Diversion device used in turbomachine having adjustable nozzle

A diversion device, turbine technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems that affect the reliability of use, leakage, and small gaps between rotating parts, so as to improve the reliability of use and prevent leakage Good, the effect of preventing gap leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

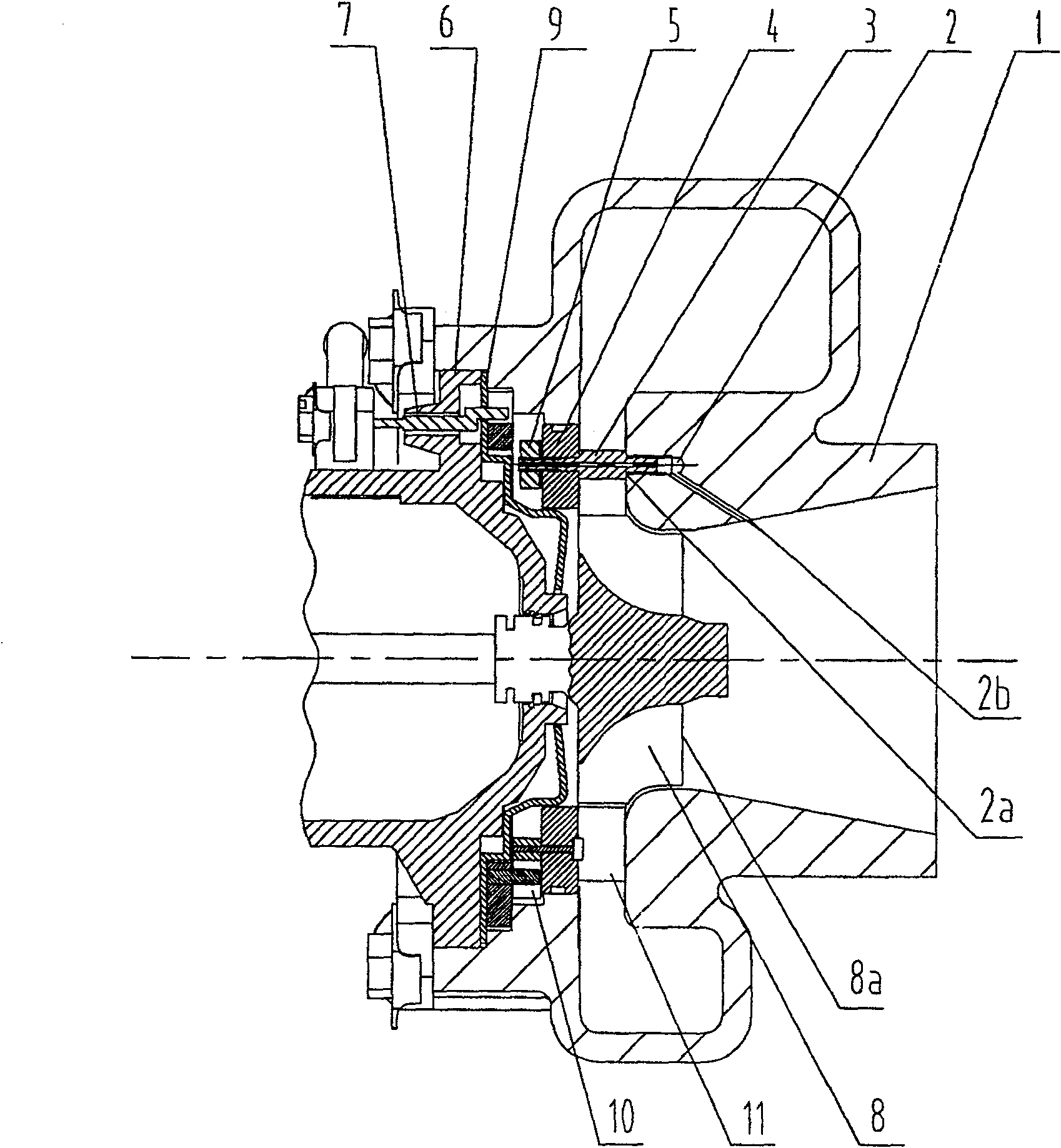

[0017] Example: see figure 1 , figure 2 , a flow guide device for a single-stage turbine with an adjustable nozzle, characterized in that: the flow guide device includes a flow guide channel 2 and a positioning tube 3, wherein one end of the positioning tube 3 is connected to the guide channel The diversion inlet 2a of 2 is connected.

[0018] Described deflector is arranged on the inner side of air outlet 1a of the turbine shell 1 of turbomachine and the driving mechanism 10 of some nozzle vanes 11 on the circumference of the jet passage in the turbine shell 1, consists of turbine shell 1, bearing shell 6, partition Between the annular cavity formed by the connection between the plate 4 and the heat shield 9 .

[0019] The guide channel 2 is arranged in the shell of the turbine shell 1, the guide inlet 2a is set on the outer wall of the jet channel of the turbine shell 1, and the guide outlet 2b is set on the The inner side surface of the air outlet 1a of the turbine shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com