Coating machine for preparing digital transfer printing printed paper and preparation method thereof

A technology of digital transfer and printing paper, applied in paper, physical processing paper, coating with specific visual effect, etc., can solve the problems such as affecting the forming quality and use effect of printing paper, slow feeding speed of paint, affecting production efficiency, etc. Achieve high-speed mass production, ensure smoothness, and improve the effect of transfer printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

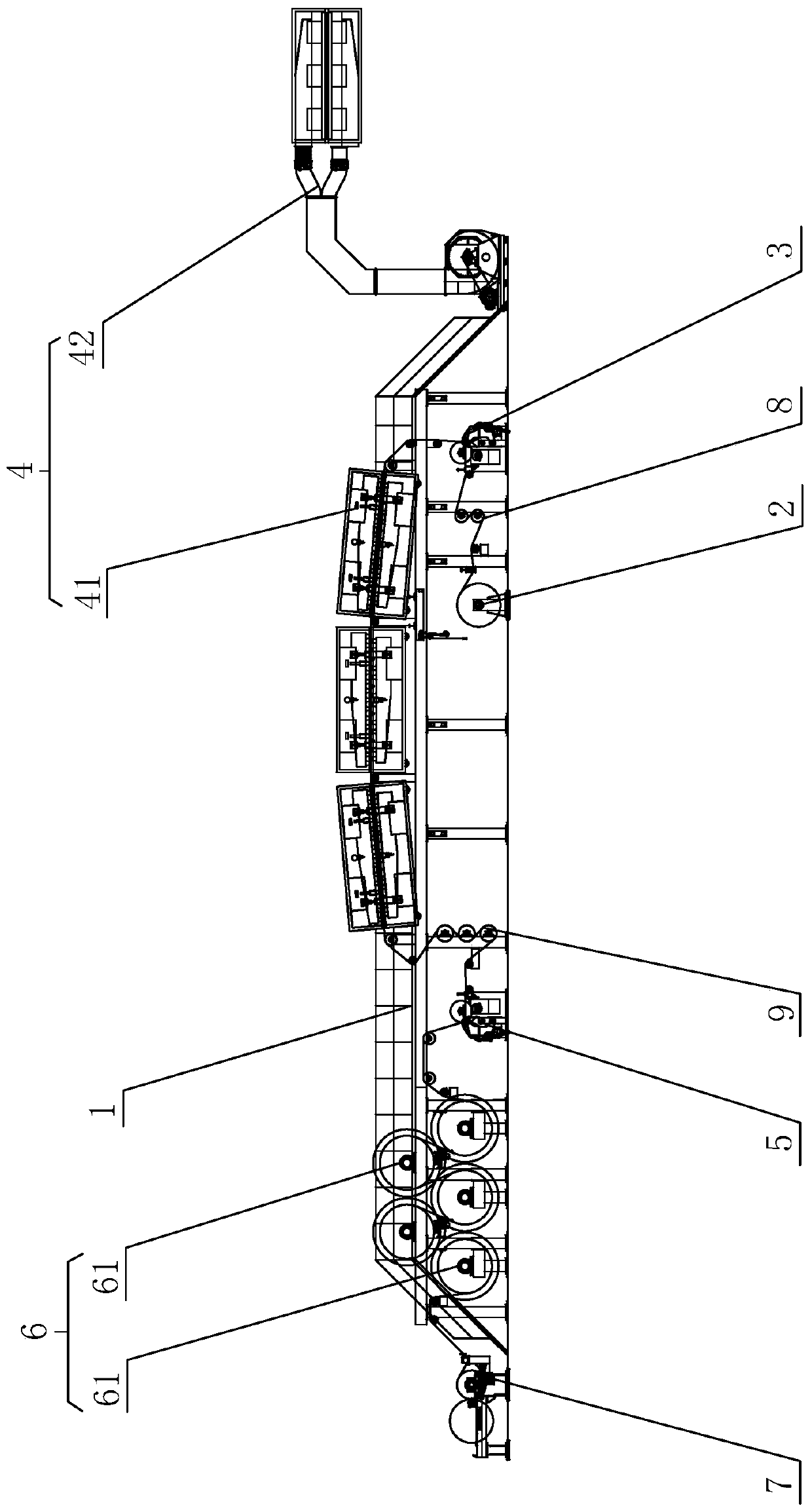

[0046] refer to figure 1, is a coating machine for preparing digital transfer printing paper disclosed by the present invention, comprising a double-layer frame 1, the double-layer frame 1 is a steel structure rectangular parallelepiped frame, and one end of the lower layer of the double-layer frame 1 is sequentially Fixedly equipped with automatic paper receiving and placing rack 2 and front soft scraper coater 3, the upper layer of the double-layer frame 1 is fixed with a hot air drying system 4 directly above the automatic paper receiving and placing rack 2, and the double-layer rack 1 The other end of the lower layer is fixed with a rear soft scraper coater 5, a drying group 6 and an automatic paper delivery rack 7 in sequence, and the front soft scraper coater 3 and the automatic paper delivery rack 7 are respectively located at the bottom of the double-layer frame 1. ends. The base paper passes through the automatic paper receiving rack 2, the front soft blade coater 3,...

Embodiment 2

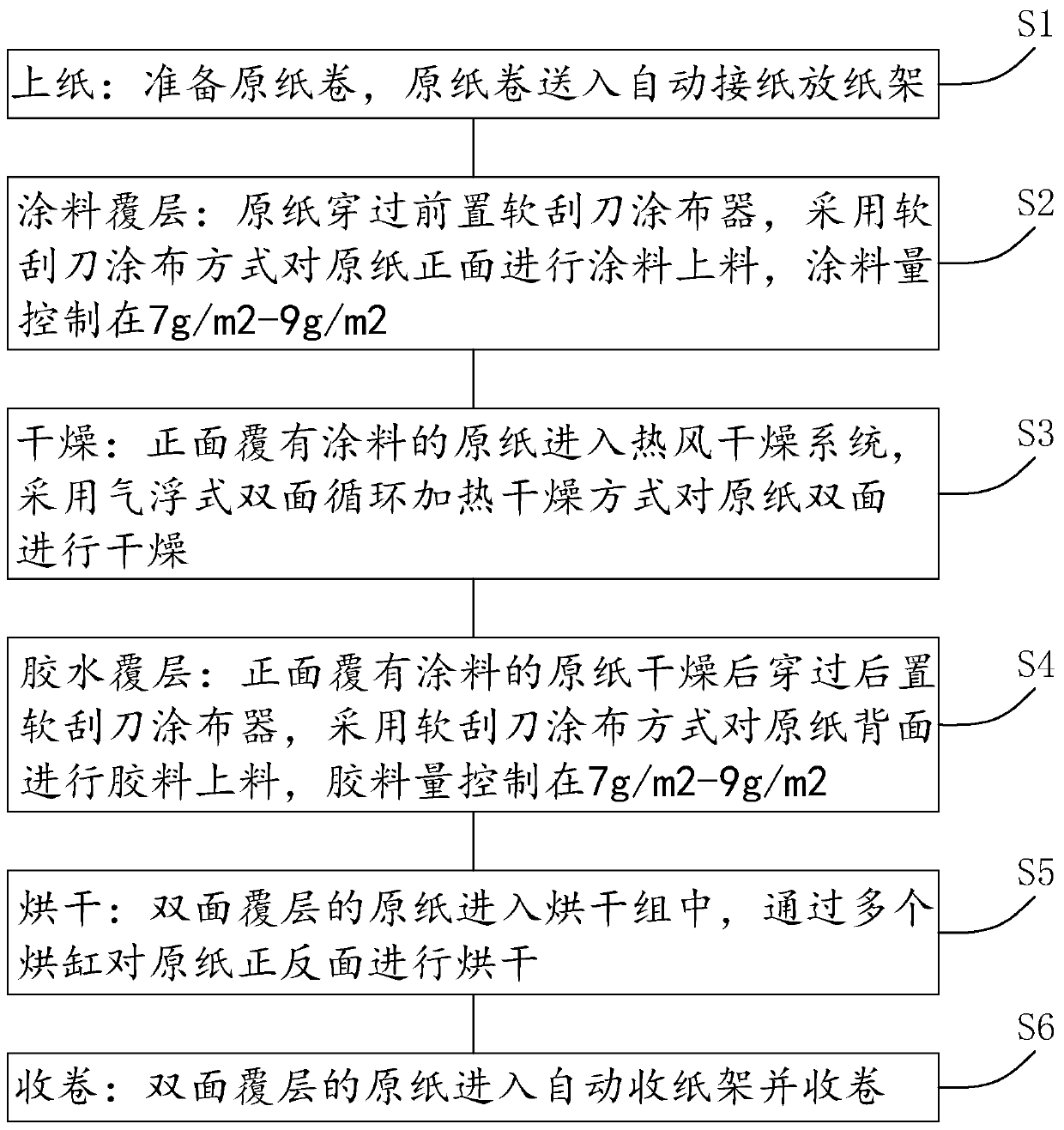

[0059] refer to figure 2 , a method for preparing thermal sublimation digital transfer printing paper, comprising the steps of:

[0060] Step 1, paper loading: prepare the original paper roll, and send the original paper roll to the automatic paper splicing and paper rack 2;

[0061] Step 2, coating coating: the base paper passes through the front soft blade coater 3, and the front side of the base paper is coated with a soft blade coating method, and the amount of coating is controlled at 7g / m 2 -9g / m 2 ;

[0062] Step 3. Drying: The base paper covered with paint on the front side enters the hot air drying system 4, and the double-sided circulation heating drying method of air flotation is used to dry both sides of the base paper;

[0063] Step 4, Glue coating: After drying, the base paper covered with paint on the front side passes through the rear soft scraper coater 5, and the back of the base paper is coated with glue by using a soft scraper coating method, and the am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com