Air humidity removing device

A humidity and gas technology, which is applied in the field of gas humidity removal devices, can solve problems such as system shutdown, performance cannot be improved, and dehumidification effect is discounted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

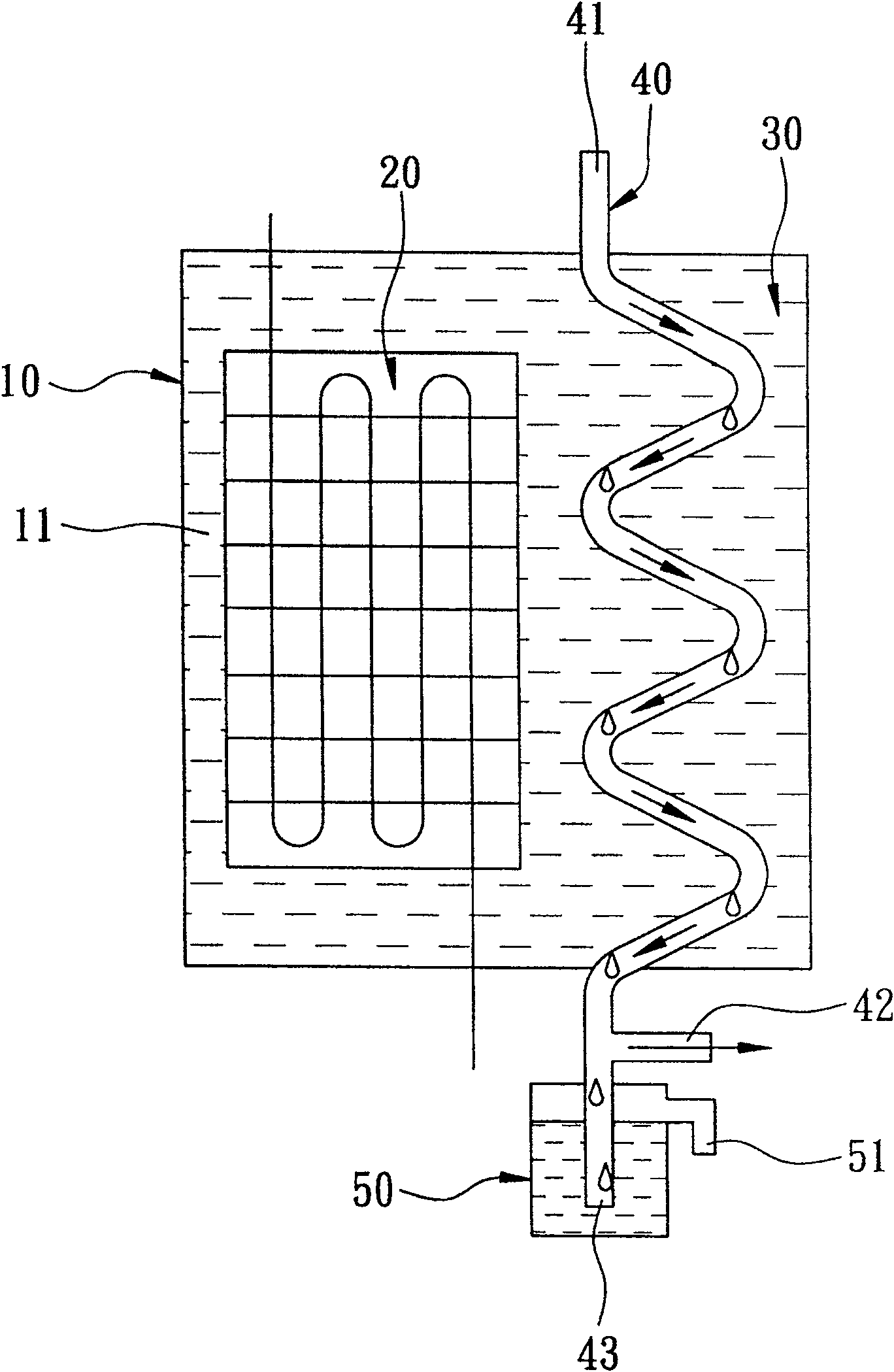

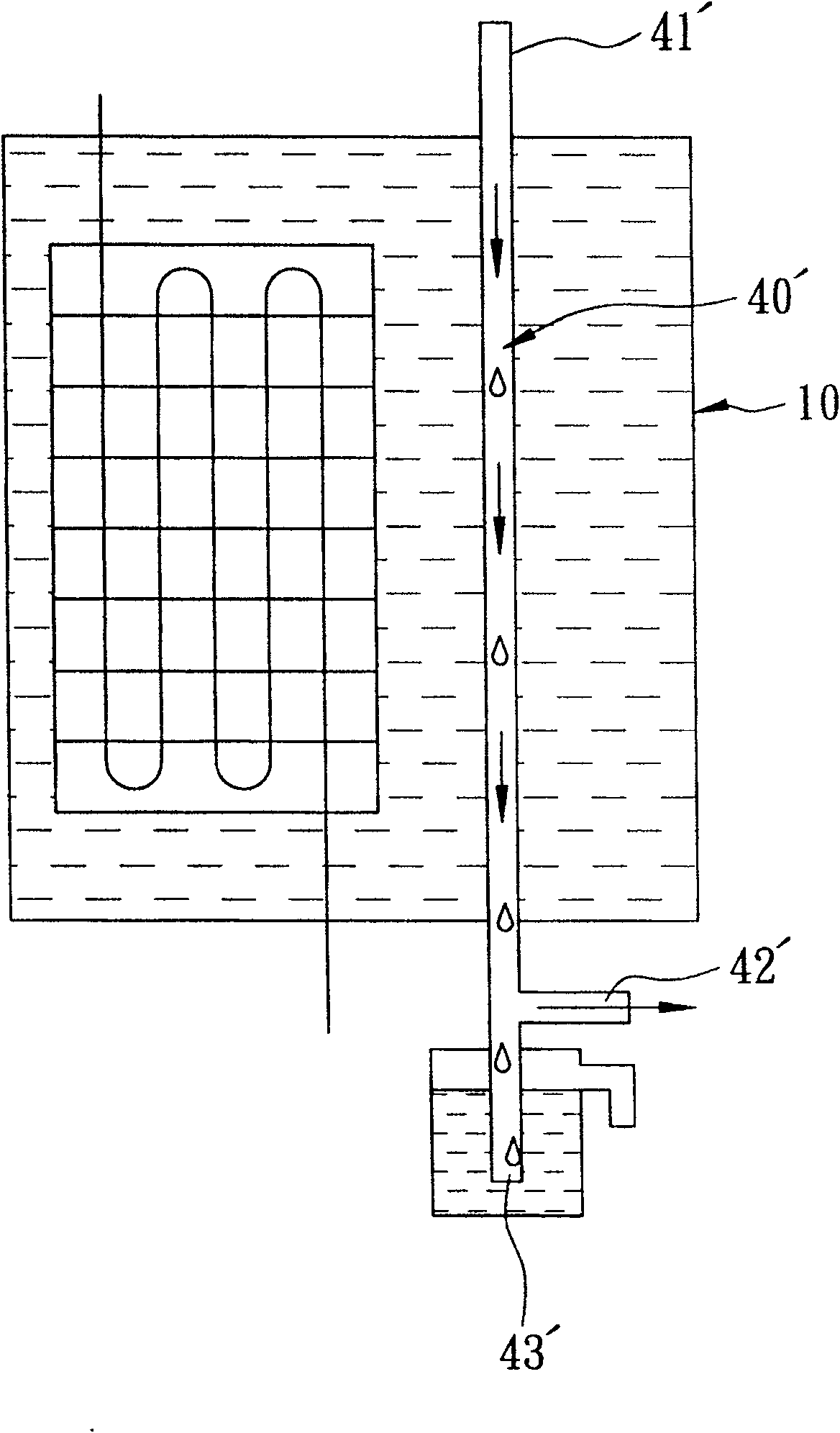

[0014] like figure 2 As shown, the first preferred embodiment of the gas humidity removal device of the present invention includes: a body 10, an evaporator 20 installed inside the body 10, a cooling liquid medium 30 filled in the body 10, a A gas pipeline 40 passing through the main body 10 and a water collection dish 50 disposed at the bottom of the main body 10 .

[0015] The body 10 has a chamber 11 .

[0016] The evaporator 20 is installed in the chamber 11 of the body 10 .

[0017] The cooling liquid medium 30 of this embodiment can be water, and it is pre-filled in the chamber 11 of the body 10, and the liquid level is higher than the evaporator 20, so that the evaporator 20 is fully immersed in the cooling liquid medium 30 .

[0018] The gas pipeline 40 runs through the body 10, and has an air inlet 41 protruding from the top of the body 10, a gas o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com