Reverse converter

A converter and reverse technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of large outline size, complex structure, heavy weight, etc., and achieve compact structure, large stirring power, and low weight Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

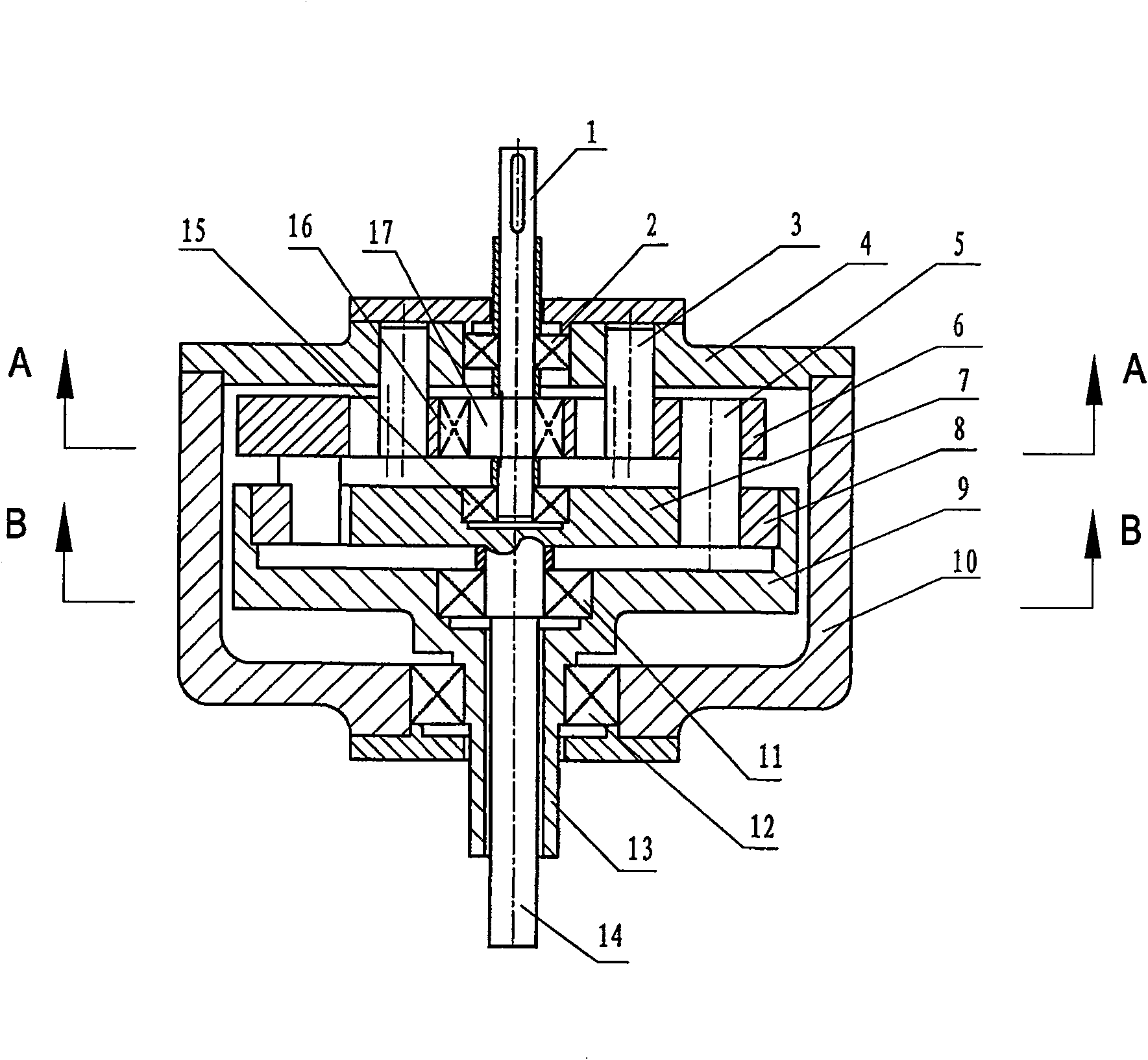

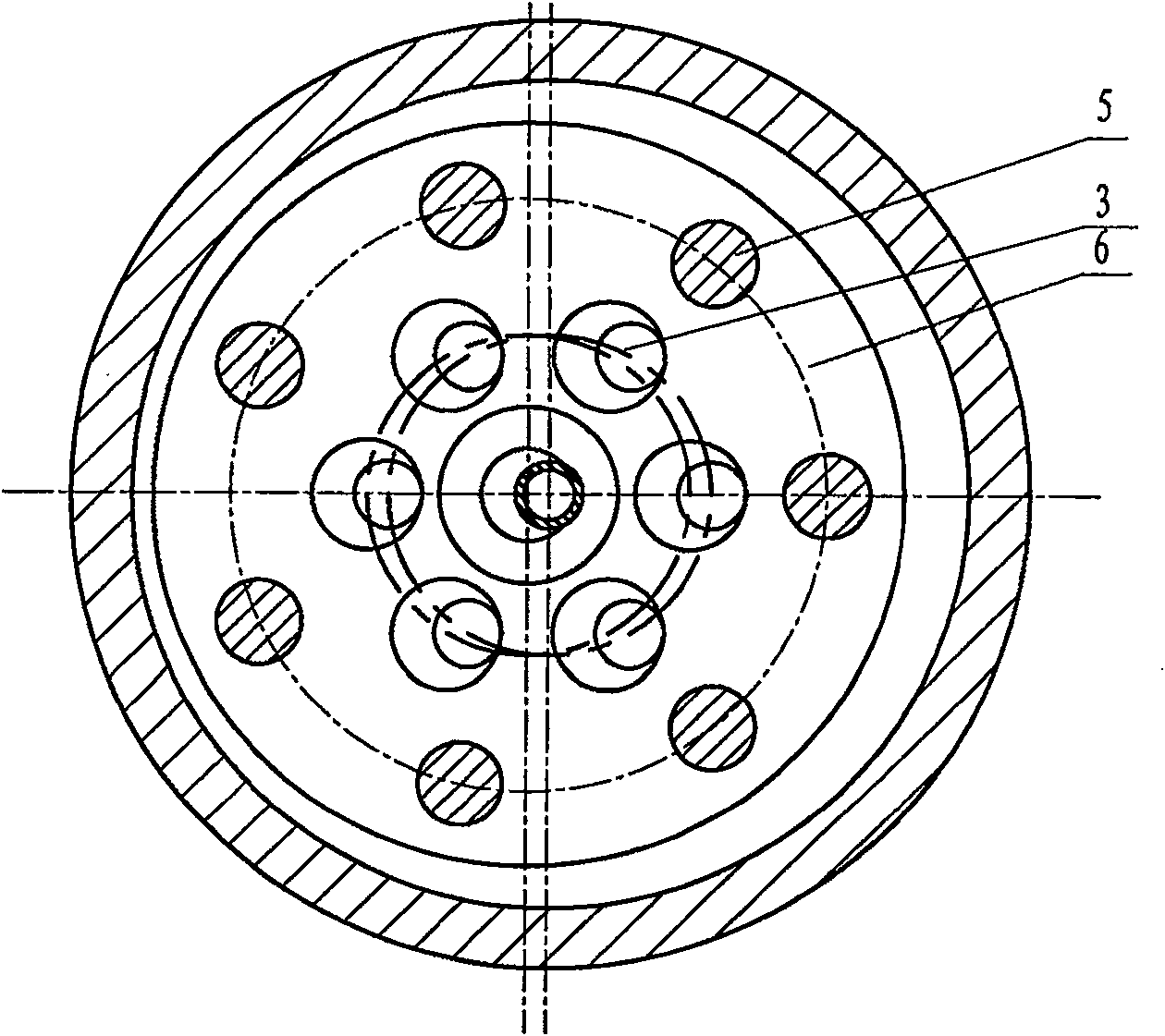

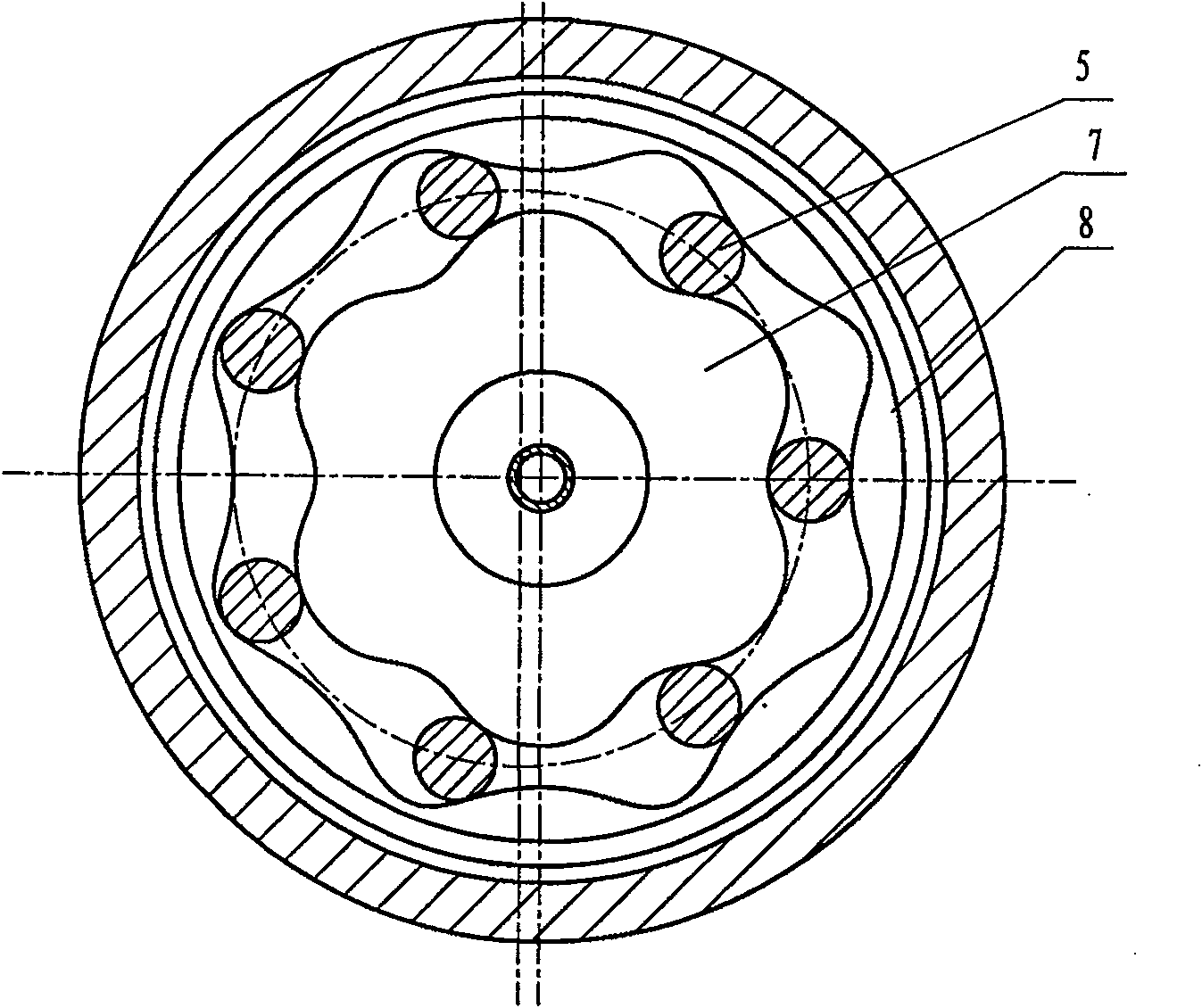

[0037] see figure 1 , 2 , 3. This example is mainly composed of input shaft 1, front bearing 2, output disc bearing 11, sleeve bearing 12, inner rotor bearing 15, eccentric bearing 16, column pin 3, front cover 4, pin teeth 5, and translation disc 6 , Inner rotor 7, outer rotor 8, output disk 9, box 10, output sleeve 13, output shaft 14 and eccentric shaft 17 and other components. The input shaft 1 is fixedly connected with the eccentric shaft 17 as a whole, and is not coaxial with the output shaft 14, but coincides with the axes of the output shaft 14 and the output sleeve 13. The inner rotor 7 and the output shaft 14 are fixedly connected as one. The inner rotor 7 of the epicycloid wheel has 6 teeth less than the pin tooth 5, and the inner cycloid ring gear of the outer rotor 8 has 8 teeth more than the pin tooth 5. The outer rotor 8 is fixedly connected with the output disk 9 and the output sleeve 13 as a whole, and the inner rotor 7 and the outer rotor 8 respectively mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com