Production and preparation process of aviation O-state coated 7-series aluminum alloy skin thin plate

A preparation process and aluminum alloy technology, which is applied in the field of aerospace aluminum alloys, can solve the problems that the overall performance of the subsequent application state cannot meet the technical design requirements, cracks are easy to occur, and the performance is uneven.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

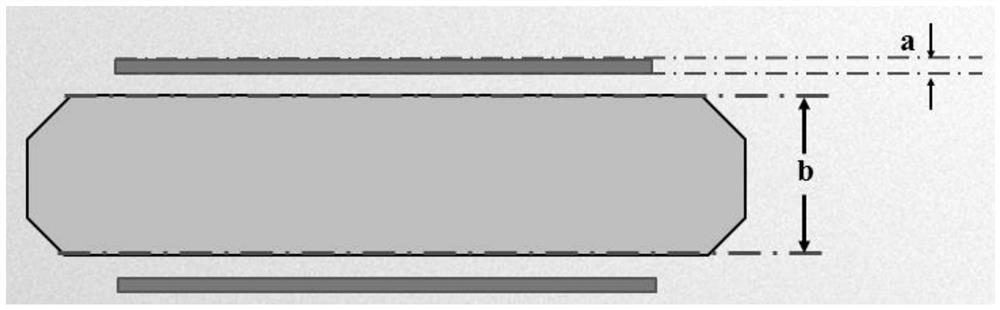

[0031] 1, the ingot size (400-620mm (thick) * 1200-2200mm (wide) * 2000-8000mm (long) flat ingot that the present invention adopts is produced by semi-continuous casting, and the control alloy composition scope is: Si content is lower than 0.08 %, Fe content below 0.15%, Zn content 5.6%-5.9%, Cu content 1.3%-1.6%, Mg content 2.4%-2.7%, Mn content below 0.1%, Cr content 0.18%-0.21%, Ti content Less than 0.1%, other impurity elements, individual not more than 0.05%, total not more than 0.15%.

[0032]2. The preparation method of flat ingot alloy: raw materials are prepared according to the composition and mass percentage of the aluminum alloy sheet. Put the raw materials in the smelting process, add remelted aluminum ingots and scraps of the same alloy, smelt at 740 ° C, add the covering agent after melting, and when 60-70% of the aluminum alloy raw materials are melted, turn on the electromagnetic stirring, and proceed after melting Composition adjustment, adding master alloys...

Embodiment 2

[0042] 1, the ingot size (400-620mm (thick) * 1200-2200mm (wide) * 2000-8000mm (long) flat ingot that the present invention adopts is produced by semi-continuous casting, and the control alloy composition scope is: Si content is lower than 0.08 %, Fe content below 0.15%, Zn content 5.6%-5.9%, Cu content 1.3%-1.6%, Mg content 2.4%-2.7%, Mn content below 0.1%, Cr content 0.18%-0.21%, Ti content Less than 0.1%, other impurity elements, individual not more than 0.05%, total not more than 0.15%.

[0043] 2. The preparation method of flat ingot alloy: raw materials are prepared according to the composition and mass percentage of the aluminum alloy sheet. Put the raw materials in the smelting process, add remelted aluminum ingots and scraps of the same alloy, smelt at 740 ° C, add the covering agent after melting, and when 60-70% of the aluminum alloy raw materials are melted, turn on the electromagnetic stirring, and proceed after melting Composition adjustment, adding master alloy...

Embodiment 3

[0053] 1, the ingot size (400-620mm (thick) * 1200-2200mm (wide) * 2000-8000mm (long) flat ingot that the present invention adopts is produced by semi-continuous casting, and the control alloy composition scope is: Si content is lower than 0.08 %, Fe content below 0.15%, Zn content 5.6%-5.9%, Cu content 1.3%-1.6%, Mg content 2.4%-2.7%, Mn content below 0.1%, Cr content 0.18%-0.21%, Ti content Less than 0.1%, other impurity elements, individual not more than 0.05%, total not more than 0.15%.

[0054] 2. The preparation method of flat ingot alloy: raw materials are prepared according to the composition and mass percentage of the aluminum alloy sheet. Put the raw materials in the smelting process, add remelted aluminum ingots and scraps of the same alloy, smelt at 740 ° C, add the covering agent after melting, and when 60-70% of the aluminum alloy raw materials are melted, turn on the electromagnetic stirring, and proceed after melting Composition adjustment, adding master alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com