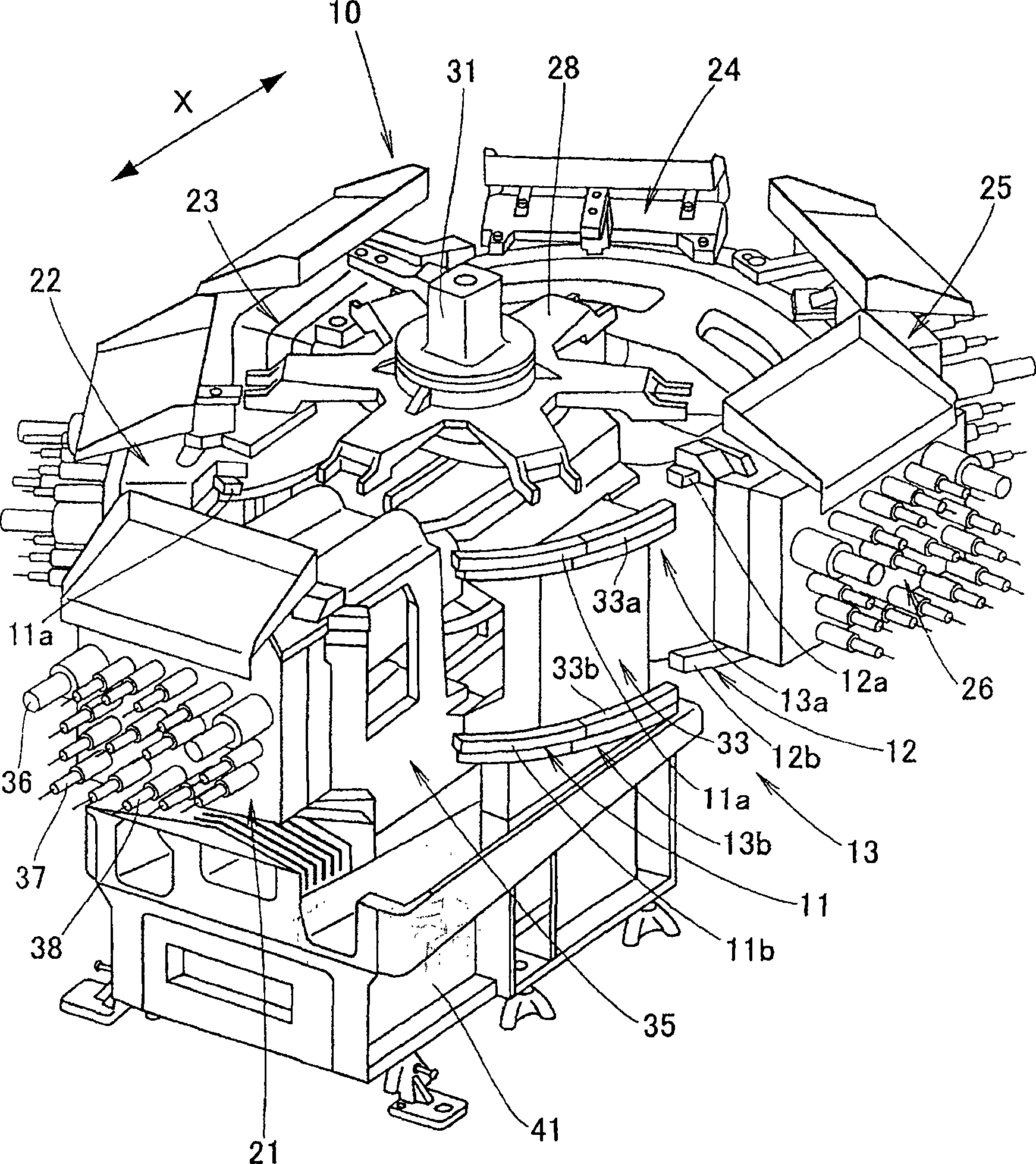

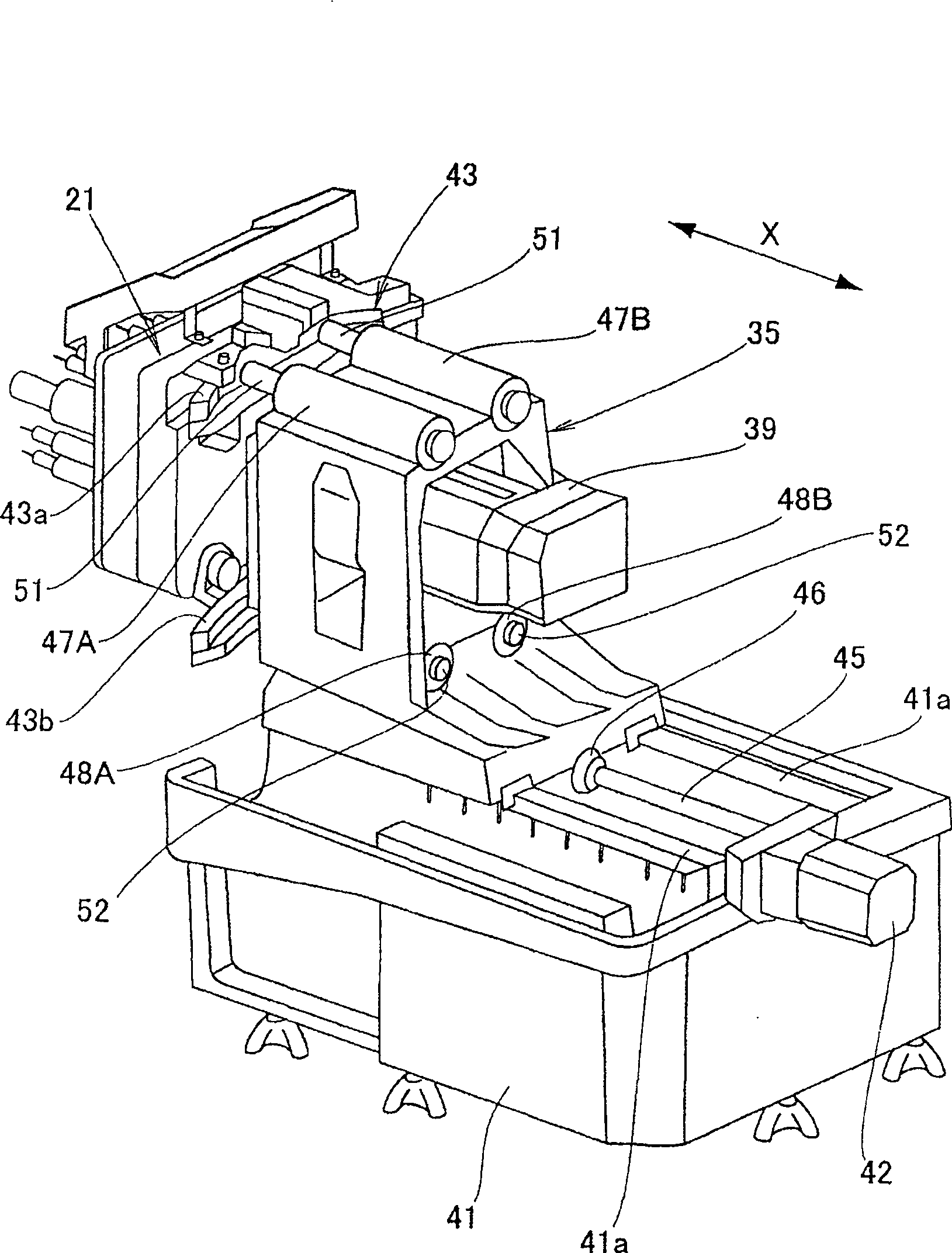

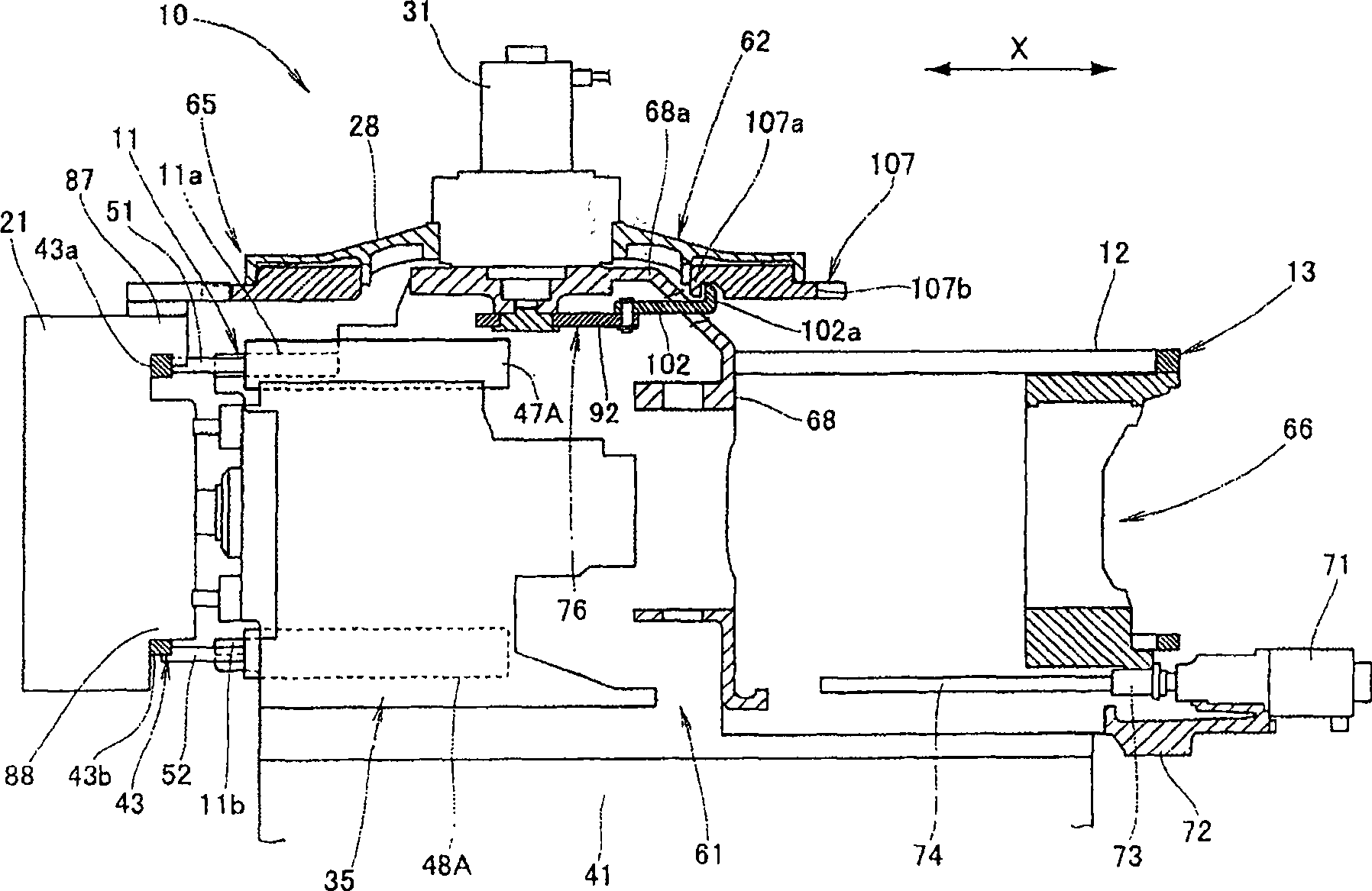

[0118] Preferably, the drawings are viewed based on the direction of the reference marks. figure 1 is a perspective view of a multi-spindle replaceable machining tool according to an embodiment of the present invention. In this multi-spindle head replaceable machining tool 10, a plurality of multi-spindle heads (referred to as “combined heads”) 21 to 26 are movably mounted to an annular rail 13, which can be divided into a first stationary rail 11 along the X-axis direction. and the second geostationary orbit 12. The first stationary rail 11 comprises an upper first stationary rail 11a and a lower first stationary rail 11b placed below the upper first stationary rail 11a, and the second stationary rail 12 comprises an upper second stationary rail 12a and a lower first stationary rail 11b placed below the upper first stationary rail 11a. The lower second stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com