Spraying chamber

A technology of spraying booths and coating booths, applied in the field of spraying booths, which can solve problems such as long distances, large-scale painting booths, poor coating, etc., and achieve the effect of maintaining the coating environment, eliminating troubles, and improving operation interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

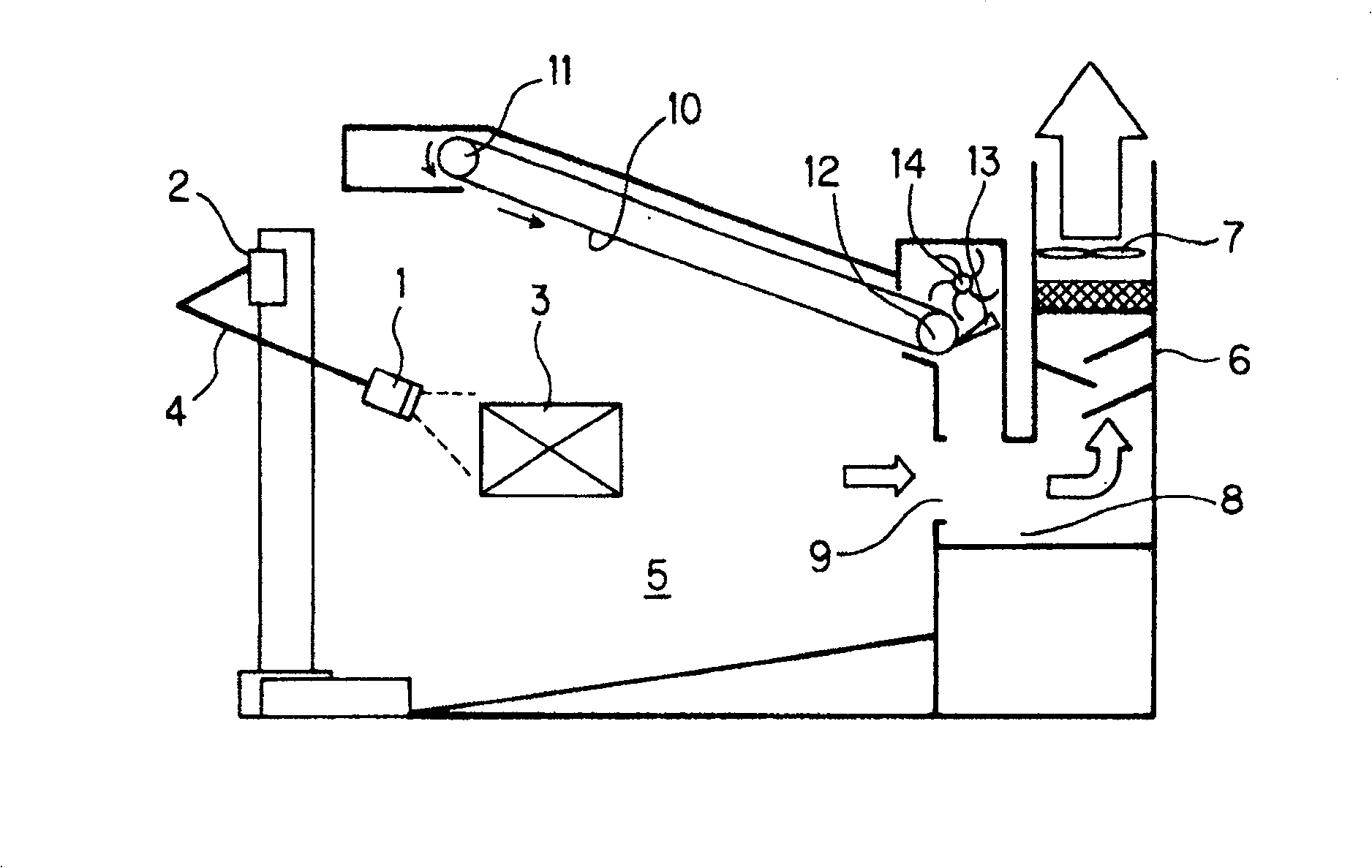

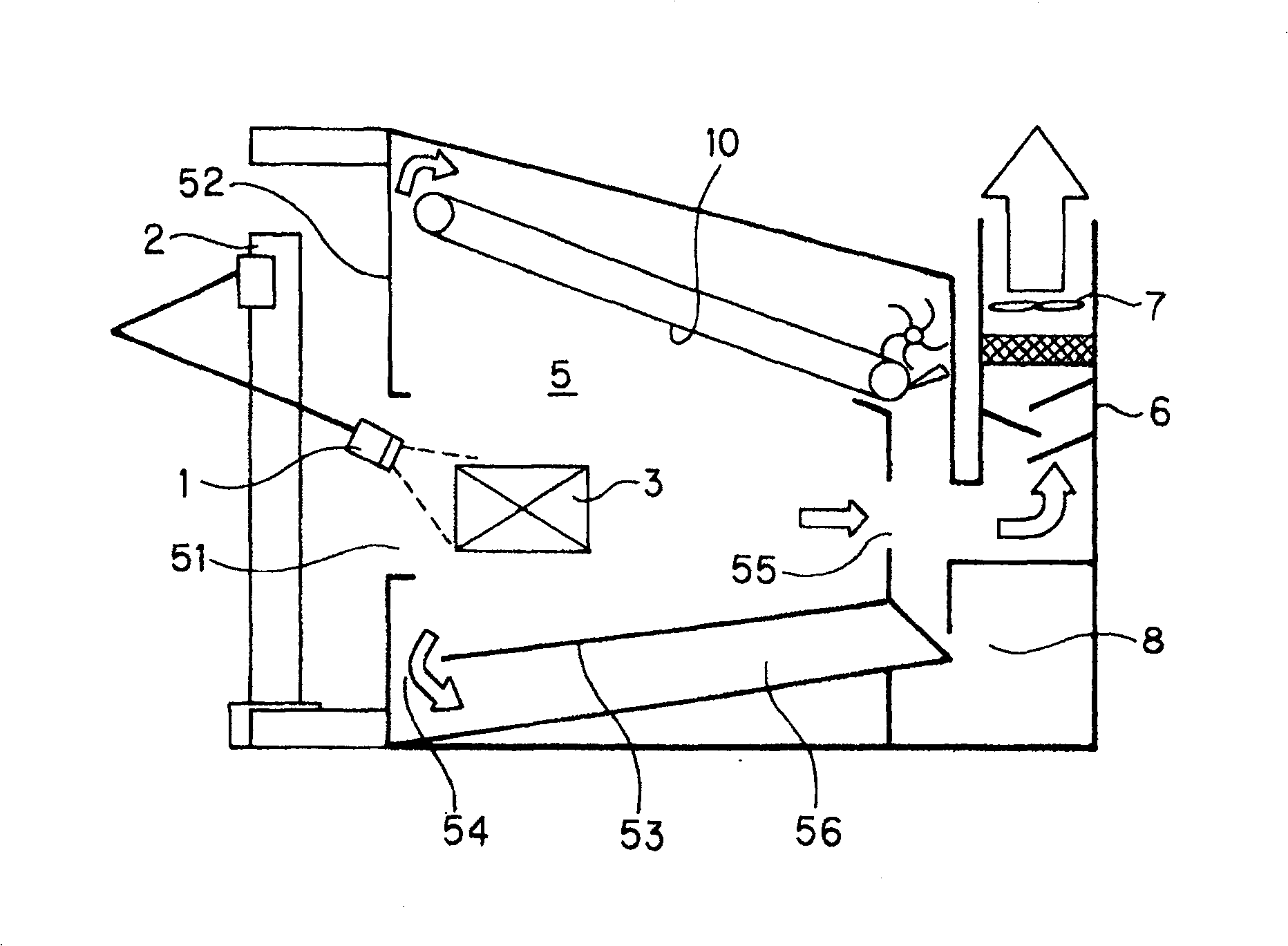

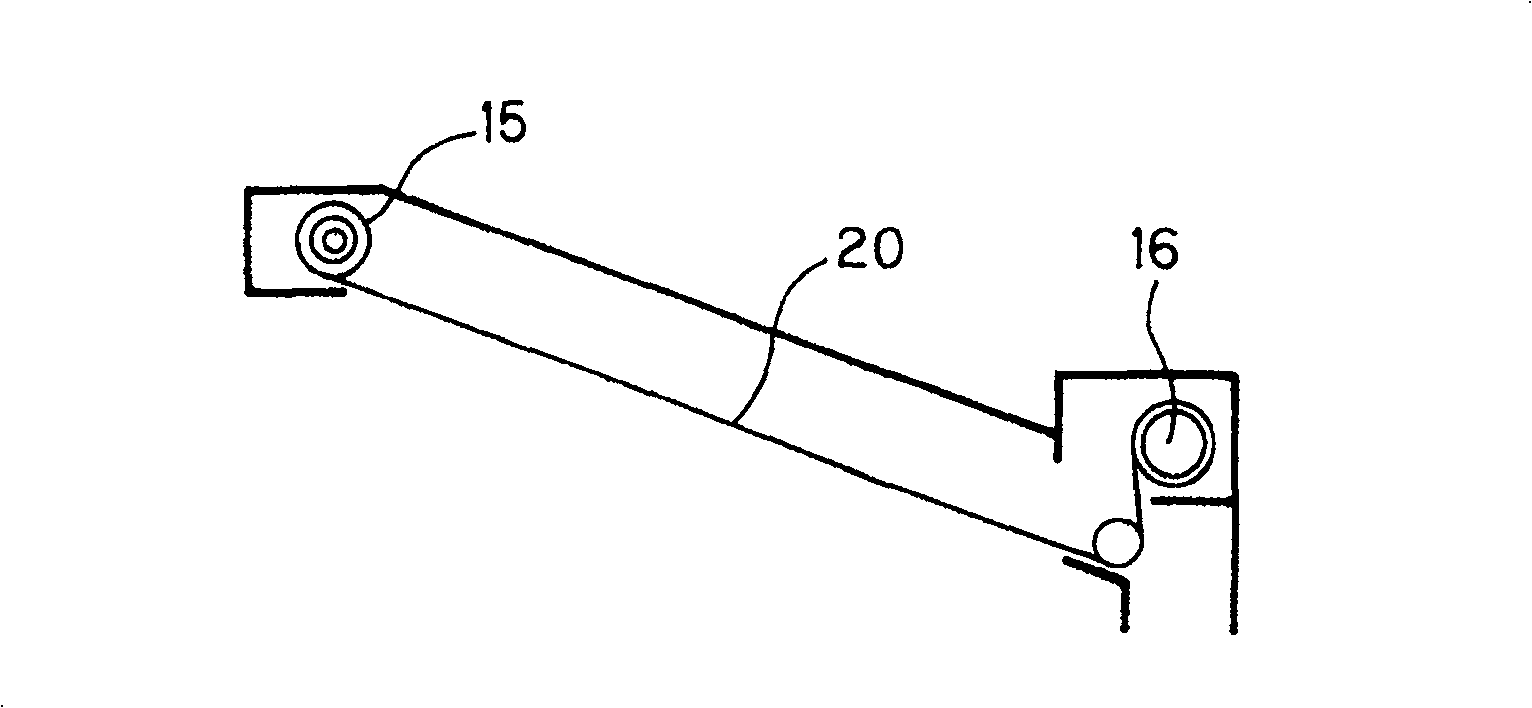

[0037] The specific content when implementing the present invention will be described below with reference to the accompanying drawings. figure 1 It is a schematic configuration diagram showing an example of a painting booth for carrying out the present invention. In this example, the spray gun 1 is an automatic spray gun, and spraying is performed automatically by compressed air, and usually, spraying is controlled by compressed air from a solenoid valve operated by a signal from a control device. The spray gun 1 is mounted on a painting robot 2 as an automatic painting device, and the painting position, direction, etc. are controlled and operated to paint the object 3 to be painted. Usually, the painting robot 2 can not only move up and down, left and right, and front and back by the arm 4, but also can make the spray gun 1 freely carry out the spraying operation by means of the angle change and rotary operation of the installation part of the spray gun 1. The signal of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com