SOI complete silicon structure silicone-oil-filling high-temperature-resistance pressure sensor

A pressure sensor, high temperature resistant technology, applied in high temperature resistant pressure sensor, SOI all-silicon structure filled with silicon oil, high range field, can solve the problems of hysteresis static error, small output signal, piezoelectric pressure sensor is not suitable, etc., to reduce Hysteresis, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

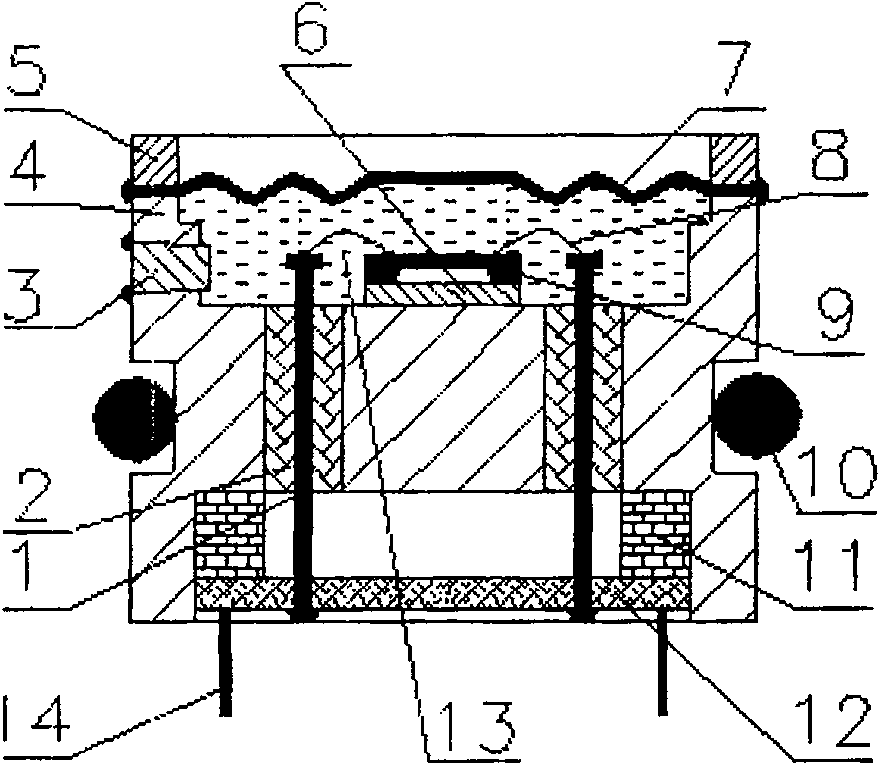

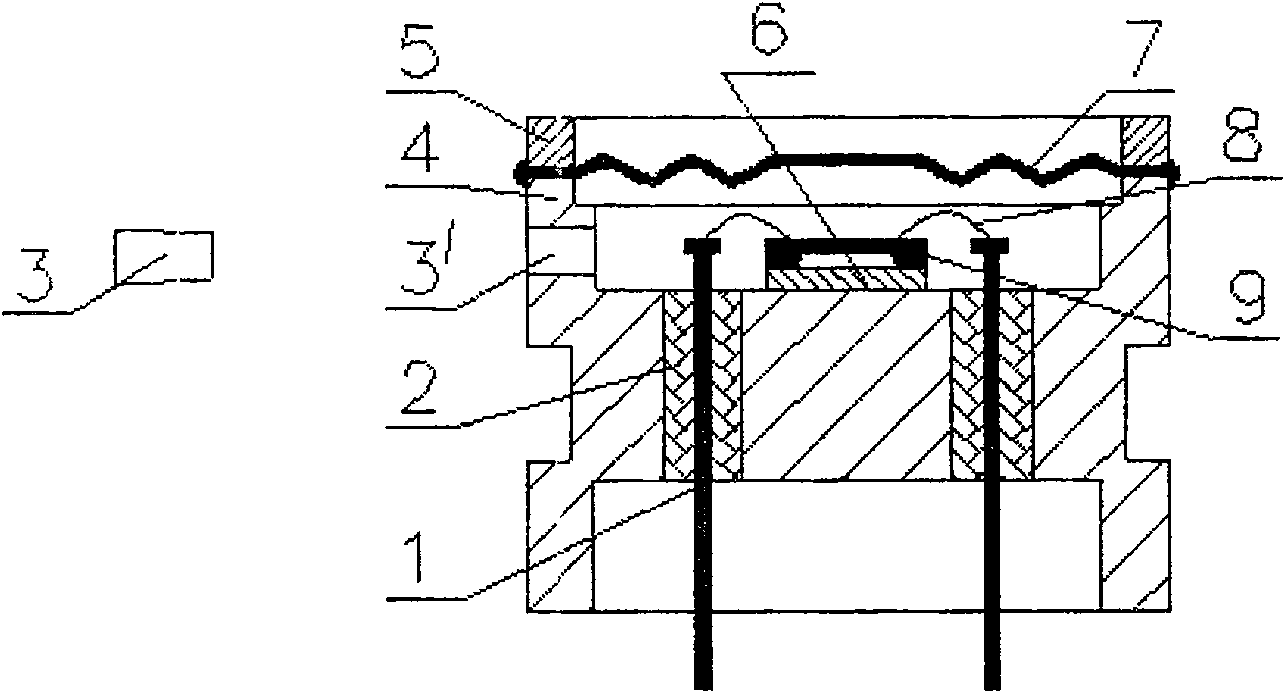

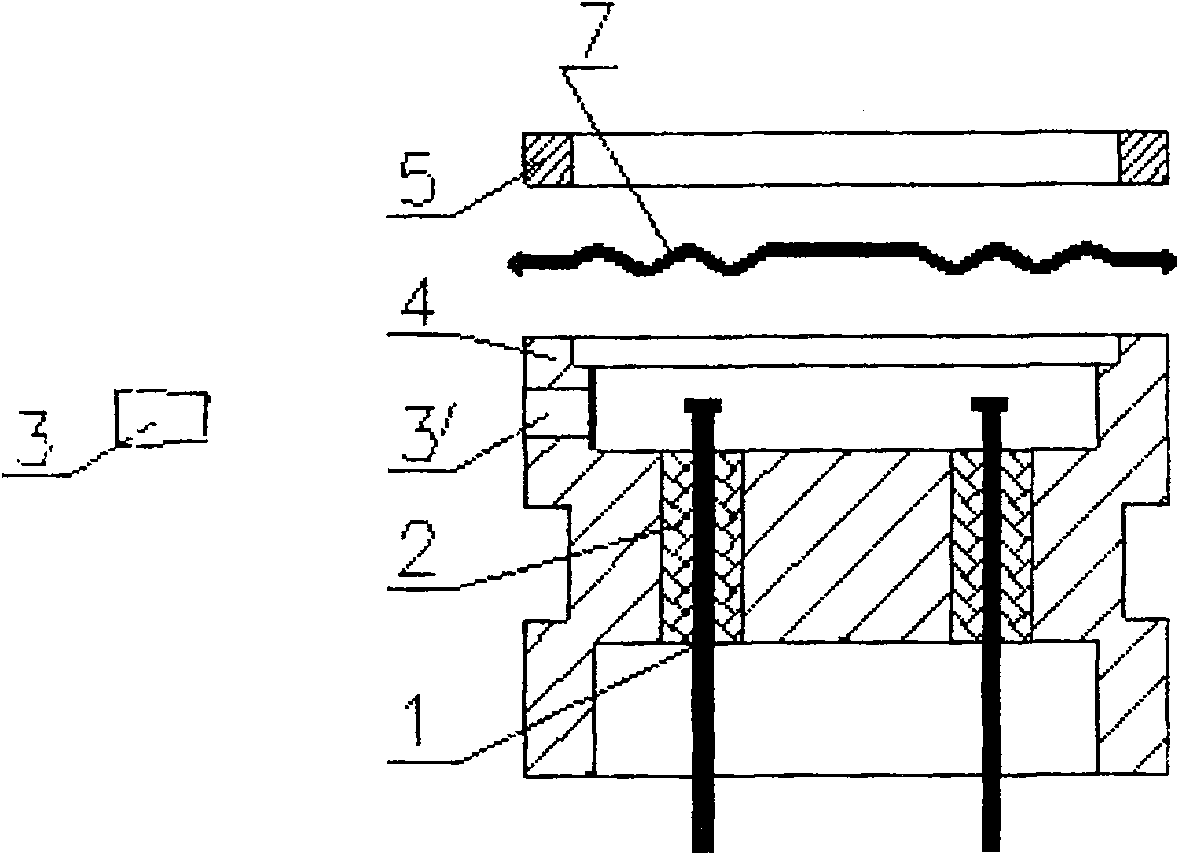

[0016] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] refer to figure 1 , figure 2 and image 3 , the present invention includes a base 4 configured with a cavity, the cavity of the base 4 and a pin hole 3 / The corrugated diaphragm 7 and the pressure ring 5 are sequentially arranged on the cavity of the base 4. The corrugated diaphragm 7, the pressure ring 5 and the base 4 are connected together by laser welding, and the electrode 1 is connected to the base through the glass insulator 2. The base 4 is fixed in phase, and a (100) all-silicon SOI pressure chip 9 is arranged in the cavity of the base 4, and the all-silicon SOI pressure chip 9 is sealed together with the PYREX7740 glass 6 by electrostatic bonding in a vacuum environment , high-temperature silicone oil 13 passes through the pin hole 3 in a vacuum environment / Fill in the cavity of the base 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com