Sub-roller mechanism of computer plain flat knitter

A flat knitting machine and sub-roller technology, used in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of large power transmission loss, affecting the traction effect, left and right movement, etc., to achieve low power transmission loss. , The structure is simple, the effect of avoiding the movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

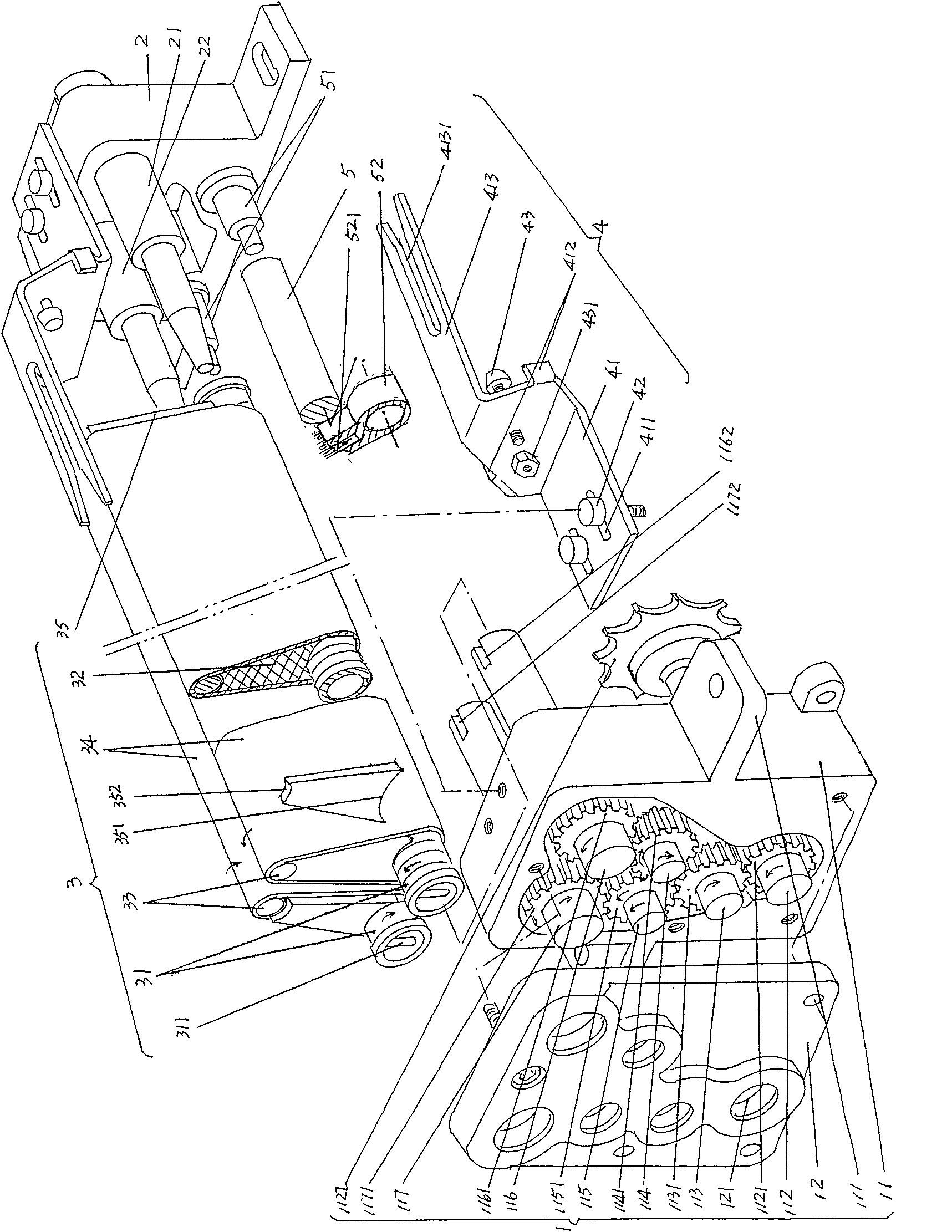

[0021] Please refer to figure 1 A preferred but not absolutely limited power transmission device 1 is given, which is composed of a gear box 11 and a box cover 12. The box cover 12 is fixed to the opening or the box mouth of the gear box 11 by a set of fixing screws. The box cover 12 is provided with shaft holes 121 equal to the number of the shafts mentioned below. The figure shows a total of six shaft holes 121, indicating that six shafts can be pivoted by means of the shaft holes 121. On the box body of the gear box 11, one end of the driving shaft 112, the transition shaft 113, the first and second transmission shafts 114, 115, the first and second roller driving shafts 116, 117 are pivoted from bottom to top. The other end of the shaft, the left end shown in the figure, is pivoted on the aforementioned corresponding shaft hole 121. The drive shaft 112, the transition shaft 113, the first and second drive shafts 114, 115, and the first and second roller drive shafts 116, 117 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com