Drying equipment for clam essence preparation and drying method of clam essence preparation

A drying equipment and drying technology, applied in the direction of drying solid materials, dry cargo handling, drying chamber/container, etc., can solve problems such as uneven drying inside and outside, prolonged drying time, and less function of the dryer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

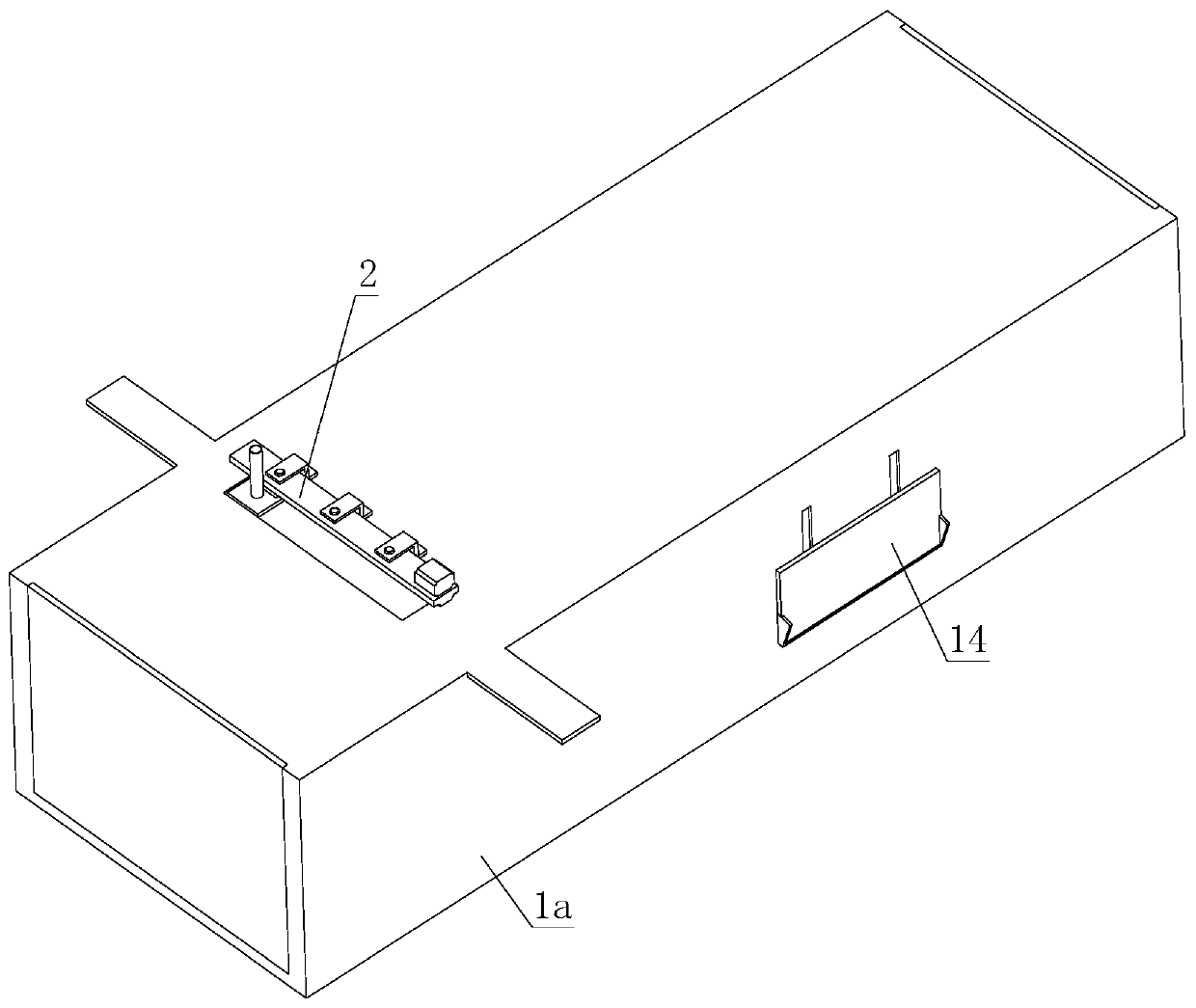

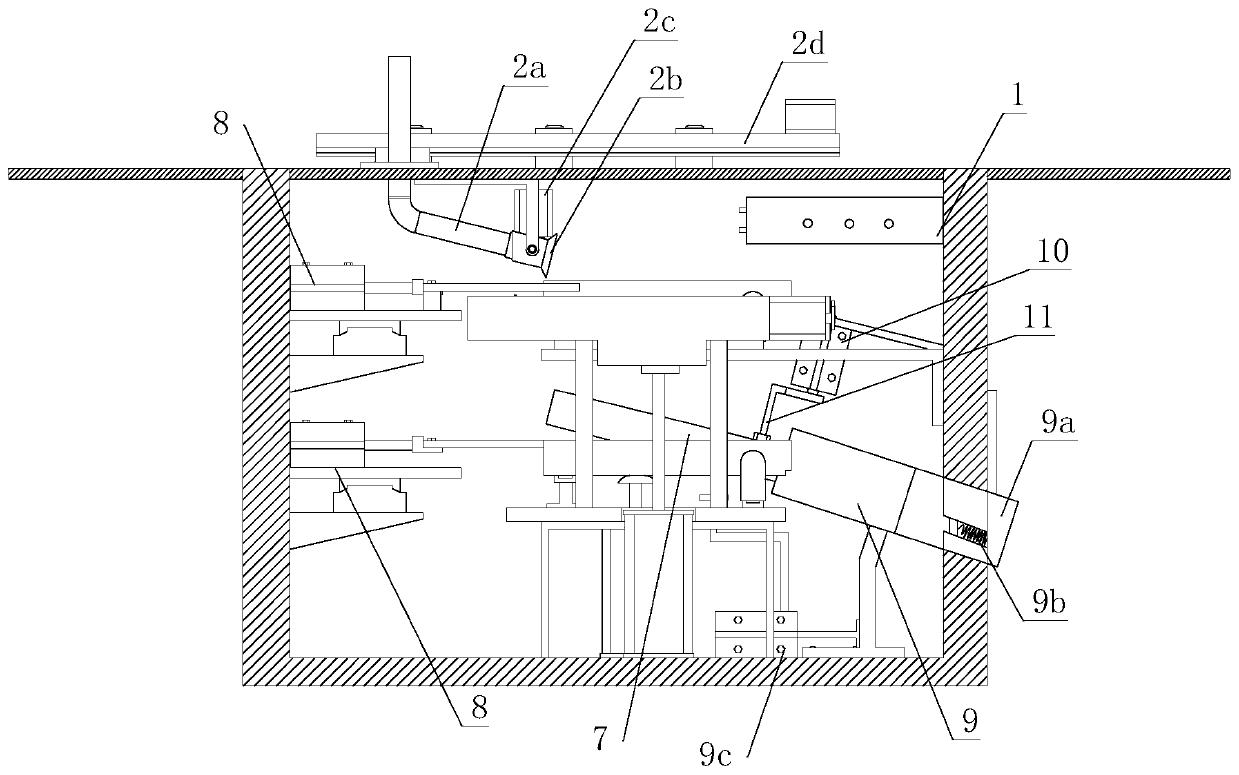

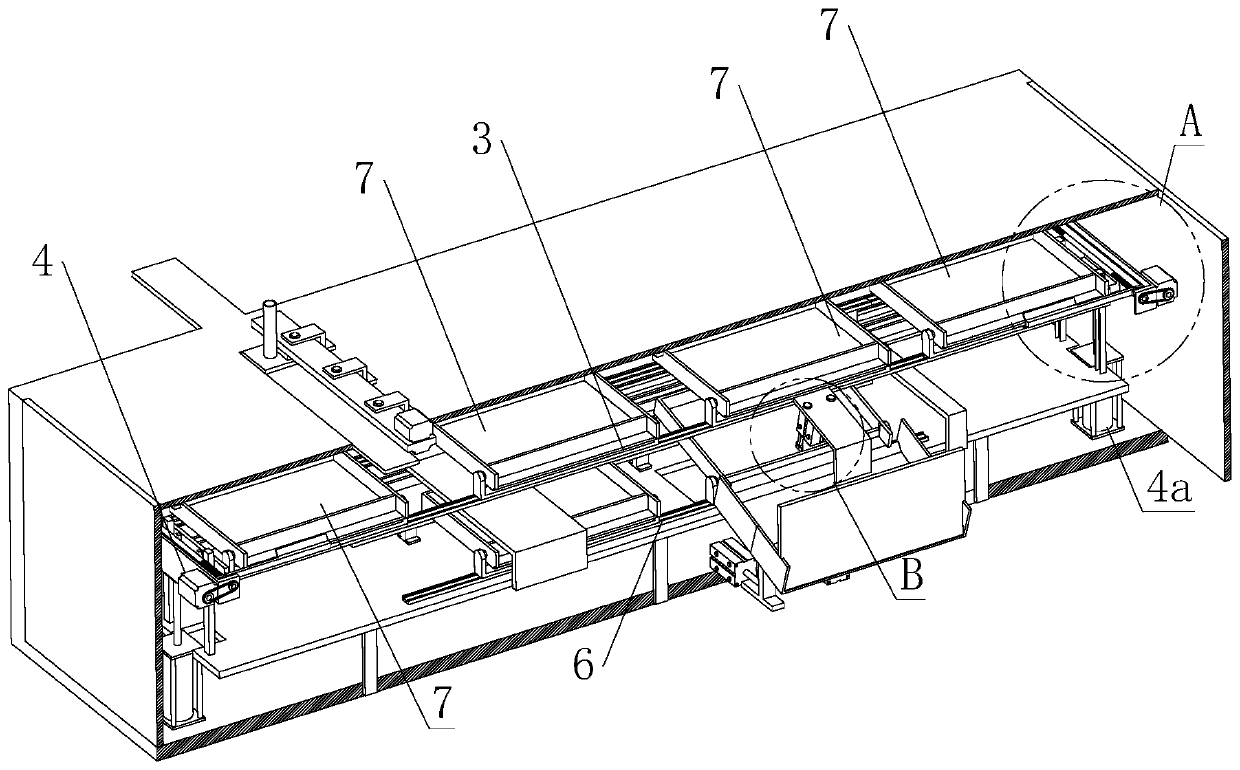

[0050] refer to Figure 1 to Figure 13 Shown a kind of drying equipment that is used for clam crystal preparation, comprises far-infrared ray drier 1, drying cabinet 1a, feeding device 2 and structure identical upper layer drying track 3 and lower floor transfer track 6, far-infrared ray drier 1 is set In the drying box 1a, and its launch end corresponds to the upper drying track 3, the two ends of the upper drying track 3 are respectively provided with a lifting transfer device 4, and the same side of the upper drying track 3 and the lower transfer track 6 are respectively provided with a Material shifting device 8, the other side of the lower transfer track 6 is provided with a material receiving device, the receiving device corresponds to the front side of the drying box 1a, the lower transfer track 6 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com