Mechanical vision locating method

A positioning method and machine vision technology, applied in the directions of instruments, photogrammetry/video surveying, surveying and navigation, etc., can solve the problems of accurate analysis of local parts of interest, insufficient detection accuracy, increased equipment costs, etc. Similarity, low cost, and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The basic principle of the present invention is: use two cameras, wherein, the long-distance camera processes the target object as a whole, shoots the global image of the target object, and detects the interesting part on the captured global image (depending on the needs of the application) ); and then control the manipulator to move the close-range camera to these parts of interest, and take high-precision images for further detailed detection and analysis.

[0020] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

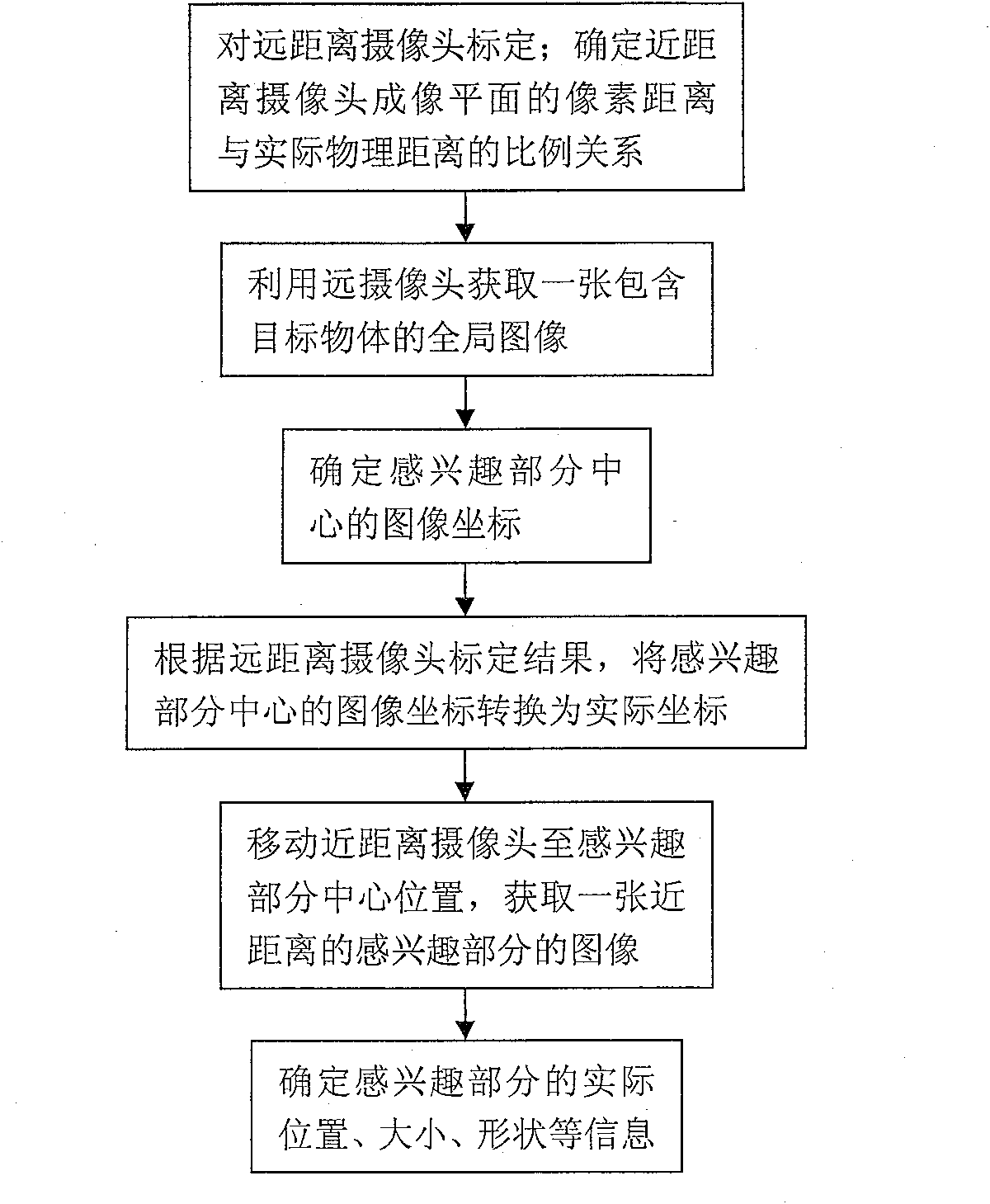

[0021] Such as figure 1 As shown, the machine vision positioning method of the present invention comprises the following steps:

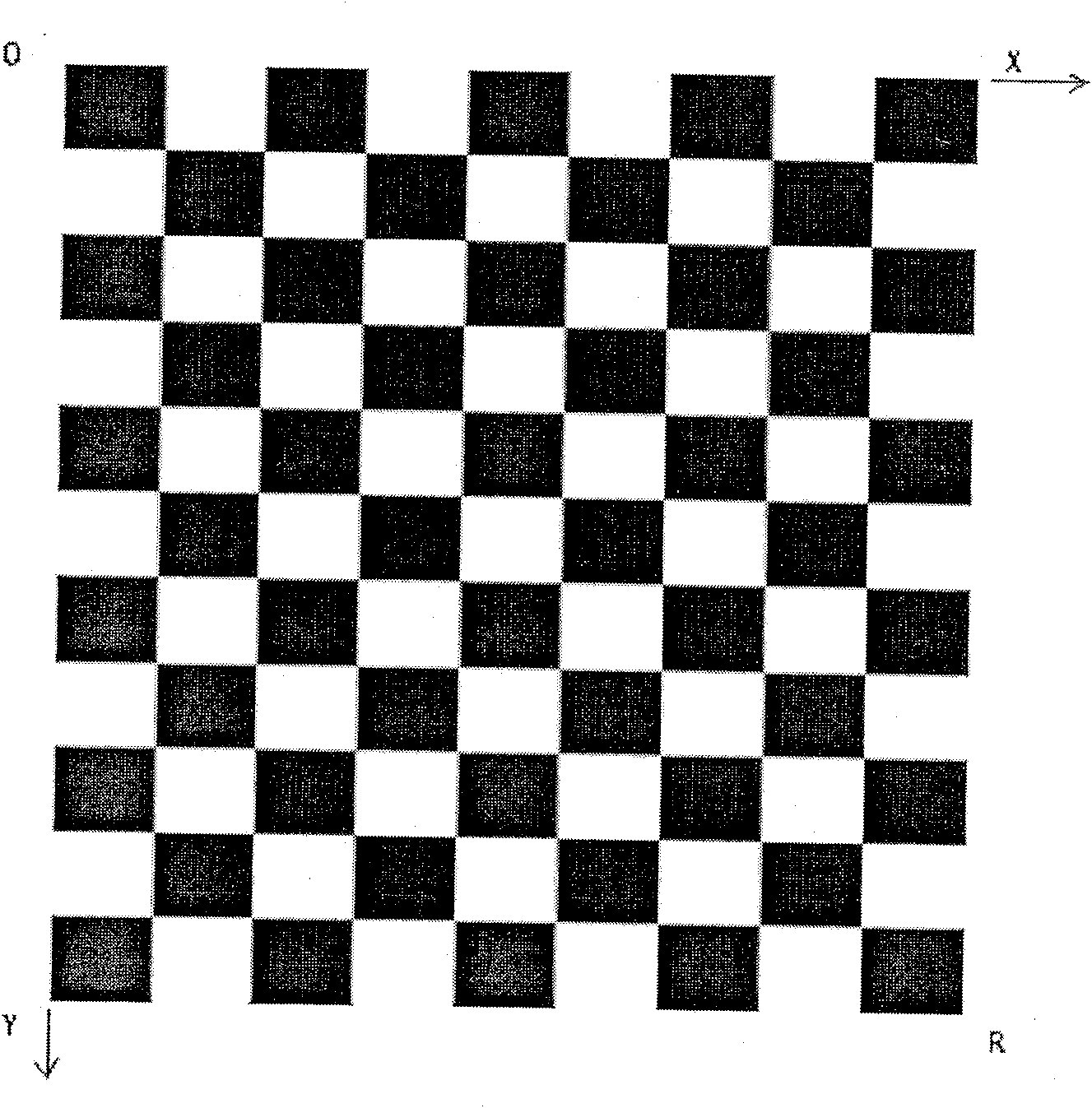

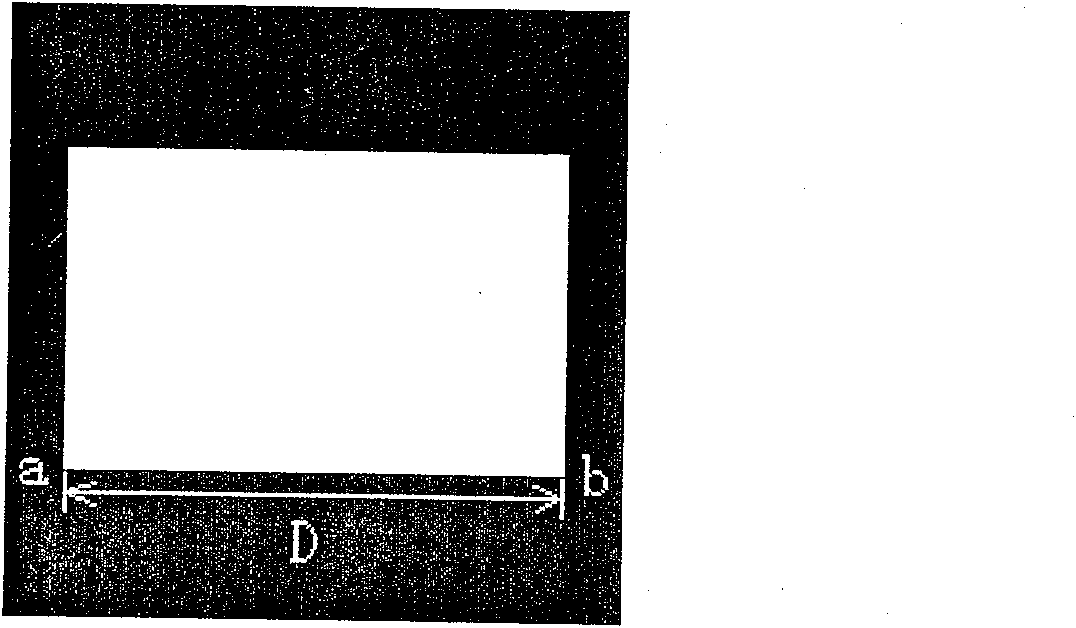

[0022] (1) Calibrate the long-distance camera, determine the corresponding coordinate transformation relationship between its imaging plane and the measured target plane; and determine the proportional relationship between the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com