Wind power dewatering low temperature drying method and wind power dewatering low temperature drying machine thereof

A dryer, low temperature technology, applied in progressive dryers, dryers, drying of solid materials, etc., can solve the problems of large investment in production facilities, high energy consumption, low efficiency, etc., to achieve small footprint and high flow rate. , the effect of simple process facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

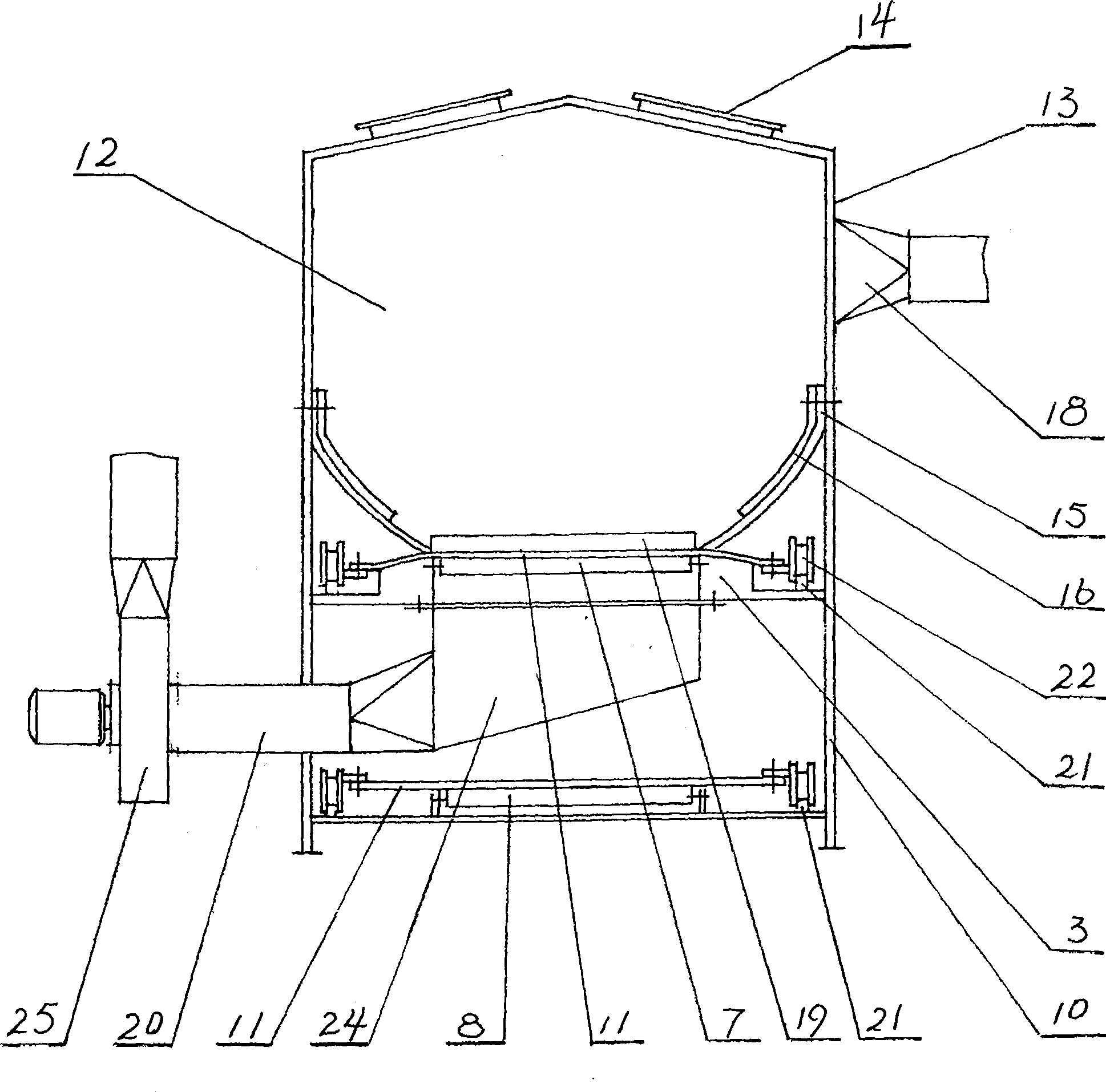

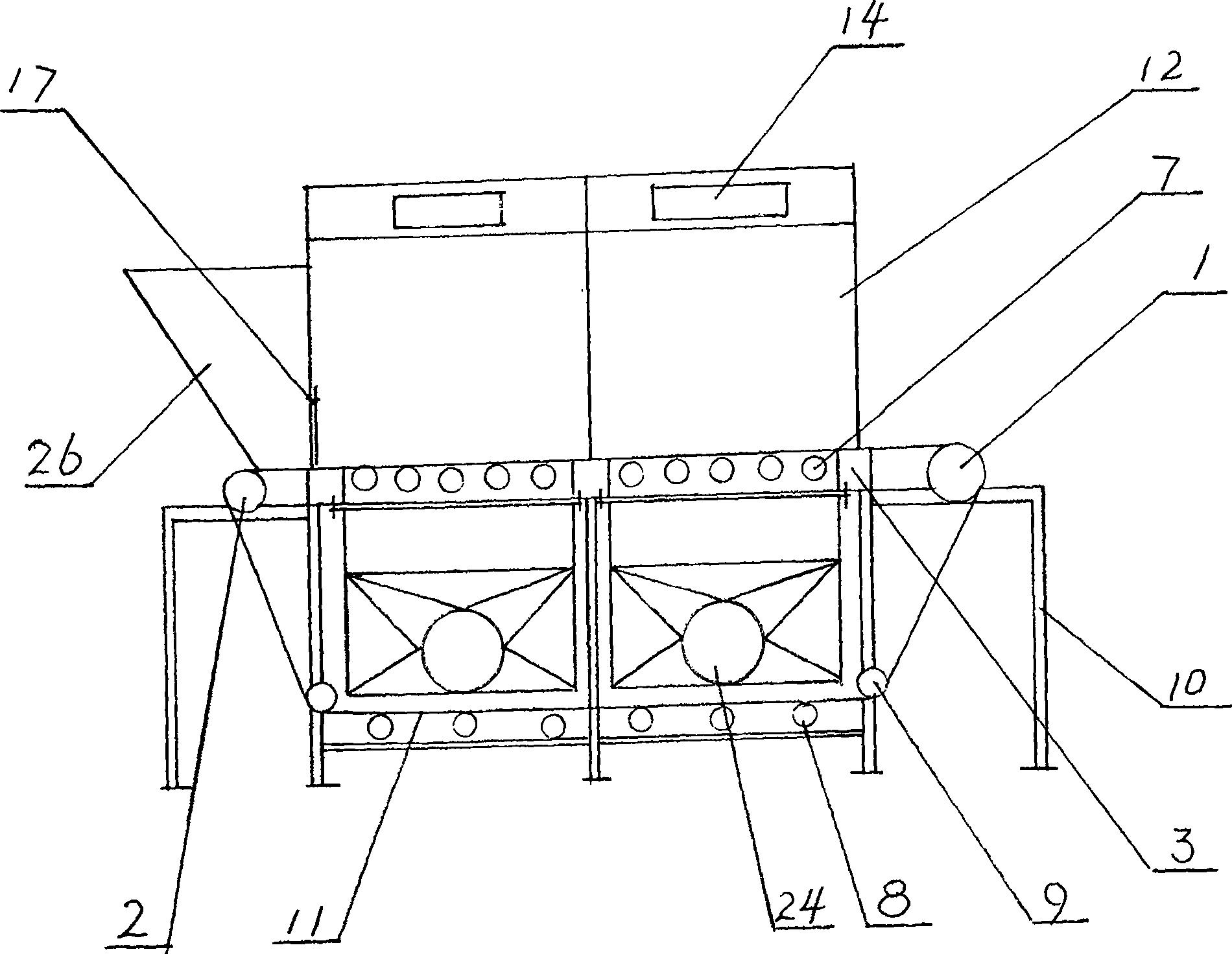

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

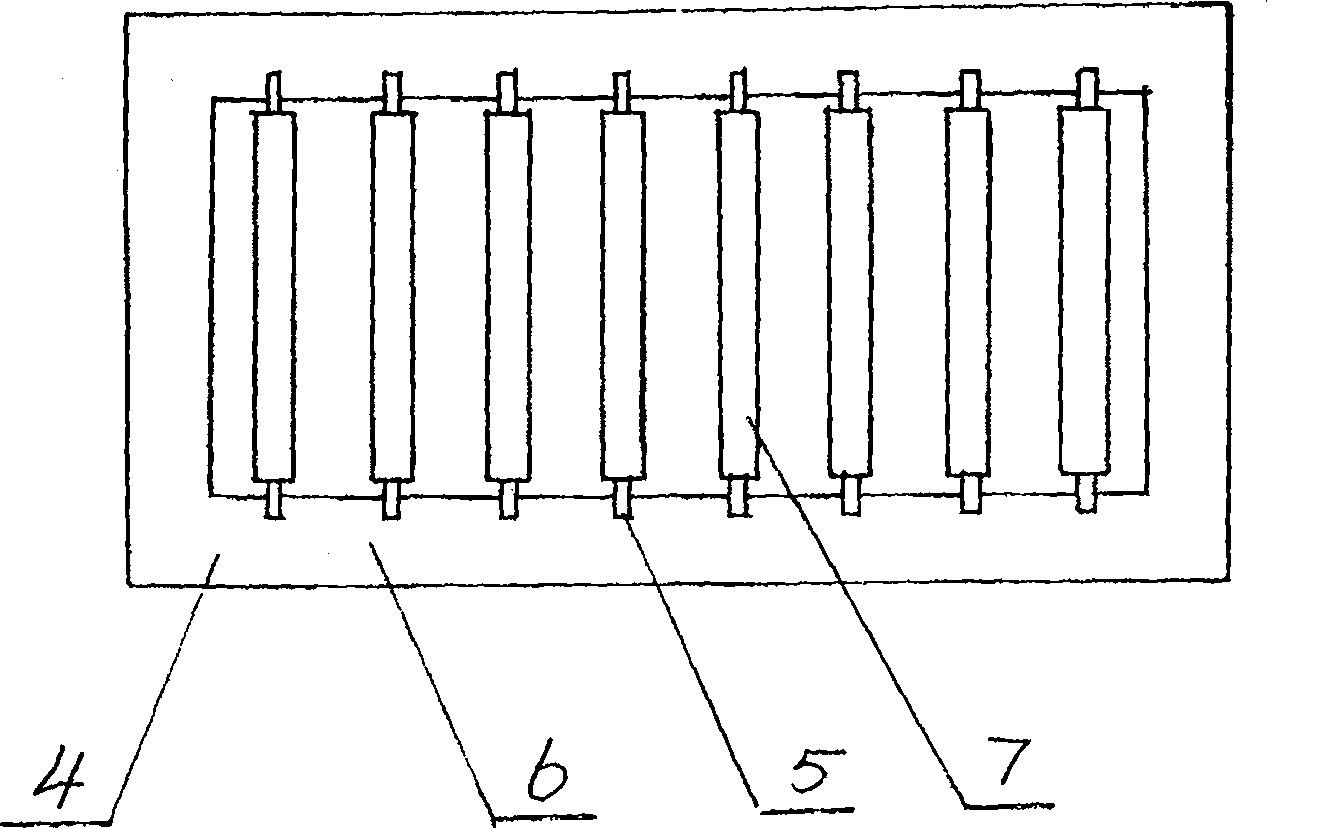

[0023] The air dehydration low-temperature dryer of the present invention comprises: a belt filter, a filter support frame 10 , an upper wind chamber 12 , a lower wind chamber 24 , and a blower fan 25 . An upper air chamber 12 is provided on the top of the filter support frame 10, and a lower air chamber 24 is provided on the bottom of the filter support frame 10,

[0024] The belt filter is installed on the support frame 10 of the filter, and the head wheel 1 and the tail wheel 2 are arranged on the upper part of the support frame, and the lower supporting roller 8, the reversing drum 9 and the track 21 are arranged on the lower part of the support frame.

[0025] The two ends of the head wheel 1 are provided with chain teeth and matched with the plate chain, the plate chain 22 and the filter heat-resistant belt 11 are connected by bolts, and the head wheel drives the plate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com