Ultra-thin solar silicon slice and its cutting technology

A technology of solar-grade silicon wafers and cutting technology, which is applied in the field of solar cells, can solve the problems of easily damaged round edges of cylinders, failure to recycle and reduce the pass rate of finished products, etc., to achieve economic benefits, increase output, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

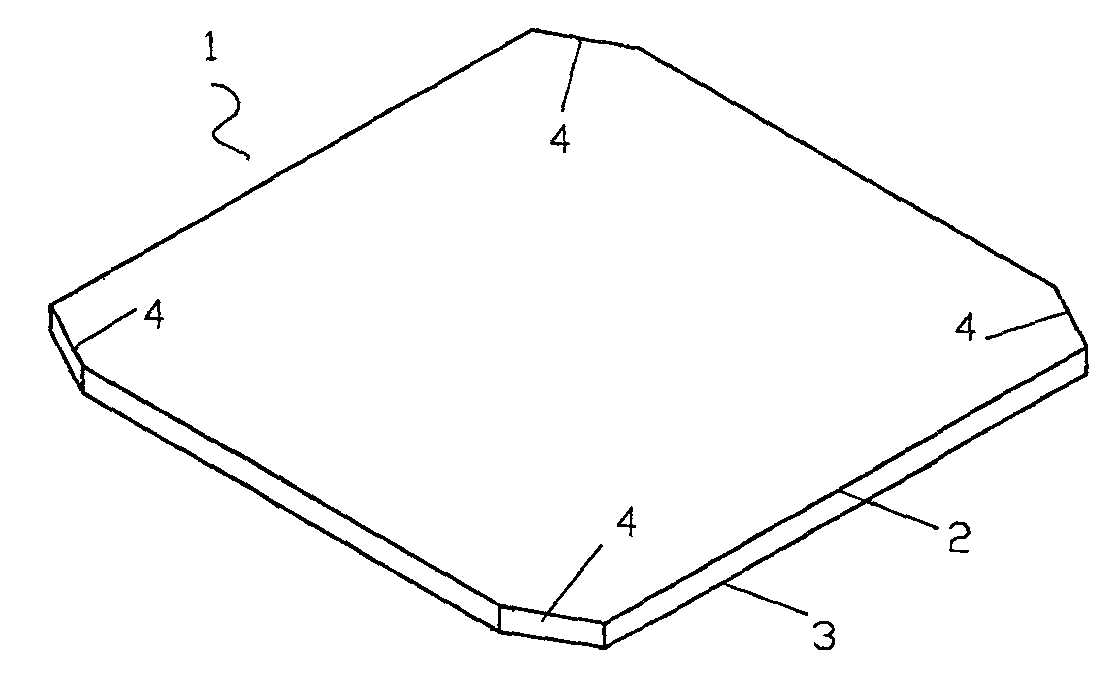

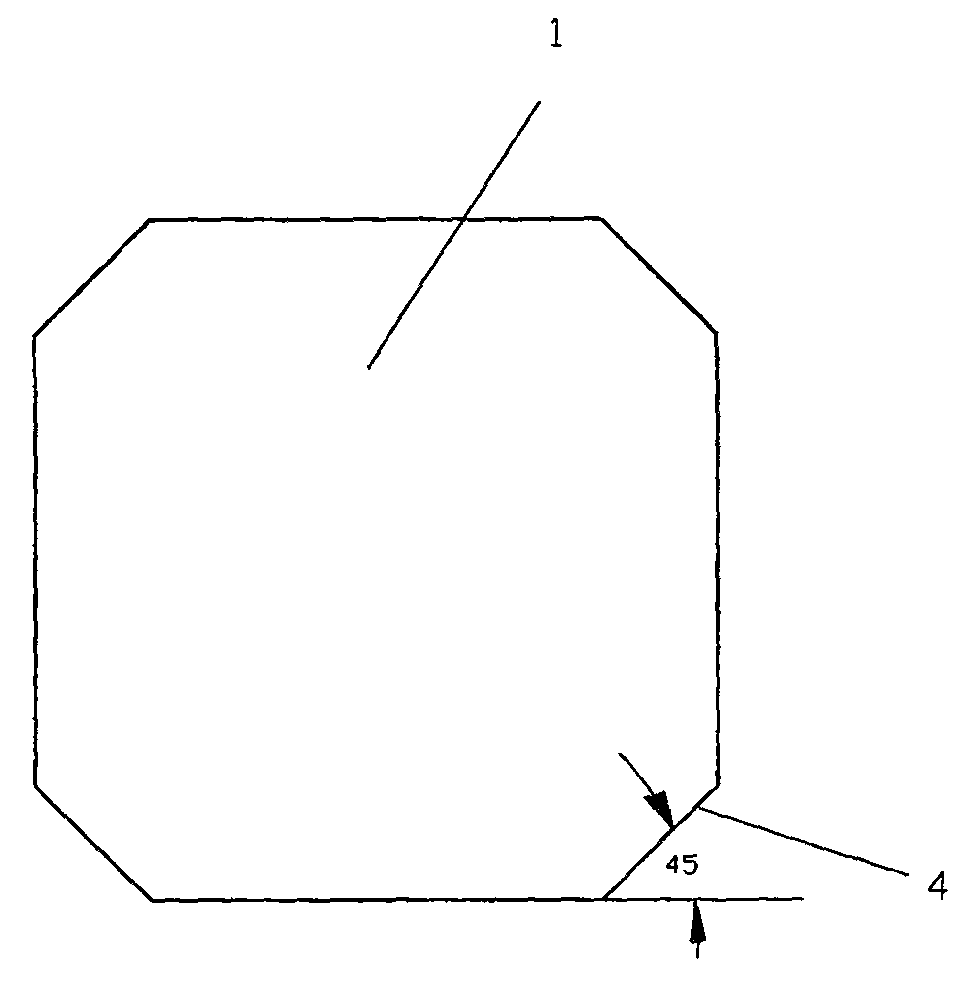

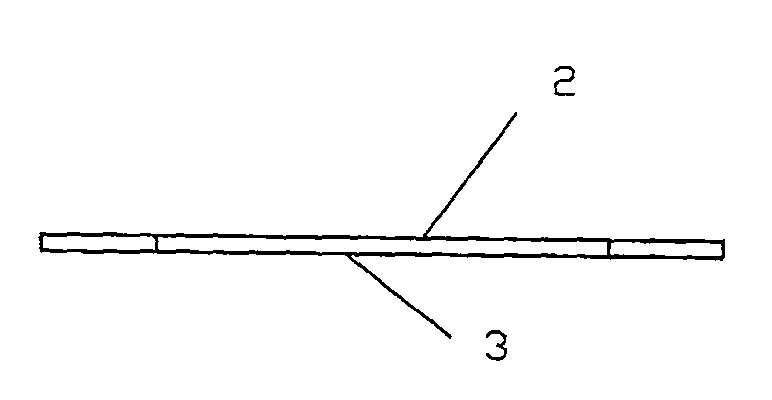

[0014] See figure 1 , figure 2 and image 3 Shown are the perspective view, front view and top view of the ultra-thin solar grade silicon wafer. This embodiment is an ultra-thin solar-grade silicon wafer with a specification of 125mm×125mm, which is composed of upper and lower parallel planes 2 and 3, and its four corners 4 are four identical 45° chamfers. The distance between the upper and lower planes 2 and 3 is within the range of 165 μm-195 μm, the degree of warpage is less than 75 μm, and the surface is smooth, smooth and free from blemishes.

[0015] See Figure 4 Shown is a schematic diagram of the ultra-thin solar-grade silicon wafer cutting process.

[0016] The processing method of this embodiment is to use a silicon crystal ingot squarer to square A = Φ156mm silicon single wafer bar twice and chamfer it twice, and cut it into a square with a cross section of C = 125mm and four identical corners. An octagonal square cylinder with a 45° chamfer and a distance ac...

Embodiment 2

[0022] Embodiment 2 is an ultra-thin solar-grade silicon wafer with a specification of 156mmX156mm. Its main body 1 is composed of upper and lower parallel planes 2 and 3, and its four corners 4 are four identical 45° chamfers. The distance between the upper and lower planes 2 and 3 is within the range of 165 μm-195 μm, the degree of warpage is less than 75 μm, and the surface is smooth, smooth and free from blemishes.

[0023] The processing method of this embodiment is to use a silicon crystal ingot squarer to square A=Φ203mm silicon single wafer rod twice and chamfer it twice, and cut it into a square with a cross section of C=156mm and four identical four corners. 45° chamfer, octagonal square cylinder with distance across sides B=195mm. The cutting process parameters for squaring and chamfering are steel wire speed 11 m / s and workpiece speed 700 microns / min.

[0024] After ultrasonic cleaning and high-purity nitrogen blow-dry the square silicon rod after prescription, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com