Zooming lens module group

A zoom lens and lens module technology, applied in installation, optics, instruments, etc., can solve the problems of reducing production costs, disadvantages, and complex mechanical structures, and achieve the effects of reducing production costs, simplifying structures, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The zoom lens module provided by the embodiment of the technical solution will be further described below in conjunction with the accompanying drawings.

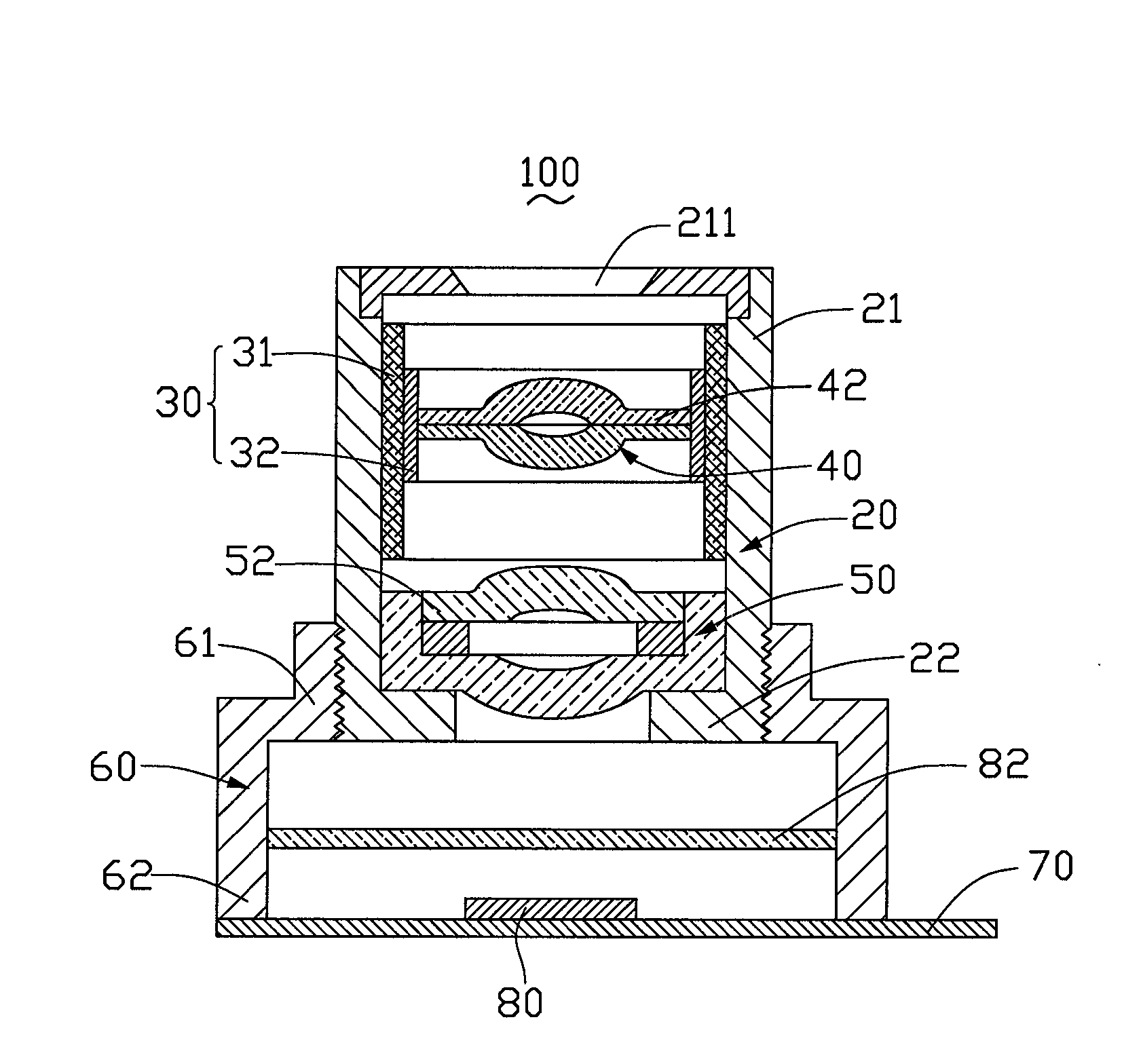

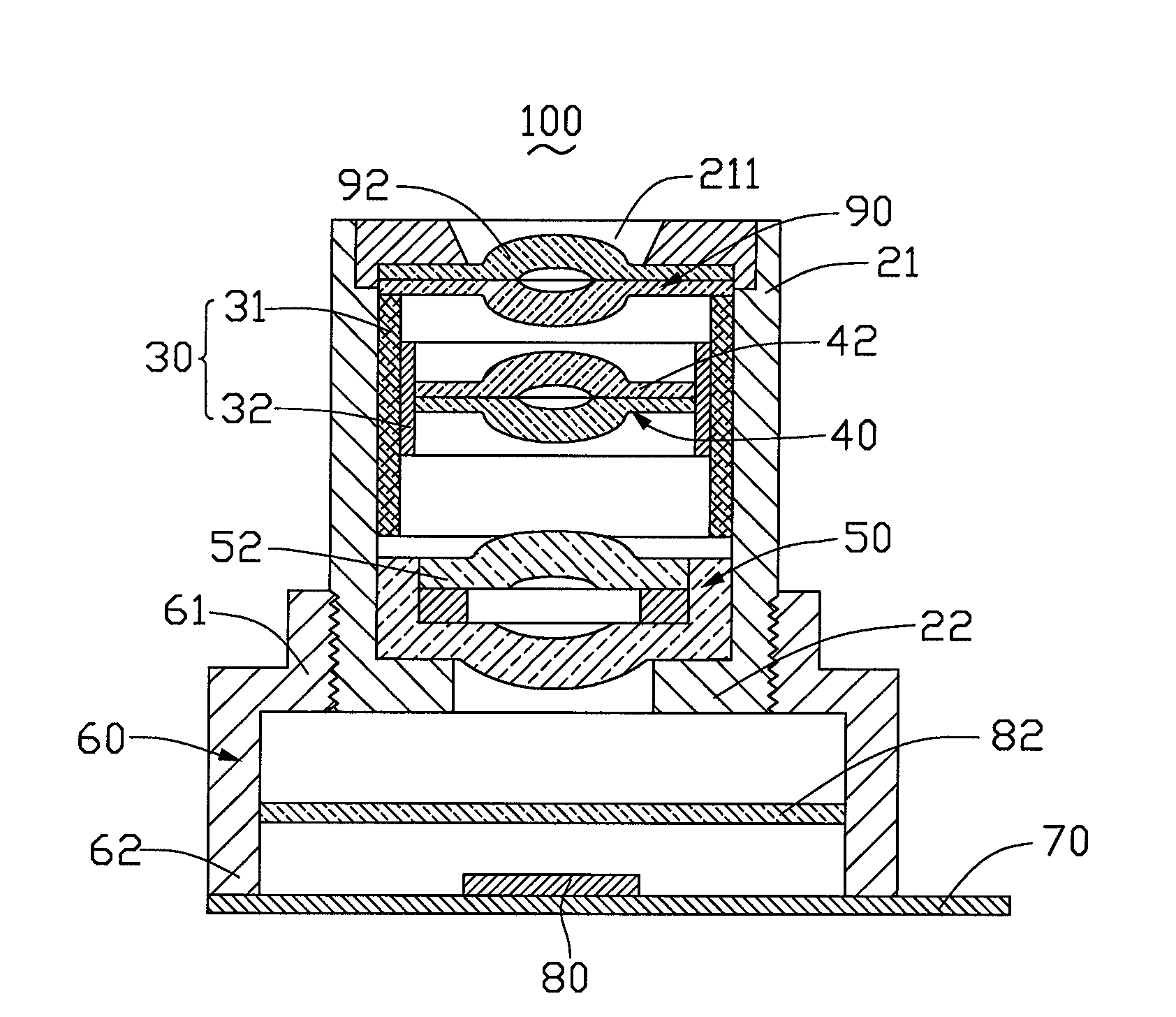

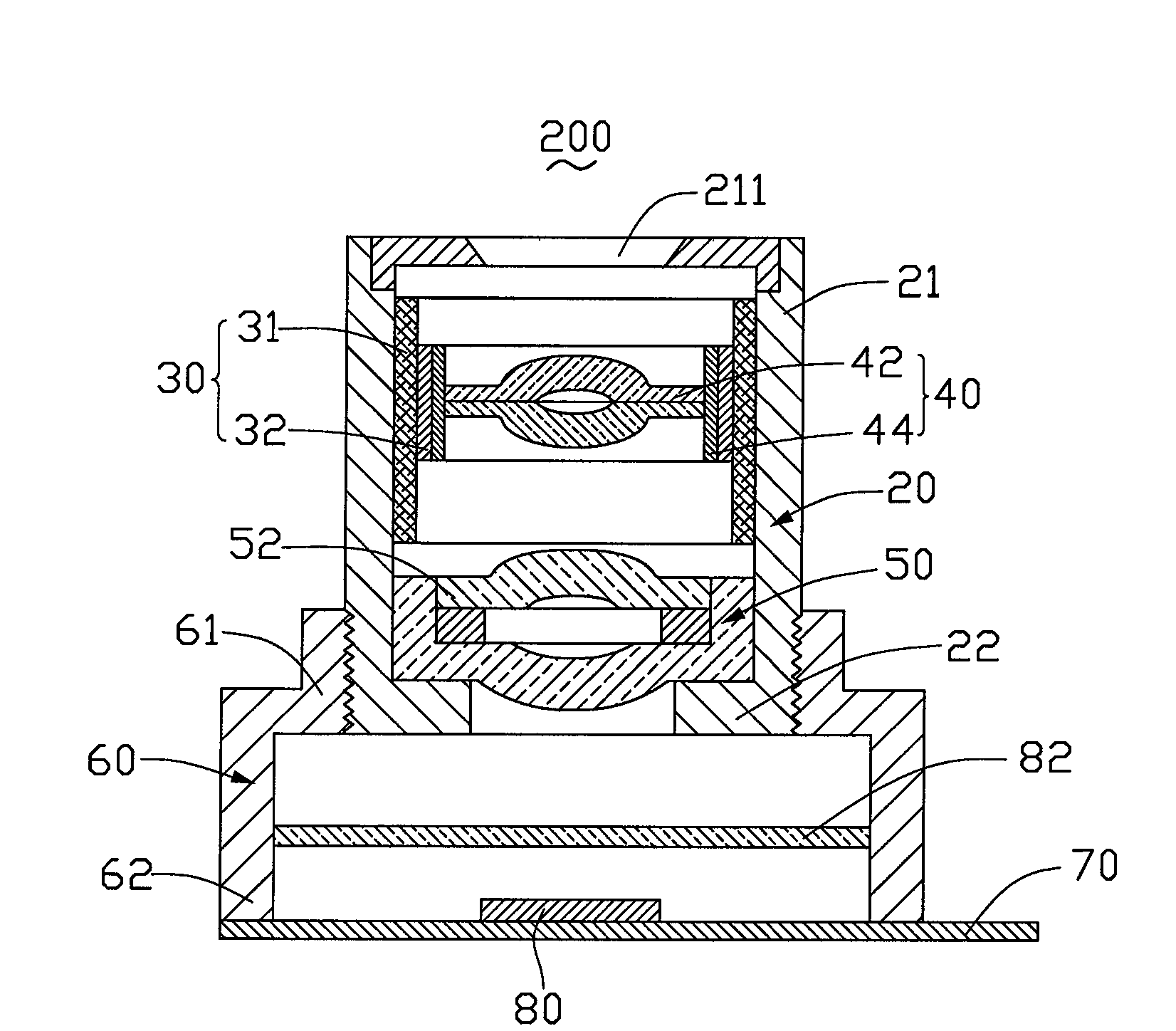

[0012] see figure 1 Embodiment 1 of the technical solution provides a zoom lens module 100 , which includes a lens barrel 20 , a piezoelectric actuator 30 , a first lens module 40 , a second lens module 50 and a lens base 60 .

[0013] The lens barrel 20 is a cylinder for accommodating the piezoelectric actuator 30 , the first lens module 40 and the second lens module 50 . The lens barrel 20 has a first end 21 and a second end 22, the first end 21 is provided with a light entrance hole 211, light can enter the zoom lens module 100 through the light entrance hole 211, and pass through the first The lens module 40 and the second lens module 50 . The inner wall of the first end 21 may be provided with threads for cooperating with and fixing the piezoelectric actuator 30, and the outer wall of the second end 22 may be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com