Low pressure drop high-temperature gas changing-over valve

A high-temperature gas and reversing valve technology, which is applied to valve details, multi-way valves, valve devices, etc., can solve problems such as large energy loss, large pressure drop, ball valve structure, complex processing and matching, and achieve volume reduction and Weight, small internal space of the valve body, and the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

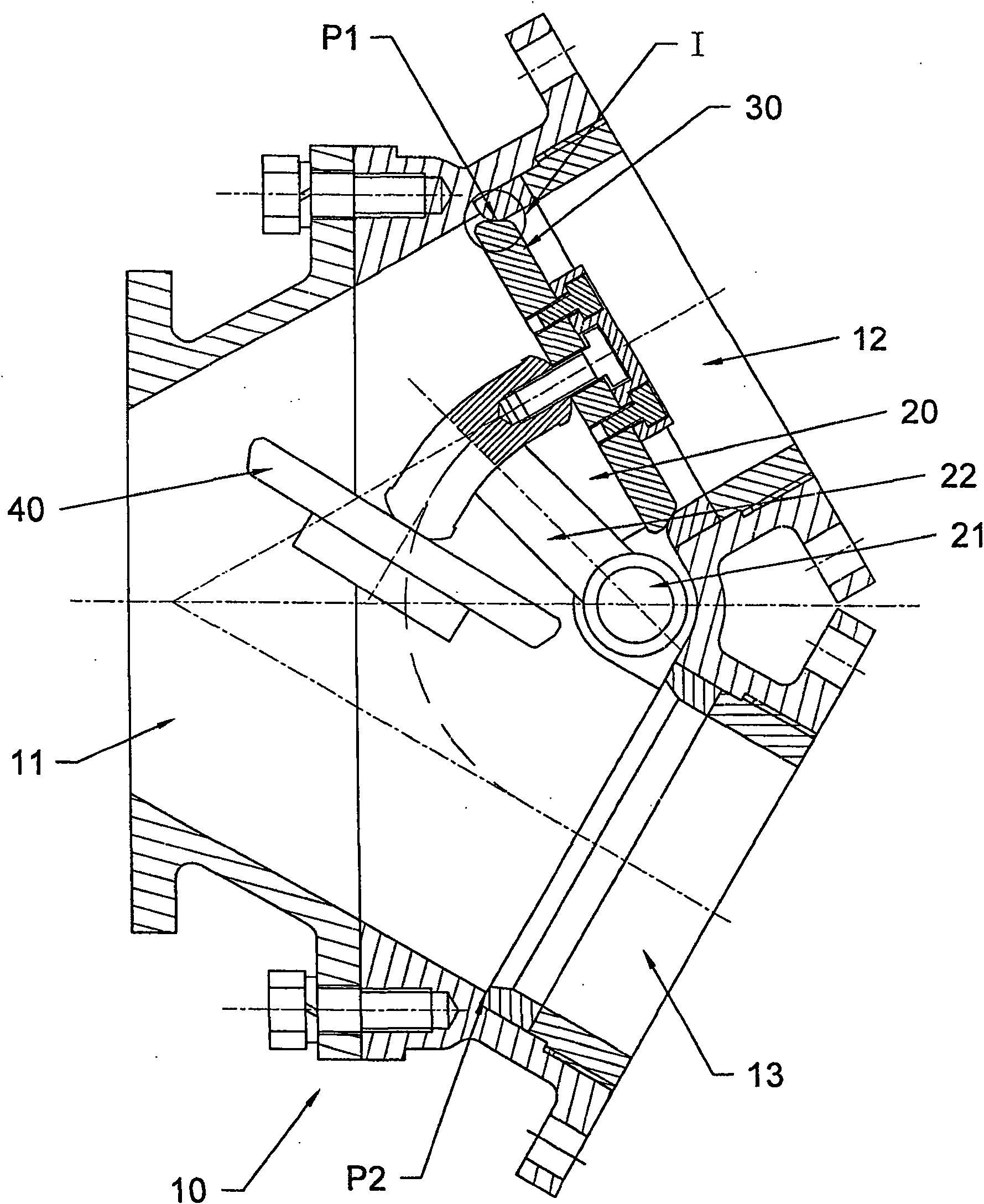

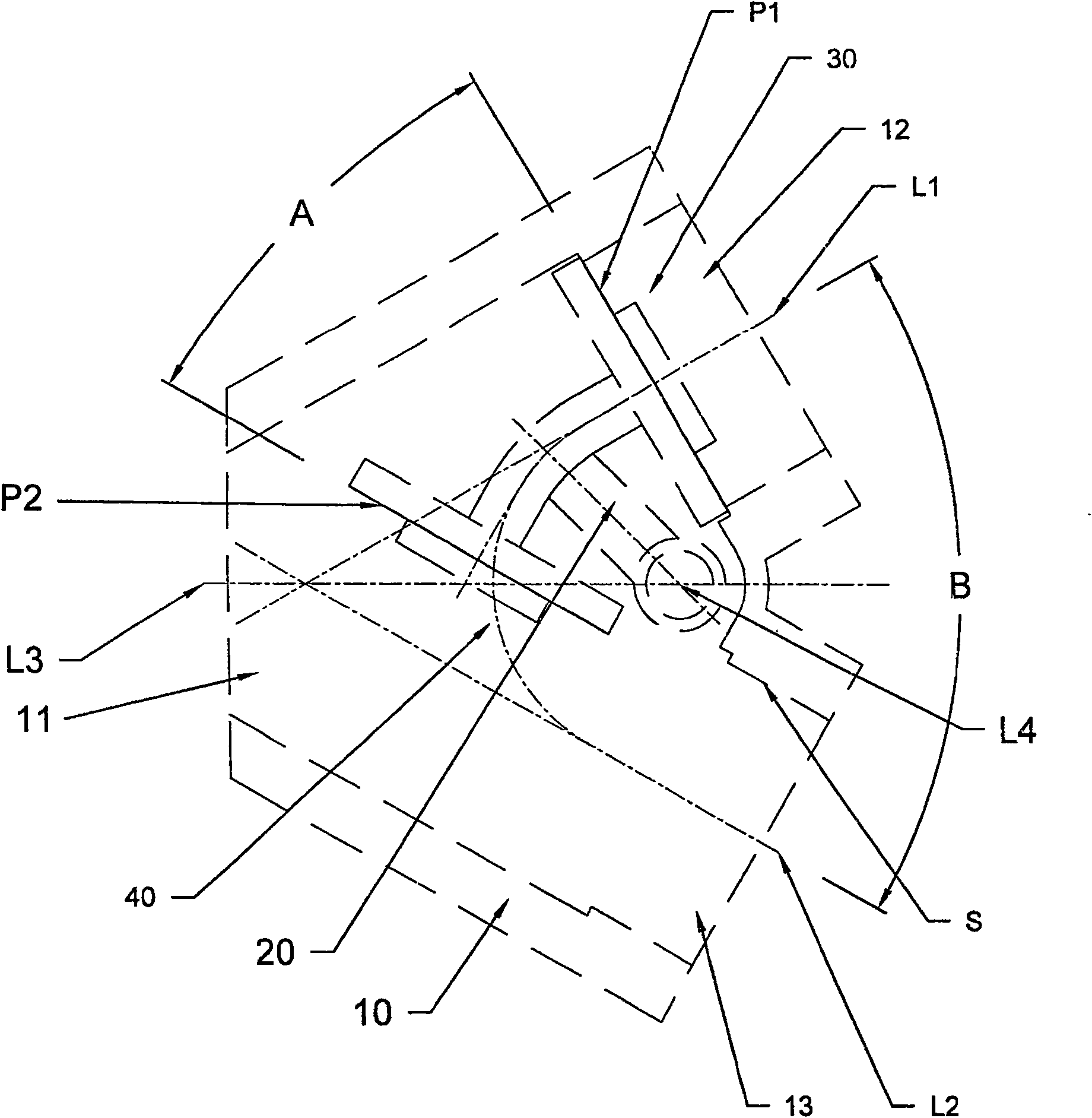

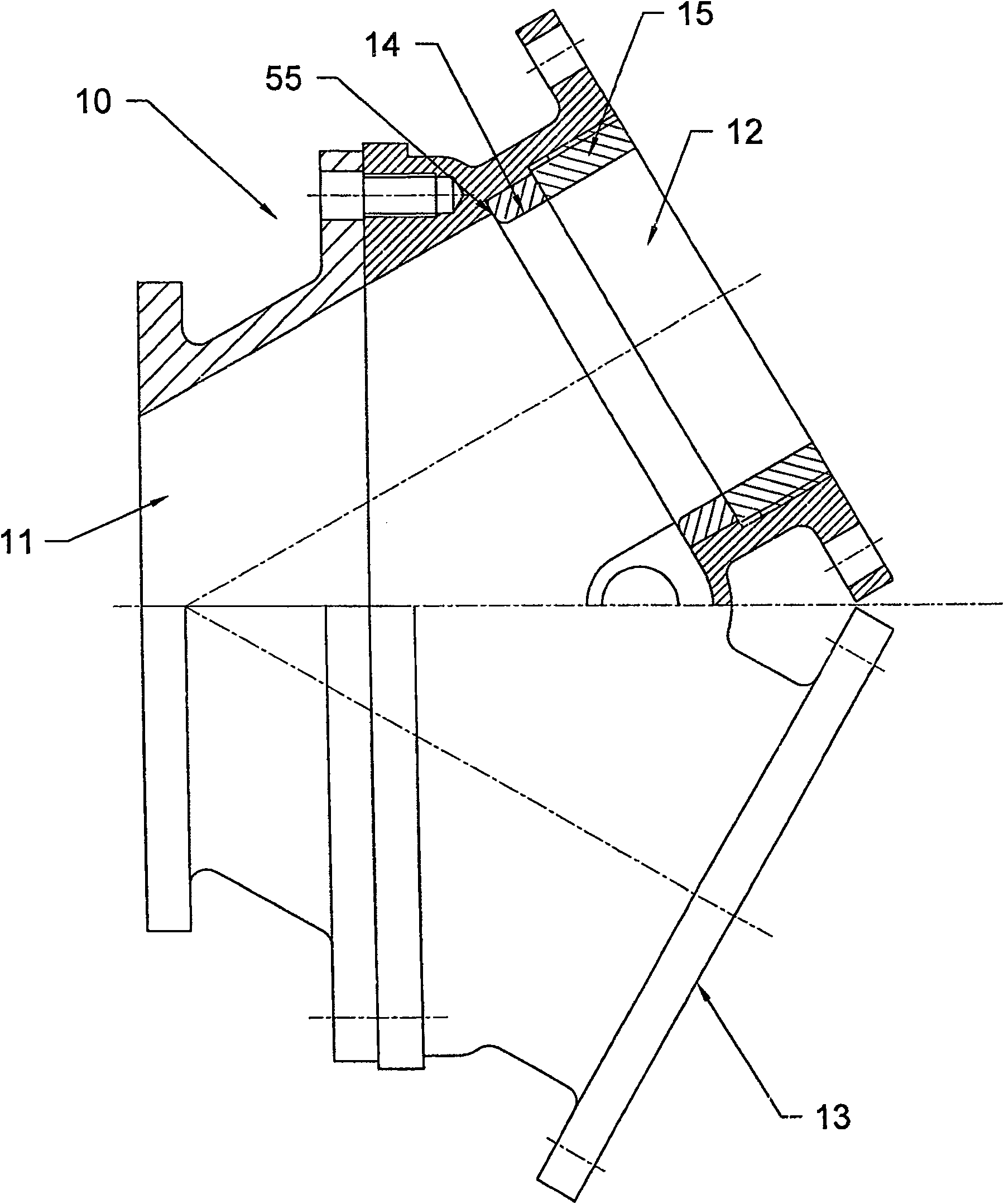

[0027] Such as figure 1 , 2 As shown, in the preferred embodiment of the low pressure drop high temperature gas reversing valve of the present invention, it includes a valve body 10 , a valve stem 20 and two valve covers 30 , 40 . In order to adapt to the high temperature environment of high temperature gas, the valve body 10, valve stem 20 and valve covers 30, 40 are all made of high temperature resistant metal materials, such as stainless steel. Such as figure 1 , 3 As shown, one end of the valve body 10 is provided with an air inlet 11, and the other end is provided with two air outlets 12, 13, and the cross-sectional area of each air outlet is equal to the cross-sectional area of the air inlet, so as to ensure , the exhaust volume of the exhaust port is the same as that of the intake port. The cross-sectional shape of the air outlets 12, 13 and the air inlet 11 is preferably set to a circle, because this shape can withstand greater gas pressure. Preferably, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com