Fast extraction of plant chemical ingredient

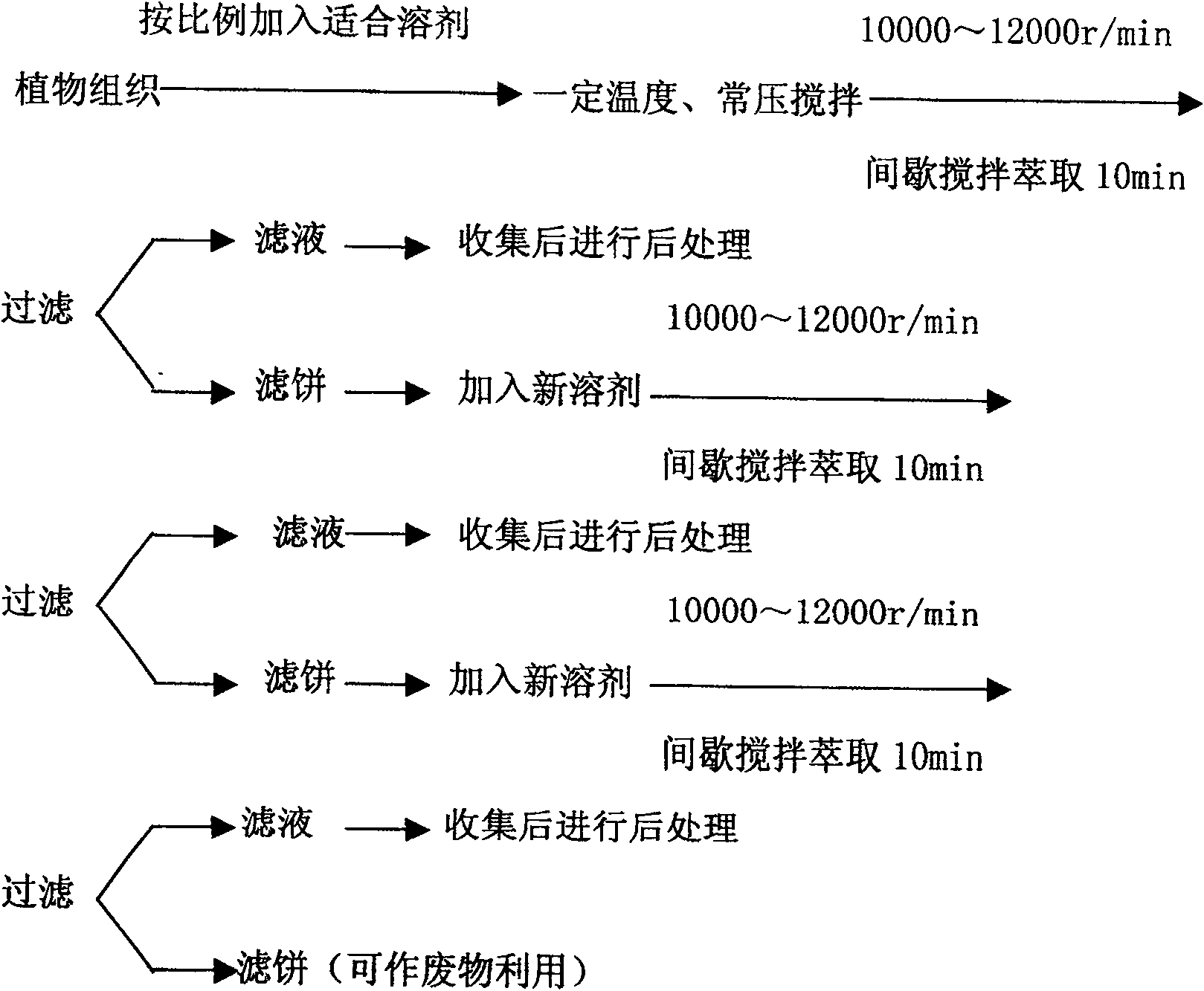

An extraction method and phytochemical technology, applied in the field of plant extraction and separation, can solve the problems of short extraction time and low efficiency in the research and experimental stage, and achieve the effects of reducing the crushing process, saving the extraction time and improving the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A. Add petroleum ether solvent in the ratio of 1:1W / V to the material to be extracted, stir for 0.5min at a speed of 10000r / min and normal pressure, and then stir for 0.5min, then stir for 2min, and then stir for 2min, then stir again for 0.5min min, carry out intermittent stirring and extraction in this way, the stirring time is 3 minutes in total, the intermittent time is 2.5 minutes in total, and then take out and filter;

[0015] B. Add petroleum ether solvent into the filter cake at a ratio of 1:3W / V, stir for 2min at a speed of 12000r / min and normal pressure, then stir for 2min, then stir for 0.5min, pause for 0.5min, and stir again for 0.5min , carry out intermittent stirring and extraction in this way, the stirring time is 3 minutes in total, the intermittent time is 2.5 minutes in total, and then take out and filter;

[0016] C, the filter cake repeats the extraction process described in step B again, repeats the extraction 3 times like this, merges each filtra...

Embodiment 2

[0018] A. Add distilled water at a temperature of 50°C to the material to be extracted at a ratio of 1:3W / V, stir and extract for 2 minutes at a speed of 12000r / min and normal pressure, and then stir for 2 minutes, and then stir again for 2 minutes. Extract for 2 minutes, carry out intermittent stirring and extraction in this way, the stirring time is 6 minutes in total, and the intermittent time is 4 minutes in total, then take out and filter;

[0019] B. Add distilled water at a temperature of 50°C to the filter cake at a ratio of 1:1 W / V, stir and extract for 2 minutes at a speed of 10,000 r / min and normal pressure, pause for 2 minutes, stir for another 2 minutes, pause for 2 minutes, and stir and extract again 2min, carry out intermittent stirring and extraction in this way, the stirring time is 6 minutes in total, the intermittent time is 4 minutes in total, and then take out and filter;

[0020] C, filter cake repeats the extraction process described in step B again, rep...

Embodiment 3

[0022] A. Add normal temperature methanol solvent to the material to be extracted at a ratio of 1:2W / V, stir for 1min at a speed of 11000r / min and normal pressure, and then stir for 1min. Perform intermittent stirring and extraction, the stirring time is 3 minutes in total, the intermittent time is 2 minutes in total, and then take out and filter;

[0023] B. Add methanol solvent at room temperature to the filter cake at a ratio of 1:2W / V, stir for 2min at a speed of 11000r / min and normal pressure, then stir for 2min, then stir for 1.5min, then stir for 1.5min, then stir and extract again for 1.5min , carry out intermittent stirring and extraction in this way, the stirring time is 5 minutes in total, the intermittent time is 3.5 minutes in total, and then take out and filter;

[0024] C, the filter cake repeats the extraction process described in step B again, repeats the extraction 4 times like this, merges each filtrate, obtains extractum after concentrating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com